فولاذ البراغي عالي القوة: فهم العلم وراء السحابات القوية

البراغي عالية القوة هي الأبطال الخفيين للبناء والهندسة الحديثة. فهي تحمل أوزانًا ضخمة، وتقاوم قوى هائلة، وتحافظ على سلامة الهياكل - بدءًا من ناطحات السحاب الشاهقة والجسور الطويلة وحتى توربينات الرياح القوية وآلات المصانع الثقيلة. وعلى الرغم من أننا نراها في كل مكان، إلا أن العلم وراء ما يجعل هذه المثبتات قوية للغاية - الفولاذ عالي القوة - معقد ومصمم بعناية. هذا ليس فولاذًا عاديًا؛ إنه نوع خاص من المواد المصنوعة من مزيج دقيق من المواد الكيميائية وعمليات تسخين يتم التحكم فيها بعناية. هذا المزيج من المضافات المعدنية والمعالجة الحرارية يحول الفولاذ العادي إلى جزء عالي الأداء يمكنه التعامل مع المتطلبات الصعبة للمهام الحرجة.

تقدم هذه المقالة دليلاً تقنياً كاملاً للمهندسين وعلماء المواد وأخصائيي المشتريات. سنقوم بتفصيل علم المواد وراء فولاذ البراغي عالي القوة، والانتقال من المبادئ الأساسية إلى الاستخدام الواقعي. الهدف من ذلك هو تزويدك بالمعرفة العميقة اللازمة لاختيار هذه الأجزاء المهمة وتحديدها واستكشاف الأخطاء وإصلاحها بفعالية. سوف نستكشف:

- علم المعادن الأساسي ودور المضافات المعدنية الرئيسية.

- التصنيع الحرج و عمليات المعالجة الحرارية التي تخلق القوة

- دليل لفهم المعايير الدولية الشائعة ودرجات الصلب.

- نظرة تفصيلية على الخواص الميكانيكية التي تتجاوز قوة الشد البسيطة.

- تحليل عملي لأنماط الفشل الشائعة وأسبابها الجذرية.

- إطار عمل لاختيار الفولاذ المناسب لتطبيقك.

علم القوة

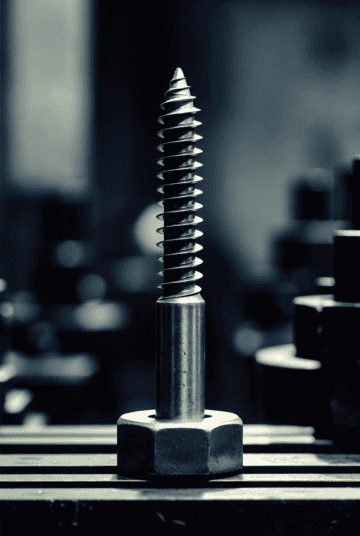

يبدأ الأداء المذهل للمسامير عالية القوة من المستوى الذري. إن الأساس لمعظم فولاذ البراغي عالي القوة هو فولاذ متوسط الكربون، يحتوي عادةً على 0.301 تيرابايت إلى 0.501 تيرابايت إلى 0.501 تيرابايت من الكربون بالوزن. يوفر هذا المحتوى الكربوني خط أساس متين للصلابة، ولكن الإضافة الدقيقة للعناصر المعدنية الأخرى والتلاعب التالي في البنية البلورية للفولاذ، أو البنية المجهرية، هي التي تطلق العنان لإمكاناته الكاملة.

أثناء التصنيع، يتم استخدام المعالجة الحرارية لتحويل البنية الداخلية للصلب. ويتمثل الهدف من ذلك في تكوين بنية مجهرية دقيقة الحبيبات وعالية الإجهاد، تتكون في الغالب من المارتينسيت المقسّى. والمارتينسيت هو طور شديد الصلابة والقوة ولكنه هش يتشكل عن طريق التبريد السريع للصلب من درجة حرارة عالية. تعمل عملية التقسية التالية على تخفيف الضغوط الداخلية جزئياً وصقل الهيكل، مما يؤدي إلى مبادلة قدر ضئيل من الصلابة مقابل زيادة كبيرة في الصلابة والمرونة. وينتج عن ذلك أفضل توازن للخصائص المطلوبة لمثبتات موثوقة. إن فهم دور كل عنصر معدني هو المفتاح لتقدير كيفية تحقيق هذا التوازن.

المكونات الرئيسية

العناصر المعدنية هي "توابل" صناعة الصلب. يمكن للإضافات الصغيرة والدقيقة أن يكون لها تأثيرات كبيرة على استجابة المادة للمعالجة الحرارية وخصائص التشغيل النهائية.

