The Engineer’s Guide to Track Maintenance: Understanding the Basics

Keeping railway tracks in good condition is essential for national economies and public safety. While it might look like simple routine work, effective track maintenance is actually a complex engineering field. It uses knowledge from materials science, soil engineering, and mechanical engineering to handle the huge forces created where train wheels meet the rails. This guide goes beyond just listing tasks to give you a clear understanding of the engineering and physics principles that keep tracks healthy. We will look at the track as a moving system, study the forces that cause damage, explain why certain repairs are needed, and explore how maintenance strategies have changed over time.

This analysis will help you understand:

- What each track part does from an engineering perspective.

- The basic physical and material science reasons why tracks break down.

- Why key maintenance procedures like tamping, grinding, and ballast cleaning are necessary.

- How different modern maintenance approaches compare, from preventive to predictive.

- New technologies that are changing the future of track maintenance.

The Engineered Foundation

To understand maintenance, you must first see the track not as a simple path, but as a complex engineering system carefully designed to manage and spread out energy. Each part has a specific job in absorbing and transferring huge moving loads from a train safely into the ground. Understanding why each part is designed the way it is helps you understand how it fails and why we maintain it the way we do.

The Rail Element

The rail does two main jobs: it guides the train wheels using the wheel flange and supports the massive up-and-down, side-to-side, and forward-and-backward forces from train traffic. The rail shape, with its specific head design and cant (inward slope), is engineered to optimize where and how big the wheel-rail contact area is. This reduces stress and wear. The material itself comes from advanced metal-making. Modern rails are typically made from high-carbon, wear-resistant steels, such as R260 and R350HT grades under European (EN 13674) or similar AREMA standards. These metal mixtures are designed to resist repeated stress cycles and have a tensile strength often over 880 MPa to handle the millions of load cycles they experience.

The Sleeper System

The sleeper, or tie, is the crosswise piece that does two important things: it rigidly keeps the track gauge (the distance between rails) and spreads the concentrated load from the rail foot across a wider area of the ballast. This load spreading is a core soil engineering principle, reducing the pressure on the ballast to prevent it from being crushed or pushed aside. Choosing sleeper material involves engineering trade-offs. Pre-stressed concrete offers superior strength under compression, a long service life, and significant weight, which helps overall track stability. Hardwood provides excellent flexibility and natural vibration dampening, though with a shorter lifespan. Steel and composite sleepers are used in specific situations, valued for their light weight in hard-to-reach areas or their resistance to environmental factors like insect damage.

