Building Phone and Internet Equipment: A Complete Guide

Introduction: Understanding the Basics

Building telecom equipment is all about careful engineering. It’s much more than just putting parts on a circuit board. It’s a detailed process that follows strict rules where success depends on clear signals, stable temperatures, and long-lasting reliability. One tiny mistake can ruin a network installation worth millions of dollars. This guide explains the main parts that make modern, high-quality telecom equipment assembly work.

We will break down this complex field by looking at its basic parts. Here’s what this guide covers:

- Circuit board making and materials

- Choosing and placing components

- Advanced soldering and connection methods

- Important heat management strategies

- Radio frequency shielding and signal quality principles

- Complete quality control and testing procedures

This detailed guide is for engineers and technical professionals who need to understand how raw parts become reliable, high-performance hardware that powers global communication networks.

Why Technical Analysis Matters

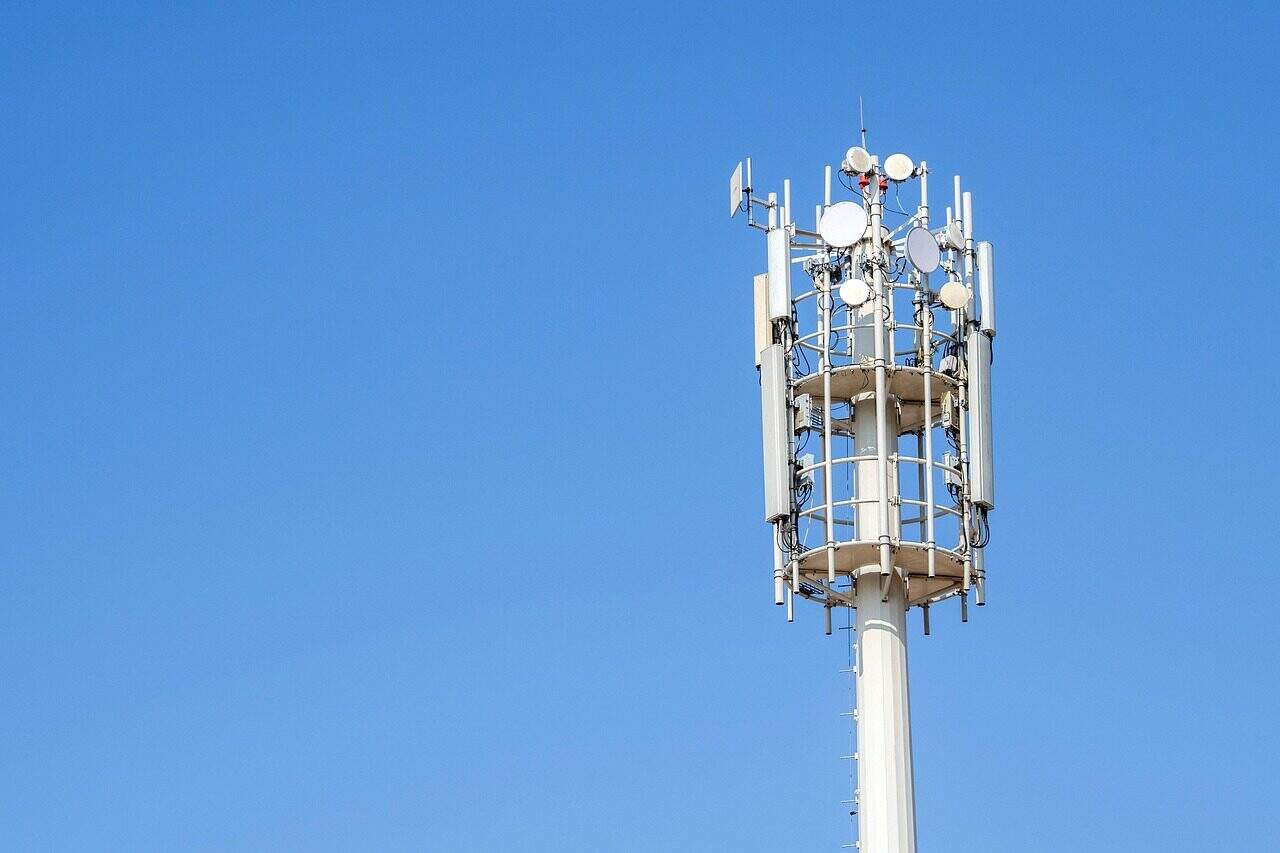

The importance of telecom equipment assembly is huge. A cell tower, main router, or optical switch isn’t a consumer device; it’s critical infrastructure expected to work perfectly for years, often in tough environmental conditions. Poor assembly directly causes major failures: signal problems that drop calls and slow data, overheating that kills components early, and interference problems that create network-wide instability. Understanding the technical details of the assembly process is essential for ensuring equipment performance and network reliability.

The Scope of Our Analysis

To provide a complete view, we will organize our analysis logically, moving from basic concepts to advanced applications and verification.

- Foundations: We start with the anatomy of telecom hardware, identifying the key components.

- Core Processes: We then explore the main assembly technologies and the Materialwissenschaft hinter them.

- Deep Dive: We will focus on the most critical technical challenges: managing heat, preserving signal integrity, and reducing interference.

- Verification: We cover the essential quality assurance and testing procedures that validate the assembly process.

- Future Outlook: Finally, we look ahead to the emerging trends shaping the future of telecom assembly.

Anatomy of Telecom Equipment

Before exploring how telecom equipment is built, we must first understand what it’s made of. Modern telecom hardware, from a 5G Radio Unit to a data center switch, is a complex system of specialized components integrated onto a central platform.

The Central Nervous System: PCBAs