- الكربون (C): بصفته عامل التصلب الأساسي في الفولاذ، يزيد الكربون من الصلابة وقوة الشد كلما زاد تركيزه. ومع ذلك، فإن ذلك له ثمن. يقلل محتوى الكربون المرتفع أيضًا من المرونة والمتانة، مما يجعل الفولاذ أكثر هشاشة. وبالتالي فإن مستوى الكربون في الفولاذ عالي القوة في الفولاذ عالي الصلابة هو حل وسط يتم التحكم فيه بعناية.

- المنغنيز (Mn): المنجنيز عنصر حيوي يخدم غرضين رئيسيين. فهو يعمل كمنظف أثناء إنتاج الصلب، حيث يزيل الشوائب. والأهم من ذلك بالنسبة للأداء، فهو يحسن بشكل كبير من قابلية التصلب - أي قدرة الفولاذ على تشكيل المارتينسيت عند التبريد. وهذا يسمح بالتصلب الفعال من خلال الأجزاء الأكثر سمكًا من البرغي.

- الكروم (Cr): الكروم سبيكة متعددة الاستخدامات تعزز الصلابة ومقاومة التآكل والمتانة. وتتمثل مساهمته الأكثر شهرة في زيادة مقاومة التآكل، على الرغم من أن الكميات المستخدمة في معظم أنواع الفولاذ عالي القوة ذات البراغي توفر حماية خفيفة فقط مقارنة بالفولاذ المقاوم للصدأ الحقيقي.

- الموليبدينوم (Mo): يُعد الموليبدينوم عامل سبائك قوي، خاصةً في التطبيقات التي تنطوي على درجات حرارة عالية. فهو يعزز القوة في درجات الحرارة العالية (مقاومة الزحف) ويحسّن الصلابة بشكل كبير. والأهم من ذلك، أنه يساعد أيضًا على تقليل هشاشة المزاج، وهي ظاهرة يمكن أن يصبح فيها الفولاذ هشًا إذا تم الاحتفاظ به في نطاق درجة حرارة معينة لفترة طويلة جدًا.

- البورون (B): يُستخدم البورون بكميات صغيرة جدًا ومضبوطة بدقة (غالبًا ما تكون أجزاء في المليون)، وهو أكثر عوامل التصلب فعالية. فهو يزيد بشكل كبير من صلابة الفولاذ منخفض ومتوسط الكربون. وهذا يسمح للمهندسين بتحقيق مستويات قوة عالية جدًا مع انخفاض محتوى الكربون، مما يحسن بدوره من صلابة المادة وقابليتها للحام.

| عنصر السبائك | الوظيفة (الوظائف) الأساسية | التأثير على الأداء |

| الكربون (C) | يزيد من الصلابة وقوة الشد | العنصر الأساسي لتحقيق القوة؛ يتطلب التحكم الدقيق لتجنب الهشاشة. |

| المنجنيز (Mn) | يحسن الصلابة وينظف الفولاذ | يسمح بالتصلب الفعال في المقاطع السميكة ويعزز الصلابة. |

| الكروم (Cr) | يزيد من الصلابة، ومقاومة التآكل، ومقاومة التآكل، ومقاومة التآكل | حاسم للأداء في البيئات التي تتسبب في التآكل المعتدل ولتطبيقات التآكل. |

| الموليبدينوم (Mo) | تعزيز القوة والمتانة والصلابة والصلابة في درجات الحرارة العالية | يمنع هشاشة المزاج ويحافظ على القوة في الخدمة في درجات الحرارة العالية. |

| البورون (B) | زيادة الصلابة في الفولاذ منخفض الكربون بشكل كبير | يسمح بتحقيق قوة عالية مع محتوى أقل من الكربون، مما يحسن من قابلية اللحام والمتانة. |

من الفولاذ الخام إلى البرغي النهائي

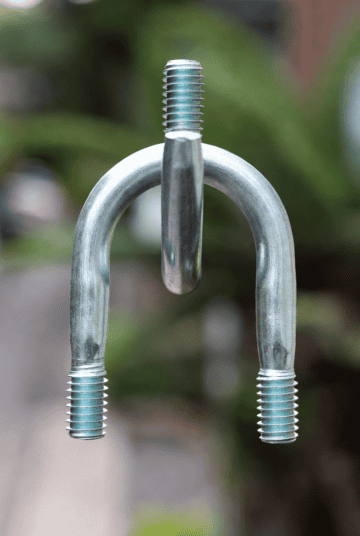

إن الرحلة من قضيب فولاذي خام إلى مسمار نهائي عالي القوة هي عملية متعددة المراحل حيث يرتبط التشكيل الميكانيكي والمعالجة الحرارية ارتباطًا وثيقًا. تبدأ العملية عادةً بسحب قضبان أسلاك الفولاذ على الساخن أو البارد إلى القطر الدقيق المطلوب للمسمار. تزيد عملية الشغل على البارد هذه في حد ذاتها من قوة الفولاذ وتحسّن من تشطيب سطحه. يتم بعد ذلك تغذية السلك في الماكينات التي تقوم بتشكيل الرأس، وبالنسبة للعديد من أنواع البراغي يتم لف الخيوط. دحرجة الخيط أفضل من قطع الخيط، حيث إنه يعمل على تبريد المادة ويخلق تدفق حبيبات يتبع شكل الخيط، مما ينتج عنه قفل تثبيت أقوى وأكثر مقاومة للتعب.