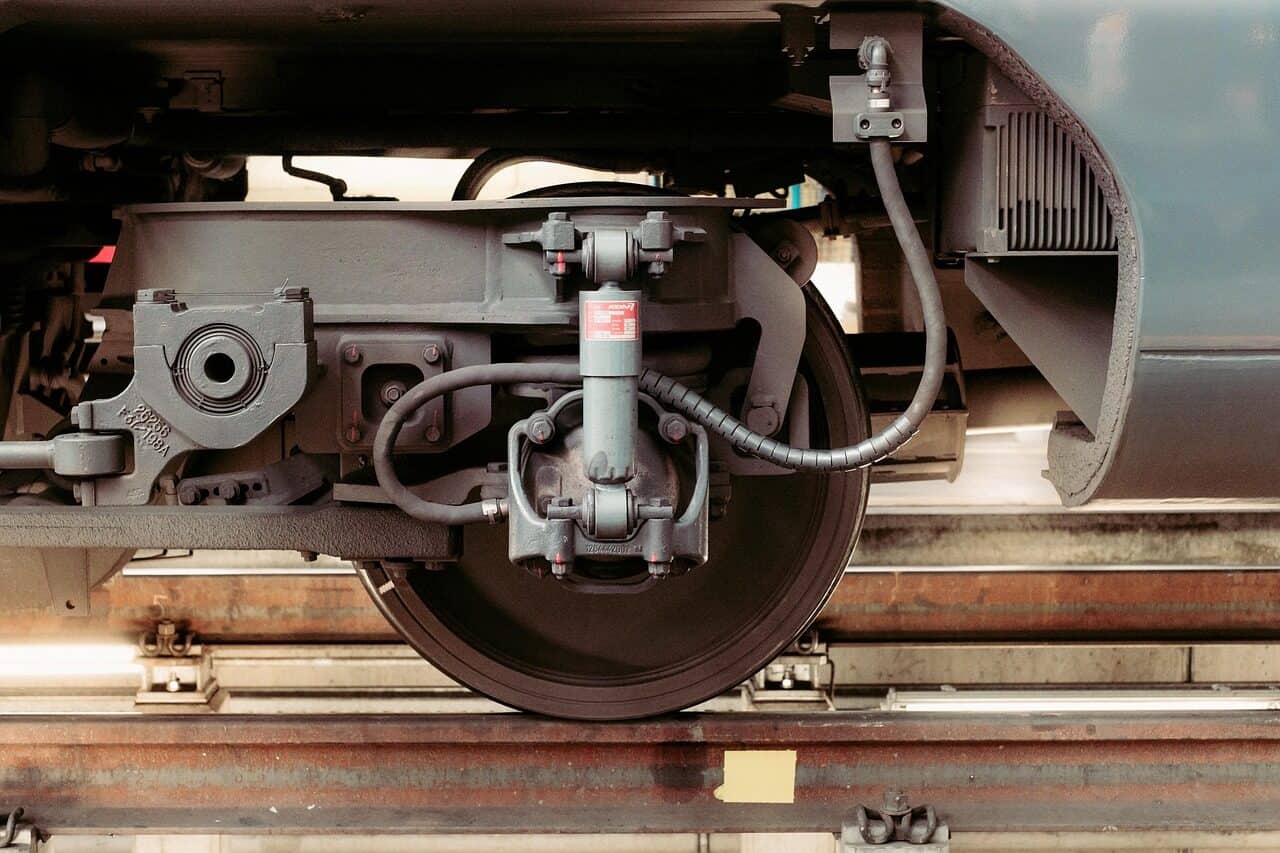

The Fastening System

The fastening system is the critical link that secures the rail to the sleeper. Its jobs go beyond simple attachment. It must provide a consistent clamping force to resist lengthwise rail movement, known as rail creep, which is caused by temperature expansion and braking or acceleration forces. In track-circuited areas, it must also provide electrical insulation to separate the rails from each other and from the ground. Modern elastic fastening systems, like the Pandrol e-Clip or Vossloh systems, are designed to provide a specific, engineered toe load. Their flexibility is crucial, allowing for tiny vertical rail movements under load without losing their clamping strength, thereby absorbing vibrations and reducing shock transfer into the sleeper and ballast.

The Ballast and Subgrade

The ballast layer and the underlying subgrade form the track’s flexible foundation. The ballast—a layer of crushed, hard, angular stone—performs several engineering functions at the same time. It provides a medium for precise track geometry correction, helps rapid drainage of water away from the track structure, and resists side-to-side, up-and-down, and lengthwise forces through friction between particles. The angular shape of the stones is crucial for creating interlock, which provides this frictional resistance. The void ratio, or the amount of empty space between stones, is critical for drainage. The ballast depth is calculated to distribute the pressure from the sleepers down to a level that the subgrade—the native soil or prepared foundation layer—can support without permanent bending or foundation failure.

The Science of Degradation

Track does not simply “wear out.” It gets worse through a series of predictable, interacting physical processes. Understanding these mechanisms at a material science and physics level is essential for moving from fixing problems after they happen to preventing them before they occur. Degradation results from repeated loading, environmental exposure, and material response.