The Printed Circuit Board Assembly (PCBA) is the backbone of any piece of electronic equipment. It provides both the physical structure for mounting components and the complex network of conductive pathways that allow them to communicate. In the telecom sector, these are not standard circuit boards. They are often complex, multi-layer boards—sometimes with 20 layers or more—that use specialized materials to handle high-frequency signals with minimal loss. The entire assembly process follows strict standards, such as IPC-A-610, which defines the quality criteria for electronic assemblies and ensures a baseline of quality and reliability.

Core Processing and Logic

At the heart of any telecom device are the components responsible for processing data at incredible speeds.

- Application-Specific Integrated Circuits (ASICs): These are custom-silicon chips designed from the ground up to perform a single, highly specialized function, such as packet forwarding or digital signal processing. Their fixed design delivers maximum performance and power efficiency for a known workload.

- Field-Programmable Gate Arrays (FPGAs): These chips offer a powerful alternative to ASICs. They contain a matrix of configurable logic blocks that can be programmed in the field, providing critical flexibility to adapt to new protocols or evolving standards without a hardware redesign.

- Network Processors (NPUs): These are highly specialized microprocessors with architectures optimized for the operations common in networking, such as packet inspection and traffic management. They blend the performance of ASICs with the programmability of general-purpose CPUs.

RF and Optical Components

These components form the bridge between the digital processing world and the physical transmission medium, whether it’s airwaves or fiber optic cable.

- Radio Frequency (RF) Components: This family includes RF Transceivers, which convert digital data to analog radio waves and vice-versa; Power Amplifiers (PAs), which boost the signal for transmission; and Low-Noise Amplifiers (LNAs), which amplify weak incoming signals without introducing significant noise.

- Optical Transceivers: These modules convert electrical signals into light for transmission over fiber optic cables and back again. Common form factors like SFP (Small Form-factor Pluggable) and QSFP (Quad Small Form-factor Pluggable) are common in modern telecom and data center equipment. During assembly, these components require extremely careful handling to protect sensitive RF pathways and delicate optical interfaces.

Power Systems and Mechanicals

Supporting the high-performance electronics are the power and mechanical systems. This includes dedicated power supply units (PSUs) that provide stable, clean power to all components, as well as the various connectors for data and power. The mechanical enclosure, or chassis, is far more than a simple box. It is an integral part of the system, engineered to provide structural support, precise alignment for connectors, critical electromagnetic interference (EMI) shielding, and a pathway for thermal management.

Core Assembly Processes

Transforming a bare circuit board and a reel of components into a functional telecom unit involves a series of highly controlled Herstellungsverfahren. The choice of technology at each step depends on component type, board density, and performance requirements.