على الرغم من أهمية التشكيل، إلا أن المرحلة الأكثر أهمية في تطوير الخصائص النهائية لصلب البراغي عالي القوة هي دورة المعالجة الحرارية. بالنسبة للغالبية العظمى من هذه المثبتات، يتضمن ذلك عملية تبريد وتلطيف يتم التحكم فيها بدقة. هذه المعالجة الحرارية المكونة من خطوتين هي ما يحول البنية المجهرية الداخلية للصلب لتقديم الخصائص الميكانيكية المحددة.

عملية الجودة والتقييم

دورة التسقية والتقسية هي حجر الزاوية في إنتاج الصلب عالي القوة. يجب تنفيذ كل خطوة بدقة لضمان أن المنتج النهائي يلبي مواصفات التصميم الخاصة به من حيث القوة والمرونة والصلابة.

- الخطوة 1: التسخين (التقسية): يتم تسخين البراغي المشكّلة في فرن في الغلاف الجوي يتم التحكم فيه إلى درجة حرارة محددة، تتراوح عادةً بين 830-860 درجة مئوية (1525-1580 درجة فهرنهايت). عند درجة الحرارة هذه، يتحول التركيب البلوري للصلب إلى طور يسمى الأوستينيت، والذي يحتوي على شبكة مكعبة متمركزة على الوجه. هذا التركيب قادر على إذابة الكربون وعناصر السبائك في محلول صلب، مما يؤدي إلى "إعادة ضبط" البنية المجهرية للصلب وإعداده للخطوة الحرجة التالية.

- الخطوة 2: التبريد بالتبريد: بعد التسخين مباشرة، يتم تبريد البراغي بسرعة عن طريق غمسها في وسط تبريد، مثل الزيت أو الماء أو بوليمر متخصص. هذا التبريد السريع، أو التبريد بالتبريد، لا يسمح لبنية الأوستينيت بوقت كافٍ للتحول مرة أخرى إلى المراحل الأكثر ليونة الموجودة في الفولاذ غير المعالج. وبدلاً من ذلك، فإنه يجبر ذرات الكربون على أن تصبح محصورة داخل شبكة بلورية رباعية الزوايا شديدة التوتر متمركزة في الجسم تعرف باسم المارتنسيت. هذا التركيب المارتنسيتي شديد الصلابة والقوة ولكنه هش للغاية أيضًا. وتُعد سرعة التبريد أمرًا بالغ الأهمية؛ فإذا كانت بطيئة للغاية، لن تتحقق البنية المارتنسيتية بالكامل، ولن تتحقق القوة المطلوبة.

- الخطوة 3: التقسية: تتمثل الخطوة الأخيرة في تقسية البراغي الهشة والمسلوقة. ينطوي ذلك على إعادة تسخينها إلى درجة حرارة منخفضة - في أي مكان من 350 درجة مئوية إلى 650 درجة مئوية (660 درجة فهرنهايت إلى 1200 درجة فهرنهايت)، اعتمادًا على الدرجة المحددة والخصائص النهائية المطلوبة. يتم الاحتفاظ بالمسامير في درجة الحرارة هذه لفترة زمنية محددة، ثم تُترك لتبرد. تقلل هذه العملية من الصلابة الشديدة والضغوط الداخلية للمارتينسيت، مما يسمح للبنية المجهرية بالاسترخاء وتشكيل جزيئات كربيد دقيقة. يزيد التقسية من مرونة المادة وصلابتها بشكل كبير. تعتبر درجة حرارة التقسية هي متغير التحكم الأساسي؛ حيث تؤدي درجة حرارة التقسية المنخفضة إلى قوة وصلابة أعلى، بينما تؤدي درجة حرارة التقسية الأعلى إلى قوة أقل ولكن مرونة وصلابة أكبر.