Mechanical Wear Mechanisms

The most obvious form of degradation is mechanical wear where the wheel meets the rail. This happens mainly through two ways. Adhesive wear happens at a microscopic level, where the huge pressure in the contact area causes tiny welds to form and then immediately break as the wheel rolls, pulling away tiny pieces of material. Abrasive wear is the scraping action caused by hard particles (like sand or wheel-flange material) trapped between the wheel and rail.

A more hidden mechanism is Rolling Contact Fatigue (RCF). The repeated contact stresses from each passing wheel, which can exceed 1,500 MPa, cause fatigue in the steel. This is like bending a paperclip back and forth until it breaks. This process starts micro-cracks, typically just below the surface, which then grow. When these cracks reach the surface, they show up as critical defects like head checks (fine cracks on the gauge corner), squats (a dip in the running surface), and shelling (the breaking away of large metal flakes). For instance, on a heavy-haul freight line with 30-tonne axle loads, after several hundred million gross tonnes pass over a tight curve, the high stresses will inevitably start RCF micro-cracks in the gauge corner of the high rail. If not managed, these will grow and join together, leading to catastrophic rail failure.

Deformation and Geometry

Track geometry degradation is the loss of the track’s intended vertical and horizontal shape. It is a direct result of the dynamic, repeated loading on the ballast foundation. Each passing axle applies a force that causes tiny settlement and rearrangement of the ballast stones. Over time, these small movements add up, leading to uneven support. This results in measurable deviations in alignment (the straightness of the track), level or top (the vertical profile), and cant or superelevation (the banking on curves).

The rail itself can also deform. Under heavy loads, plastic flow can occur, where the metal of the rail head is slowly pushed and flattened, widening the running band. Rail corrugation, a wave-like pattern on the running surface, is a complex dynamic phenomenon resulting from a resonant “stick-slip” interaction between the wheel and rail at specific frequencies, leading to uneven wear, increased noise, and high-impact loading.

Material and Environment

The track foundation itself is subject to degradation. Ballast fouling is the process where the spaces between the angular stones become clogged with fine particles. These fines come from several sources: the breakdown and grinding of the ballast stones themselves (attrition), coal or iron ore dust from passing trains, and soil “pumping” up from a wet, unstable subgrade. As the spaces fill, the ballast loses its ability to drain water. This trapped water lubricates the stones, reducing friction between particles and dramatically speeding up geometry degradation. A fouled ballast bed behaves more like a solid mass than a flexible, free-draining layer. Corrosion is another significant factor, a chemical process that attacks steel rails and fastening components, particularly in humid, polluted, or salty environments like coastal areas or tunnels.

Table 1: Common Track Defects & Their Underlying Technical Cause

| اسم العيب | Technical Description | Primary Causal Principle |

| Head Checking | A series of fine, parallel cracks on the gauge corner of the rail head. | Rolling Contact Fatigue (RCF) from high cyclic wheel-rail contact stresses. |

| تلوث الصابورة | Clogging of ballast voids with fine particles (e.g., broken stone, coal dust, soil). | Particle attrition, subgrade pumping, and loss of inter-particle friction. |

| Track Buckling | Lateral, snake-like displacement of the track panel. | Unmanaged compressive thermal stress in Continuously Welded Rail (CWR). |

| Squat | A localized depression on the rail running surface, often with an associated crack. | High-impact dynamic loads combined with RCF initiation. |

| Misalignment | Deviation of the track’s horizontal straightness or curvature. | Non-uniform lateral support from the ballast and sleepers due to settlement. |

Principles of Intervention

Track maintenance tasks are not random; they are specific engineering interventions designed to counteract the degradation mechanisms detailed previously. Each activity has a clear technical goal, whether it is to restore geometry, recondition a material, or manage stress. Understanding the engineering principle behind each task is key to its proper application and effectiveness.

Restoring Track Geometry

Tamping and stoneblowing are the primary methods for correcting track geometry defects.