PCB Fabrication and Substrates

The assembly process begins with the bare Printed Circuit Board (PCB). While the fabrication of the multi-layer board itself is a separate discipline, the choice of its core material, or substrate, is a critical assembly-related decision. For low-frequency control circuits, standard FR-4 (Flame Retardant 4) glass-epoxy material is sufficient. However, for the high-frequency RF and high-speed digital sections of a telecom board, specialized materials are essential. These materials are chosen for their stable dielectric constant (Dk) and low dissipation factor (Df), which are essential for maintaining signal integrity at gigahertz frequencies.

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) | Key Application Area |

| FR-4 | ~4.5 | ~0.020 | Low-frequency control circuits, power systems |

| Rogers RO4350B | ~3.48 | ~0.0037 | Antennas, power amplifiers, 5G infrastructure |

| Taconic TLX | ~2.55 | ~0.0019 | High-frequency microwave & RF circuits |

| Isola IS680 | ~3.0 | ~0.0030 | High-speed digital, servers, 25+ Gbps applications |

Component Placement Technologies

Once the bare board is ready, components are placed onto it using one of two primary technologies.

- Surface-Mount Technology (SMT): This is the main method for modern electronics. The process involves: 1) applying a precise amount of solder paste to the component pads on the PCB; 2) using a high-speed “pick-and-place” machine to accurately position components onto the paste; and 3) passing the entire board through a reflow oven to melt the solder and form the connections. SMT is essential for placing the small, high-density components like resistors, capacitors, and complex ICs that define telecom hardware.

- Through-Hole Technology (THT): This older method involves inserting component leads through holes drilled in the PCB and then soldering them on the opposite side, typically using a wave soldering process. While largely replaced by SMT for density reasons, THT is still used for components that require superior mechanical strength, such as large connectors, bulky capacitors, and power transformers.

From an assembly engineer’s perspective, most telecom boards use both methods, leveraging the strengths of each. SMT is used for the vast majority of the logic and RF components to achieve density, while THT is reserved for the robust I/O and power connectors that will endure physical stress.

Soldering and Interconnection

The solder joint is the critical electrical and mechanical link between the component and the PCB. The process must be perfectly controlled to ensure reliability.

- Reflow Soldering: Used for SMT, this process relies on a precisely controlled temperature profile inside a long oven. The board moves through distinct zones—preheat, soak, reflow, and cooling—to activate the flux, melt the solder alloy (commonly a lead-free SAC305 alloy of tin, silver, and copper), and then cool the joints without thermal shock. The shape and duration of this profile are critical for preventing defects.

- Wave Soldering: The classic method for THT, where the underside of the board is passed over a wave of molten solder, which flows up into the through-holes and bonds the component leads.

- Selective Soldering: In mixed-technology boards, where THT components must be added after SMT reflow, selective soldering uses a miniature fountain of solder to target individual joints without disturbing nearby surface-mount components.

Across all methods, the use of flux is essential. It is a chemical agent that cleans the metal surfaces of oxides, allowing the molten solder to form a clean, strong bond between metals.

Technical Deep Dive: Key Challenges

A general overview of assembly is useful, but the true expertise lies in overcoming the specific, high-stakes challenges inherent to high-performance telecom gear. Success is defined by how well an assembly process manages heat, preserves signal integrity, and reduces interference.

Principle 1: Thermal Management

The Problem: High-power components like ASICs, FPGAs, and Power Amplifiers are the engines of telecom equipment, but they generate immense heat in a small area. A 500W processor can have a heat density far exceeding that of a kitchen stovetop. Poor heat removal leads to performance throttling as the chip protects itself, and ultimately, a drastically reduced operational lifespan due to heat-induced material degradation.

Assembly Solutions:

- Thermal Interface Materials (TIMs): These are materials—gels, pads, or pastes—applied between a hot component and its heat sink. Their sole purpose is to fill microscopic air gaps and ensure an efficient conductive path for heat to travel. Proper application during assembly is critical to avoid air pockets.