بعد المعالجة الحرارية، قد تخضع البراغي إلى المعالجات السطحية مثل الطلاء بالفوسفات لمقاومة التآكل والتشحيم، أو الجلفنة من أجل حماية أقوى من التآكل. ومع ذلك، فإن الطلاء بالكهرباء أو الجلفنة بالغمس الساخن للفولاذ عالي القوة (عادةً ما يزيد عن 150 كيلو باسكال من قوة الشد) يؤدي إلى خطر كبير من هشاشة الهيدروجين، وهو نمط فشل كارثي يتطلب إدارة دقيقة من خلال اختيار المواد وعمليات الخبز بعد الطلاء.

فهم المعايير

لضمان الموثوقية والتوافق، تخضع البراغي عالية القوة ومواد مصدرها لمعايير دولية صارمة. وتنشر منظمات مثل ASTM الدولية والمنظمة الدولية للتوحيد القياسي (ISO) واللجنة الأوروبية للتوحيد القياسي (EN) مواصفات تفصيلية تحدد التركيب الكيميائي والخصائص الميكانيكية والأبعاد ومتطلبات الاختبار. هذه المعايير هي لغة الهندسة، مما يسمح للمصمم في بلد ما بتحديد مسمار يمكن الحصول عليه بشكل موثوق من مصنع في بلد آخر.

بالنسبة للمشاريع في أمريكا الشمالية، تعتبر المواصفات القياسية التي تنشرها ASTM الدولية هي الأكثر شيوعًا. وتوفر هذه المواصفات خارطة طريق واضحة للمهندسين وأخصائيي المشتريات، حيث تحدد درجات مميزة من البراغي لتطبيقات محددة، بدءًا من الآلات ذات الأغراض العامة إلى الوصلات الفولاذية الإنشائية الحرجة وأوعية الضغط ذات درجة الحرارة العالية. يعد فهم الاختلافات الرئيسية بين هذه الدرجات الشائعة أمرًا أساسيًا للاختيار الصحيح للبراغي.

درجات ASTM الشائعة

يغطي كل معيار من معايير ASTM مجموعة محددة من المتطلبات المصممة خصيصًا لبيئة خدمة معينة. تحدد درجة البرغي مستوى قوته ونوع الفولاذ المستخدم.

- A325 / A325: هذه واحدة من أكثر المواصفات شيوعًا للبراغي الإنشائية المستخدمة في الوصلات الفولاذية في المباني والجسور. وهي مصنوعة من فولاذ متوسط الكربون. المواصفة القياسية F3125 هي مجموعة حديثة تدمج الآن مواصفات A325 و A490 و F1852 و F2280 القديمة في وثيقة واحدة شاملة. البراغي من النوع 1 A325 هي خط الأساس للتطبيقات الإنشائية.

- astm F3125 / A490: توفر براغي A490 من النوع 1 A490، التي تندرج أيضًا تحت مظلة F3125، قوة شد وإنتاجية أعلى بكثير من براغي A325. وهي مصنوعة من سبيكة فولاذ مروي ومخفف ومخصصة للوصلات الهيكلية عالية الإجهاد حيث يتطلب الأمر قدرة أكبر على التحميل المسبق والقص. نظرًا لقوتها العالية، فهي أكثر عرضة للهشاشة الهيدروجينية ولا يجب جلفنتها.

- ASTM A193 من الدرجة B7: تغطي هذه المواصفة مواد التثبيت بالبراغي المصنوعة من سبائك الصلب للخدمة في درجات الحرارة العالية والضغط العالي. تُعد مسامير ومسامير B7 شائعة في صناعات النفط والغاز والبتروكيماويات لتثبيت الشفاه على أوعية الضغط والصمامات وخطوط الأنابيب. هذه المادة عبارة عن سبيكة فولاذ من سبائك الكروم والموليبدينوم (Cr-Mo)، يتم إخمادها وتلطيفها لتوفير قوة ممتازة في كل من درجات حرارة الغرفة ودرجات الحرارة العالية.

- ASTM A354 درجة BD: تغطي هذه المواصفة القياسية مسامير سبائك الصلب المروي والمقوى والمسامير وغيرها من أدوات التثبيت الملولبة خارجيًا حتى قطر 4 بوصات. الدرجة BD هي درجة عالية القوة ذات خصائص ميكانيكية مشابهة جدًا للدرجة ASTM A490. ومع ذلك، فهي مواصفات عامة الأغراض، مما يجعلها مناسبة لمجموعة واسعة من التطبيقات في الآلات والسيارات والتثبيت والتشييد العام حيث لا تنطبق القواعد المحددة لأعمال الصلب الإنشائية.