- Tamping: This is the most common method for restoring correct vertical and horizontal track geometry. A tamping machine uses vibrating tines that are inserted into the ballast on either side of a sleeper. The vibration temporarily makes the ballast flow like liquid, allowing the tines to squeeze together and pack stone directly under the sleeper base. This process lifts the track to a precise, pre-calculated position, correcting errors in level and alignment and re-establishing a uniform, compacted load-bearing surface beneath the sleeper.

- Stoneblowing: This is a more precise, less disruptive alternative to tamping. Instead of packing existing ballast, a stoneblowing machine uses high-pressure air to inject a measured quantity of new, smaller-sized stone into the spaces directly beneath the sleeper. This provides a very accurate lift and creates a durable stone “shim.” The primary technical advantage is that it does not disturb the existing, well-compacted ballast structure, often resulting in a longer-lasting geometry correction.

Managing the Interface

Rail grinding is a critical machining process that manages the condition of the wheel-rail interface itself. It is both a corrective and a preventive measure. The primary technical goals are:

- Removing RCF: Grinding removes the surface layer of the rail head, eliminating beginning head checks and other RCF-related micro-cracks before they can grow deeper into the rail and become major defects requiring rail replacement.

- Profile Correction: Grinding is used to reshape the rail head to a specific, engineered target profile. This target profile is designed to match the worn wheel profiles of the traffic using the line, optimizing the contact area to ensure proper vehicle steering on curves and reduce contact stresses. This proactive profile management is a cornerstone of modern maintenance, significantly reducing the rate of both rail and wheel wear.

- Corrugation Removal: The process effectively mills away the peaks of rail corrugations, restoring a smooth running surface and eliminating the high-frequency, high-impact dynamic loads that cause noise, vibration, and accelerated degradation of other track components.

Reconditioning the Foundation

When the ballast foundation itself has degraded, its primary functions must be restored through ballast cleaning or renewal.

- Ballast Cleaning: The principle behind this intervention is to restore the ballast’s drainage capacity and flexibility by removing the fine particles that cause fouling. A large on-track machine excavates the ballast from the shoulder and from beneath the sleepers. The excavated material is passed over a series of vibrating screens that separate the good, correctly sized ballast stone from the dirt, dust, and broken fragments. The cleaned stone is then put back into the track, and new stone is added to compensate for the removed material and to restore the correct ballast profile. This re-establishes the void ratio necessary for drainage and restores the friction between particles required for track stability.

Table 2: Maintenance Intervention vs. Technical Objective

| Maintenance Intervention | Primary Technical Objective | Degradation Counteracted |

| Tamping | Restore correct track geometry (level, alignment). | Differential ballast settlement, loss of uniform support. |

| Rail Grinding | Correct rail head profile and remove surface defects. | Rolling Contact Fatigue (RCF), plastic flow, corrugation. |

| Ballast Cleaning | Restore ballast drainage and elasticity. | Ballast fouling, particle breakdown, reduced friction. |

| Welding (Thermit/Flash-Butt) | Repair broken rails or create Continuously Welded Rail (CWR). | Rail fractures, joint-related impact loads. |

| Destressing | Re-establish the correct neutral temperature in CWR. | Risk of track buckling (compression) or pull-aparts (tension). |

The Evolution of Strategy

The philosophy guiding when and where to perform maintenance has evolved significantly, driven by technology, data analytics, and a deeper understanding of risk. The goal has shifted from simply fixing failures to proactively managing the rate of degradation, optimizing both safety and cost.

Reactive Maintenance

The “find and fix” model is the most basic strategy. Intervention occurs only after a component has failed or a defect has been identified that exceeds safety limits, often during a routine visual inspection or following an operational incident. This approach is characterized by its reliance on manual inspection and basic repair techniques. While it has the lowest upfront planning cost, it carries the highest long-term cost due to the high expense of emergency repairs, operational disruptions, and the significant risk of catastrophic failure. It is an inherently inefficient and high-risk way to manage a complex asset.