- Heat Sinks and Heat Pipes: Heat sinks increase the surface area available for heat to dissipate into the air. Heat pipes and vapor chambers are more advanced solutions that use a phase-change cycle of an internal fluid to move heat with extremely high efficiency. The assembly process must ensure secure, even-pressure mounting of these solutions. For example, aluminum is common for heat sinks (thermal conductivity ~205 W/mK), while copper (~398 W/mK) is used for higher performance.

- PCB Design Integration: Thermal management begins at the PCB level. Techniques like placing “thermal vias” directly under a component’s heat-generating pad create a direct channel for heat to conduct into the board’s internal ground and power planes, which then act as small, embedded heat spreaders.

| Lösung | Mechanismus | Target Components | Key Assembly Consideration |

| Thermal Vias | Conduction through PCB | High-power ICs (FPGAs, ASICs) | Plating thickness, via fill (conductive vs. non-conductive) |

| TIM Pads/Gels | Conduction to heat sink | Processors, Power Amplifiers | Uniform pressure, avoiding air gaps, Materialauswahl |

| Heat Sinks | Convection to air | Any high-power component | Secure mounting, correct orientation for airflow |

| Vapor Chambers | Phase change (liquid-gas) | Extremely dense, high-power compute | Integrated design, careful handling during assembly |

Principle 2: Signal Integrity and RF

The Problem: At the multi-gigahertz frequencies of 5G, Wi-Fi 6E, and high-speed backhaul, the physical characteristics of the PCBA are no longer transparent. The traces on the board act like transmission lines, and any physical imperfection introduced during assembly can corrupt the signal. Impedance mismatches cause reflections that degrade the signal, crosstalk between adjacent lines introduces noise, and material properties cause signal loss.

Assembly Solutions:

- Controlled Impedance: This starts with PCB fabrication, where the trace width, substrate material, and distance to ground planes are tightly controlled to achieve a specific impedance (e.g., 50 ohms for RF). The assembly process must respect this design and not introduce variables.

- Minimizing Stubs: Any unterminated trace length, such as the portion of a via that extends past the signal layer, acts as an “antenna stub” that can cause reflections at high frequencies. Assembly techniques like back-drilling are used to remove these stubs after soldering.

- RF Shielding: To prevent RF circuits from interfering with each other or the outside world, they are often enclosed in small metal “RF cans” or shields. The assembly process for these involves carefully soldering the shield’s perimeter to a ground trace on the PCB, creating a complete Faraday cage to contain the electromagnetic fields.

- Component Orientation: The physical placement of RF components relative to each other and to digital sections of the board is a critical assembly consideration. Rotating a component can minimize unwanted coupling and interference.