| الصف | نطاق الحجم الاسمي (بالبوصة) | قوة الشد، الحد الأدنى (ksi) | قوة الخضوع، الحد الأدنى (كسي) | نوع المادة الأساسية | التطبيقات الشائعة |

| F3125 / A325 | 1/2 إلى 1-1/2 | 120 (للمقاسات ≤ 1″)، 105 (للمقاسات > 1″) | 92 (للأحجام ≤ 1″)، 81 (للأحجام > 1″) | الفولاذ الكربوني المتوسط | الوصلات الفولاذية الهيكلية والمباني والجسور |

| F3125 / A490 | 1/2 إلى 1-1/2 | 150 – 173 | 130 | سبائك الصلب | الوصلات الهيكلية عالية الإجهاد، والتطبيقات التي تتطلب تحميلًا مسبقًا أعلى |

| A193 / B7 | حتى 2-1/2 | 125 | 105 | سبائك الصلب المصنوعة من الكروم والموليبدينوم | الشفاه ذات درجة الحرارة العالية/الضغط العالي، وأوعية الضغط، والصمامات |

| A354 / BD | 1/4 إلى 4/1 | 150 | 130 | سبائك الفولاذ المروي والمقوى | الهندسة العامة، والآلات، ومسامير التثبيت، والسيارات |

فهم الخواص الميكانيكية

على الرغم من أن الحد الأدنى لقوة الشد هو الرقم الرئيسي لأي مسمار عالي القوة، إلا أن التحليل الهندسي الذكي يتطلب فهمًا أكثر اكتمالاً لسلوك المادة. يمكن أن يؤدي الاعتماد على نقطة بيانات واحدة إلى اختيار مادة سيئة أو حتى غير آمنة. يأخذ التصميم الموثوق به حقًا في الاعتبار مجموعة من الخصائص الميكانيكية التي تحدد مجتمعة كيفية أداء البرغي في ظل ظروف الخدمة المعقدة في العالم الحقيقي. إن أداء فولاذ المسامير الفولاذية عالية القوة لا يتم سرده من خلال قوته فحسب، بل من خلال مرونته وصلابته ومقاومته للإجهاد.

مقاييس الأداء الحرجة

- قوة الخضوع: بالنسبة لمهندس التصميم، غالبًا ما تكون مقاومة الخضوع هي الخاصية الأكثر أهمية. وهي تمثل الإجهاد الذي تبدأ عنده المادة في التشوه بشكل دائم. بينما تحدد قوة الشد أقصى حمل يمكن أن يتحمله البرغي قبل أن ينكسر، فإن أي حمل يتجاوز قوة الخضوع سيؤدي إلى تمدد دائم للبرغي، مما يؤدي إلى فقدان التحميل المسبق وتلف الوصلة. تعتمد حسابات التصميم دائمًا تقريبًا على قوة الخضوع مع تطبيق عامل أمان مناسب.

- المرونة والاستطالة: المرونة هي قدرة المادة على التشوه قبل أن تنكسر. وتقاس عادةً بـ "الاستطالة المئوية" و"الانخفاض المئوي للمساحة" في اختبار الشد. يمكن ثني المادة المرنة، مثل مشبك الورق، وتمديدها بشكل كبير قبل أن تنكسر. هذه الخاصية حيوية لعدة أسباب. فهي تسمح بالاستسلام الموضعي عند تركيزات الضغط، وإعادة توزيع الحمل ومنع الفشل المبكر. وعلاوة على ذلك، فإنه يوفر تحذيرًا واضحًا للحمل الزائد - حيث إن البرغي الممدود هو علامة واضحة على أن الوصلة قد تعرضت لقوى تتجاوز الحد التصميمي لها.

- المتانة (قوة التصادم): الصلابة هي قدرة المادة على امتصاص الطاقة ومقاومة الكسر، خاصةً تحت التحميل المفاجئ عالي المعدل (الصدمة). وهي تختلف عن القوة. يمكن أن تكون المادة قوية جدًا ولكنها هشة (مثل الزجاج)، أو يمكن أن تكون قوتها أقل ولكنها قوية جدًا (مثل الفولاذ الطري). بالنسبة للتطبيقات التي تنطوي على أحمال الصدمات أو التي تعمل في درجات حرارة منخفضة، تعتبر الصلابة من أهم الاهتمامات. ويتم قياسها بشكل أكثر شيوعًا باستخدام اختبار تشاربي V-notch للصدمات، والذي يحدد الطاقة التي تمتصها عينة قياسية عند ضربها ببندول.

- قوة التعب: تتعرض العديد من الوصلات المثبتة بمسامير لأحمال متكررة أو متغيرة، مثل تلك الموجودة في المحركات والآلات الاهتزازية والجسور تحت حركة المرور. في ظل هذه الظروف، يمكن أن يفشل البرغي عند مستوى إجهاد أقل بكثير من قوة الخضوع من خلال عملية تسمى التعب. قوة التعب، أو حد التحمل، هي أعلى إجهاد يمكن أن تتحمله المادة لعدد معين من الدورات دون أن تفشل. وتتأثر هذه الخاصية بشكل كبير بالصقل السطحي للبراغي وطريقة تصنيع اللولب (اللولب الملفوف أفضل)، والأهم من ذلك، حجم التحميل المسبق المثبت.