Preventive Maintenance

Preventive, or time-based, maintenance represents a significant strategic improvement. Interventions are scheduled at pre-determined intervals, which can be based on time (e.g., tamping every two years) or usage (e.g., grinding after every 50 million gross tonnes of traffic). These schedules are derived from statistical analysis of historical failure data, using methods like Weibull analysis to determine a component’s average service life or Mean Time Between Failures (MTBF). This strategy requires robust data logging of asset history and traffic, along with structured planning systems. It reduces the likelihood of in-service failures but can be inefficient, sometimes replacing components that still have significant remaining useful life or, conversely, failing to prevent a premature failure.

Predictive Maintenance

Predictive, or condition-based, maintenance is the current state-of-the-art. It embodies the principle of “maintain only when necessary.” Intervention is not driven by a fixed schedule but is triggered when frequently collected data indicates that a component’s condition is degrading towards a pre-defined performance or safety threshold. This data-driven approach relies heavily on advanced technology. Automated inspection vehicles, such as track geometry cars and ultrasonic test units, collect vast amounts of data on track condition. Wayside sensor systems detect real-time impacts from defective wheels or bearings. The core of this strategy lies in data analysis, where algorithms and machine learning models analyze trends to predict the future state of the track. For example, an algorithm might trigger a tamping intervention not when geometry reaches a limit, but when the rate of change of the standard deviation in track top level accelerates, indicating that the ballast is losing its stability and will soon require intervention.

Table 3: Technical Comparison of Maintenance Philosophies

| الميزة | Reactive Maintenance | Preventive Maintenance | Predictive Maintenance |

| Trigger for Action | Component failure or observed defect. | Fixed schedule (time or usage). | Condition data exceeds a set threshold. |

| Primary Data Source | Visual inspection, failure reports. | Historical failure statistics, usage logs. | Real-time sensor data, trend analysis. |

| Underlying Model | None (act on failure). | Statistical (e.g., Mean Time Between Failures). | Algorithmic (e.g., regression, machine learning). |

| Key Technology | Basic hand tools, visual aids. | Planning software, data logging systems. | Automated inspection vehicles, IoT sensors, AI platforms. |

| Optimization Goal | Restore function. | Maximize average component lifespan. | Maximize actual component life, minimize risk. |

Conclusion: A Data-Driven Discipline

Modern track maintenance has moved beyond its historical image of manual labor. It is a sophisticated, data-driven engineering discipline. Understanding the track as a dynamic system, governed by the laws of physics and materials science, is the foundation for any effective maintenance program. The degradation of this system is not random but follows predictable patterns of wear, fatigue, and deformation that can be measured, modeled, and managed.

The interventions we apply—from grinding to tamping to ballast cleaning—are precise engineering solutions designed to counteract these specific scientific principles of decay. By moving beyond a reactive or purely time-based approach, the industry is embracing a data-driven strategy. Predictive maintenance, enabled by advanced sensors and artificial intelligence, allows for the optimization of every intervention, maximizing asset life while minimizing both cost and risk. This principles-based approach, combining deep engineering knowledge with powerful data analytics, is what ensures the continued development of safer, more reliable, and more economically viable railway networks for the future.

- https://arema.org/ الجمعية الأمريكية لهندسة السكك الحديدية وصيانة الطرق

- https://www.uic.org/ الاتحاد الدولي للسكك الحديدية (UIC)

- https://en.wikipedia.org/wiki/Track_ballast Wikipedia – Track Ballast

- https://railroads.dot.gov/ إدارة السكك الحديدية الفيدرالية (FRA)

- https://www.transit.dot.gov/ Federal Transit Administration – Track Maintenance Standards

- https://www.sciencedirect.com/ ScienceDirect – Railway Ballast and Maintenance Research

- https://www.researchgate.net/ ResearchGate – Railway Track Maintenance Research

- https://www.loram.com/ Loram Maintenance of Way – Rail Grinding Technology

- https://www.bnsf.com/ BNSF Railway – Track Maintenance Guidelines

- https://www.up.com/ Union Pacific – Railway Engineering and Maintenance