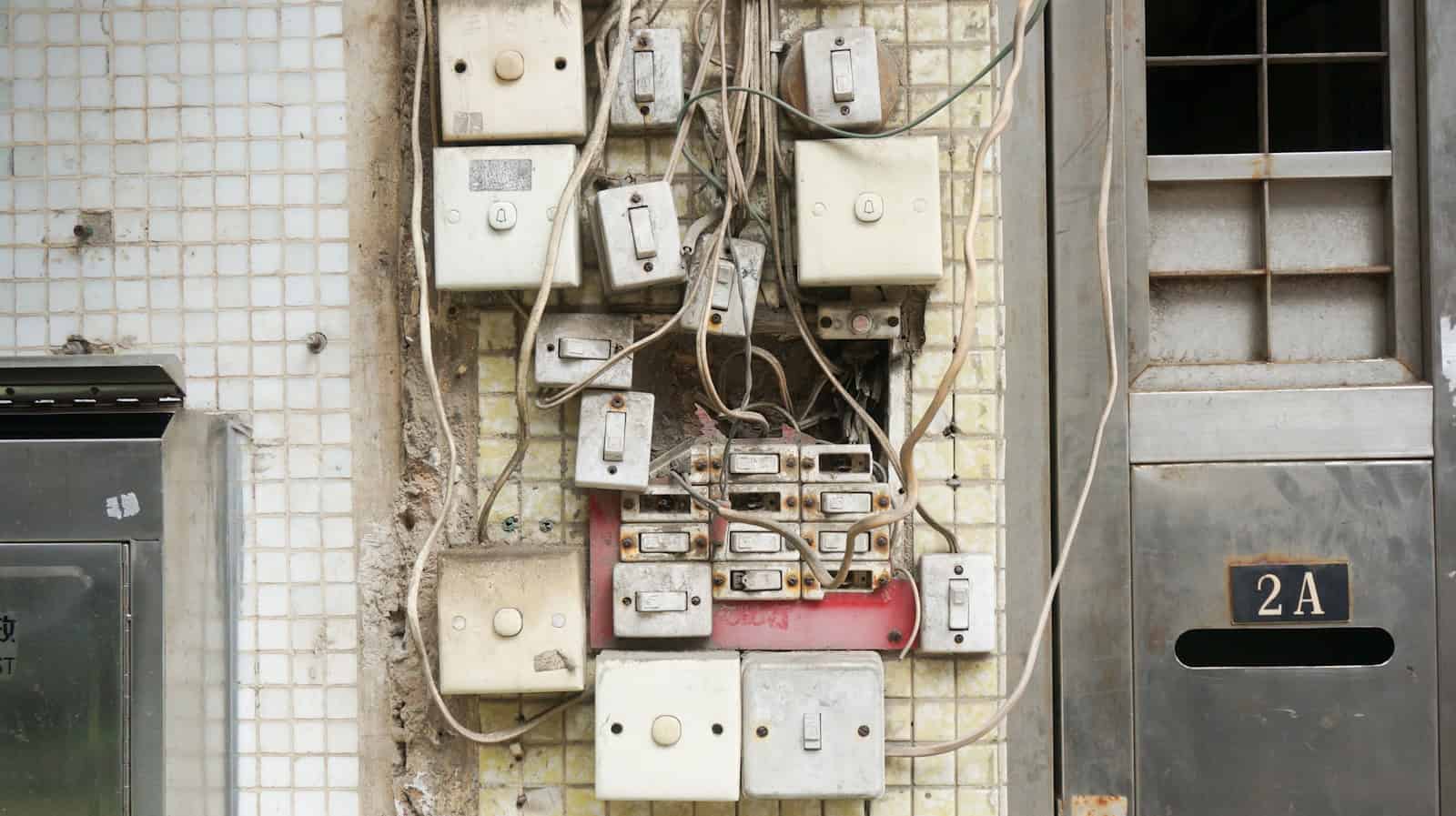

Principle 3: Mitigating EMI/EMC

The Problem: Electromagnetic Compatibility (EMC) is a two-part challenge. The equipment must not generate enough Electromagnetic Interference (EMI) to disrupt other nearby devices, and it must be immune to external EMI. In a dense rack of telecom equipment, this is a fundamental requirement for stable operation.

Assembly Solutions:

- Grounding Techniques: Proper grounding is the cornerstone of EMC. During final assembly, it is critical to ensure that all shields, connectors, and the chassis itself have a low-impedance connection to the system’s ground. This often involves specific torque requirements for screws and the use of star washers to ensure a good metal-to-metal bond.

- Gasketing and Sealing: To prevent RF energy from leaking out of (or into) the seams of a metal chassis, conductive gaskets are used. These are installed during final assembly and must be compressed correctly to provide a continuous conductive seal.

- Component-Level Filtering: Ferrite beads and other filter components are placed on power lines and I/O lines right where they enter or leave the board. Their proper placement and solid soldering during the SMT process are crucial for suppressing high-frequency noise.

Quality Assurance & Testing

A technically excellent assembly process is meaningless without empirical verification. Rigorous quality assurance (QA) and testing are not final steps; they are integrated throughout the entire manufacturing flow to catch defects at the earliest possible stage. This builds trust and guarantees the final product meets its design specifications for reliability and performance.

In-Process Inspection

Inspection occurs at multiple points during assembly to prevent defects from being passed down the line.

- Solder Paste Inspection (SPI): Before a single component is placed, a 3D SPI machine scans the board to verify the volume, alignment, and shape of every solder paste deposit. Incorrect solder volume is a leading cause of assembly defects, and SPI catches this immediately.

- Automated Optical Inspection (AOI): After components are placed and soldered in the reflow oven, an AOI machine uses high-resolution cameras to inspect each board. It compares the finished assembly to a “golden board” image, flagging placement errors (shifted or wrong parts), polarity issues (a diode placed backward), and common soldering defects like bridges or insufficient solder.