- الصلابة: الصلابة هي مقياس لمقاومة المادة للتشوه البلاستيكي الموضعي، مثل الخدش أو الانبعاج. ويتم قياسها عادةً باستخدام اختبارات روكويل أو برينل. بالنسبة لفولاذ المسامير، تعتبر الصلابة مؤشرًا ممتازًا لقوة الشد ومقاومة التآكل. وغالبًا ما يتم استخدامه كفحص لمراقبة الجودة أثناء التصنيع لأن اختبار الصلابة سريعة وغير مدمرة وتوفر مؤشرًا موثوقًا لما إذا كانت عملية المعالجة الحرارية ناجحة أم لا.

عند تعطل البراغي

معظم أعطال أدوات التثبيت ليست نتيجة "مسمار سيء" أو عيب في المادة نفسها. من وجهة نظر محلل الأعطال من ذوي الخبرة، فإن السبب الجذري دائمًا ما يكون عدم التوافق بين قدرات البرغي ومتطلبات تطبيقه. يمكن أن ينبع هذا من حسابات التصميم غير الصحيحة، أو اختيار المواد غير المناسبة لبيئة الخدمة، أو، في أغلب الأحيان، إجراءات التركيب غير الصحيحة. يعد فهم التواقيع المعدنية المميزة لأنماط الفشل الشائعة مهارة تشخيصية بالغة الأهمية لأي مهندس أو فني مسؤول عن سلامة الوصلات المثبتة بمسامير. من خلال فحص سطح الكسر وفهم الآلية، يمكننا تحديد السبب الجذري وتنفيذ إجراءات تصحيحية فعالة.

تشخيص السبب

يترك كل نمط فشل وراءه أدلة مميزة على سطح الكسر. يمكن أن يكشف الفحص البصري الدقيق، بمساعدة المجهر في كثير من الأحيان، عن تاريخ حدث الكسر.

- فشل الحمل الزائد: هذا هو وضع الفشل الأكثر وضوحًا، ويحدث عندما يتجاوز حدث تحميل واحد قوة الشد القصوى للمسمار. يتميز التحميل الزائد المرن بتشوه بلاستيكي كبير، بما في ذلك "النخر" (انخفاض موضعي في القطر) وسطح الكسر "الكوب والمخروط" الذي يبدو باهتًا وليفيًا. وعلى النقيض من ذلك، يُظهر الحمل الزائد الهش تشوهًا بلاستيكيًا ضئيلًا أو معدومًا وسطح كسر حبيبي لامع. يشير هذا عادةً إلى مادة ذات صلابة غير كافية أو عيب موجود مسبقًا.

- فشل الإجهاد: وهو فشل تدريجي ناتج عن التحميل المتكرر. يبدأ بتشقق مجهري، عادةً ما يكون في نقطة تركيز إجهاد عالٍ مثل جذر اللولب. مع كل دورة تحميل، ينمو الشق ببطء عبر المقطع العرضي للبراغي. تترك مرحلة النمو هذه وراءها "علامات شاطئية" مميزة على سطح الكسر، وهي عبارة عن تموجات متحدة المركز قادمة من منشأ الشق. في نهاية المطاف، يكون المقطع العرضي المتبقي صغيرًا جدًا لتحمل الحمل، ويفشل في كسر نهائي مفاجئ زائد الحمل. إن وجود العلامات الشاطئية هو العلامة القاطعة لفشل الكلل، وغالباً ما يكون سببها عدم كفاية التحميل المسبق (شد البرغي).

- هشاشة الهيدروجين: هذا هو نمط فشل مخادع وخطير بشكل خاص، حيث يمكن أن يحدث دون سابق إنذار وعند مستويات إجهاد أقل بكثير من قوة خضوع المادة. ويحدث ذلك عندما يدخل الهيدروجين الذري في الشبكة البلورية للصلب، عادةً أثناء التصنيع (مثل التخليل الحمضي أو الطلاء الكهربائي) أو من التآكل أثناء الخدمة. وتقلل ذرات الهيدروجين من مرونة الفولاذ، مما يؤدي إلى كسر كارثي هش. قد يتأخر الكسر، حيث يحدث بعد ساعات أو حتى أيام من إحكام ربط البرغي. يكون الفولاذ عالي القوة (أعلى من 150 كيلو باسكال) عرضة للكسر بشكل خاص. عادةً ما يكون سطح الكسر عادةً بين الحبيبات مما يعني أن الكسر يتبع حدود حبيبات الفولاذ.

- التشقق الناتج عن التآكل الإجهادي (SCC): التشقق الإجهادي الإجهادي (SCC) هو فشل هش ينتج عن عمل ثلاثة عوامل مجتمعة: مادة معرضة للتآكل، وإجهاد شد مستمر (من التحميل المسبق)، وبيئة تآكل محددة. إذا تمت إزالة أي عامل من هذه العوامل الثلاثة، فلن يحدث التآكل الجزئي. تكون السبائك المختلفة عرضة لبيئات مختلفة؛ على سبيل المثال، تكون بعض أنواع الفولاذ المقاوم للصدأ عرضة للتكلس الجليدي المجلفن في البيئات الغنية بالكلوريد. يظهر الفشل كشبكة من الشقوق الدقيقة المتفرعة التي يمكن أن تكون إما بين الحبيبات أو عبر الحبيبات (تقطع خلال الحبيبات).

| وضع الفشل | الإشارات البصرية النموذجية | السبب/الحالة المعدنية المحتملة | استراتيجيات الوقاية |

| حمولة زائدة مرنة | نخر كبير للأسفل، سطح كسر "كوب ومخروطي"، مظهر باهت/ليفي. | تجاوز الحمل قوة الشد القصوى للمادة. | اختيار حجم/درجة البرغي الصحيح؛ التحقق من حسابات الحمولة. |

| الإرهاق | "العلامات الشاطئية" التي تنشأ من نقطة بدء الشق؛ وغالباً ما تكون منطقة الكسر النهائية خشنة. | تحميل متكرر فوق حد التحمل للمادة، وغالبًا ما يكون ذلك بسبب عدم كفاية التحميل المسبق. | ضمان التحميل المسبق (عزم الدوران) المناسب؛ التصميم لتقليل تركيزات الإجهاد. |

| هشاشة الهيدروجين | كسر هش بين الخلايا الحبيبية مع عدم وجود نخر؛ قد يتأخر الفشل بعد الشد. | إدخال الهيدروجين أثناء التصنيع (الطلاء) أو الخدمة (التآكل). | استخدام براغي مخبوزة بعد الطلاء؛ اختيار الطلاء المناسب؛ التحكم في البيئة. |

| التشقق الناتج عن التآكل الإجهادي (SCCC) | شقوق هشّة أو متفرعة أو بين الحبيبات أو عبر الحبيبات. | إجهاد الشد المستمر في بيئة تآكل محددة (مثل الكلوريدات والكبريتيدات). | اختر مادة مقاومة للبيئة المحددة؛ استخدم الطلاءات الواقية؛ قلل من الإجهادات المتبقية. |

اختيار الفولاذ المناسب

إن اختيار فولاذ البرغي عالي القوة المناسب ليس بحثًا عن المادة "الأفضل"، ولكنه عملية منهجية لتحديد المادة "المناسبة" لتطبيق معين. نادرًا ما يكون البرغي الأقوى والأكثر صلابة هو الخيار الأفضل. الاختيار الأمثل هو حل وسط مدروس بعناية يوازن بين الخواص الميكانيكية والمقاومة البيئية والتكلفة مقابل المتطلبات المحددة للتصميم. من خلال الجمع بين المعلومات الفنية التي تمت تغطيتها، يمكن لمهندس التصميم التعامل مع هذه المهمة بإطار عمل واضح ومنطقي يعتمد على طرح الأسئلة الصحيحة.

معايير الاختيار الرئيسية

يمكن تنظيم هذه العملية على شكل سلسلة من الأسئلة المهمة. ستوجهك الإجابة على هذه الأسئلة إلى أنسب درجة ومواصفات المواد.

- ما هي متطلبات الحمل؟ الخطوة الأولى هي توصيف القوى التي يجب أن يتحملها البرغي. هل الحمل ثابت (ثابت) أم ديناميكي (متغير)؟ ما هو حجم أحمال الشد والقص؟ سيوجه هذا التحليل الحد الأدنى المطلوب من قوة الخضوع وقوة الشد، وبالنسبة للتطبيقات الديناميكية، أهمية قوة التعب.

- ما هي بيئة التشغيل؟ تلعب بيئة الخدمة دورًا حاسمًا. ما هو نطاق درجات حرارة التشغيل؟ هل سيتعرض البرغي للرطوبة أو الملح أو المواد الكيميائية الصناعية أو غيرها من العوامل المسببة للتآكل؟ ستحدد الإجابات الحاجة إلى سبائك معينة توفر قوة في درجات الحرارة العالية (مثل الموليبدينوم) أو ضرورة الطلاءات الواقية. في البيئات شديدة التآكل، قد تكون هناك حاجة إلى مادة أقل قوة ولكن أكثر مقاومة مثل الفولاذ المقاوم للصدأ.

- ما هي عواقب الفشل؟ هل الوصلة المثبتة بمسامير جزء من نظام حرج حيث يكون الفشل كارثيًا، أم أنها تطبيق غير حرج؟ بالنسبة للمفاصل الحرجة، تصبح الخصائص مثل الصلابة والمرونة أكثر أهمية. تكون المادة الأكثر صلابة أكثر مقاومة للكسر من أحمال الصدمات غير المتوقعة، ويمكن أن توفر المادة المرنة تحذيرًا مرئيًا بالحمل الزائد قبل حدوث فشل كامل. يؤثر هذا التحليل بشكل مباشر على عوامل الأمان المطلوبة في التصميم.

- هل هناك أي قيود على التصنيع أو التجميع؟ يجب مراعاة دورة الحياة بأكملها. هل سيتم تغليف البرغي أو طلاؤه؟ إذا كان الأمر كذلك، يجب معالجة خطر هشاشة الهيدروجين، ربما عن طريق اختيار فولاذ أقل قوة أو تحديد عملية خبز بعد الطلاء. هل هناك أي تحديات تجميع غير عادية قد تؤدي إلى تحميل خارج المحور؟

- ما هي الرموز والمعايير الحاكمة؟ تخضع العديد من التطبيقات، لا سيما في الهندسة الإنشائية والفضاء وتصميم أوعية الضغط، لقوانين صارمة في الصناعة (على سبيل المثال، AISC للصلب الإنشائي، ASME لأوعية الضغط). غالبًا ما تتطلب هذه الرموز استخدام درجات مسامير ASTM أو ISO محددة وتصف إجراءات التركيب والفحص. الامتثال ليس اختياريًا.

الخاتمة: القوة الخفية

إن الأداء الرائع للمسامير عالية القوة ليس من قبيل المصادفة؛ بل هو نتيجة مباشرة ومتوقعة لعلم المواد الأساسي الذي يقوم عليه. ترتكز سلامة مشاريعنا الهندسية الأكثر طموحًا على التحكم الدقيق في التركيب الكيميائي والتاريخ الحراري لصلب البراغي عالي القوة الذي يتم تصنيع هذه البراغي منه. السحابات مصنوعة. تُعد الرحلة من سبيكة مصممة بعناية إلى مسمار نهائي معالج بالحرارة شهادة على قوة علم المعادن التطبيقي.

لقد رأينا كيف يمكن لبضعة أعشار من عشرة في المائة من الكربون أن توفر قوة أساسية، وكيف يمكن لكميات ضئيلة من البورون أن تعزز الصلابة بشكل كبير، وكيف يمكن للموليبدينوم أن يحافظ على تلك القوة في درجات الحرارة العالية. لقد قمنا بتفصيل عملية التبريد والتلطيف الحرجة، وهي المعالجة الحرارية التي تخلق البنية المجهرية المارتنسيتية القوية والضرورية للأداء. من خلال فهم لغة المعايير مثل ASTM F3125 و A193، يمكننا تحديد المواد اللازمة لأي تطبيق بثقة.

وفي نهاية المطاف، فإن التقدير العميق للمجموعة الكاملة من خصائص المواد - قوة الإنتاجية والمرونة والمتانة ومقاومة التعب - هو ما يفصل بين التصميم الملائم والهندسة الاستثنائية. إن التعرف على العلامات الدالة على أنماط الفشل مثل التعب والهشاشة الهيدروجينية يحولنا من حل المشاكل التفاعلية إلى مصممين استباقيين. إن الفهم الشامل للفولاذ عالي القوة ذو البراغي هو الخطوة الأولى والأكثر أهمية نحو بناء آلات وهياكل أكثر أمانًا وموثوقية ومتانة في المستقبل.

- منظمة ASTM الدولية - اختبار المواد والمعايير https://www.astm.org/

- SAE الدولية - معايير هندسة السيارات والفضاء SAE الدولية - معايير هندسة السيارات والفضاء https://www.sae.org/

- ASME - الجمعية الأمريكية للمهندسين الميكانيكيين https://www.asme.org/

- معهد السحابات الصناعية (IFI) https://www.indfast.org/

- NIST - المعهد الوطني للمعايير والتكنولوجيا https://www.nist.gov/

- ISO - المنظمة الدولية للتوحيد القياسي https://www.iso.org/

- منظمة ASM الدولية - جمعية معلومات المواد https://www.asminternational.org/

- ANSI - المعهد الوطني الأمريكي للمعايير الأمريكية https://www.ansi.org/

- علوم وهندسة المواد - ScienceDirect Topics https://www.sciencedirect.com/topics/materials-science

- جمعية المعادن والفلزات والمواد (TMS) https://www.tms.org/