- Automated X-ray Inspection (AXI): For components like Ball Grid Arrays (BGAs) and other large ICs, the solder joints are hidden underneath the component body, invisible to an AOI camera. AXI is essential for inspecting these hidden joints. It can detect shorts, opens, and voids within the solder balls, making it essential for modern telecom hardware where BGAs are common.

Post-Assembly Functional Testing

Once a board is visually and structurally verified, it must be tested to ensure it works. This occurs in several layers.

| Test Method | Acronym | Zweck | Was es aufspürt |

| In-Circuit Test | ICT | Tests individual components on the board electrically. | Shorts, opens, wrong component values, soldering issues. |

| Flying Probe Test | FPT | A non-fixture alternative to ICT, ideal for prototypes. | Similar to ICT but slower; good for low-volume runs. |

| Functional Circuit Test | FCT | Powers up the board and verifies its real-world functionality. | Verifies that the device operates as designed (e.g., boots up, passes traffic). |

| System Level / Burn-In Test | SLT | Runs the fully assembled unit under stress (temperature, load) for an extended period. | Early-life failures, thermal issues, intermittent faults. |

The most comprehensive testing is System Level or “Burn-In” Testing. The fully assembled unit is placed in a thermal chamber, and its temperature is cycled between hot and cold extremes while it runs a full diagnostic load. This stress test is designed to accelerate and expose any latent defects or “infant mortality” failures that would otherwise occur in the first few months of field operation.

Conclusion: The Future of Assembly

Telecom equipment assembly is a science of managing physical constraints. It is the practical application of electrical and mechanical engineering principles to control heat, preserve high-frequency signals, and guarantee power integrity through a series of precise, repeatable processes. A successful assembly is not an accident; it is the result of deliberate choices in materials, process control, and layered verification.

Key Takeaways Synthesis

The core principles of excellence in telecom assembly can be summarized into four key areas:

- Material science is the foundation. The choice of PCB substrate and thermal interface materials directly affects high-frequency and thermal performance.

- Thermal management is as critical as electronic design. Heat is the primary enemy of reliability, and its mitigation must be designed into every stage of the assembly.

- Process control is paramount. Precision in SMT placement and the control of soldering profiles are what prevent latent defects that cause field failures.

- Rigorous testing is the only guarantee. A multi-stage verification strategy using SPI, AOI, AXI, and FCT is the only way to ensure a product leaves the factory with near-zero defects.

Emerging Trends on Horizon

The discipline of assembly continues to evolve, driven by the relentless demand for smaller, faster, and more powerful equipment.

- Advanced Robotics & AI: Assembly lines are becoming smarter. AI is being used to optimize pick-and-place paths, predict when a machine needs maintenance, and analyze inspection data to identify systemic process issues in real-time.

- 3D Electronics / Additive Manufacturing: The industry is exploring ways to move beyond flat PCBs, using additive manufacturing to print circuits and antennas directly onto the 3D surfaces of a product’s chassis.

- Photonics Integration: As data rates continue to climb, the boundary between electronics and optics is blurring. Co-packaged optics, where optical transceivers are placed on the same substrate as the main processing ASIC, represents a major future assembly challenge, requiring new techniques for hybrid integration.

Mastering the technical principles outlined here is fundamental for any engineer or organization involved in building today’s communication networks. As we move toward a more connected world, the expertise to assemble this critical infrastructure with precision and reliability will only grow in importance.

- IPC Standards – Wikipedia https://en.wikipedia.org/wiki/IPC_(electronics)

- IPC Standards Official Website https://www.electronics.org/ipc-standards

- Surface Mount Technology – Wikipedia https://en.wikipedia.org/wiki/Surface-mount_technology

- IPC Standards Guide – Electronic Design https://www.electronicdesign.com/technologies/embedded/article/21216532/mer-mar-electronics-ipc-standards-for-pcbs-what-are-they-and-why-do-they-matter

- IPC Standards Guide – Wevolver https://www.wevolver.com/article/mastering-ipc-standards-the-definitive-guide-for-electronics-engineers-and-pcb-designers

- SMT PCB Assembly Guide – Wevolver https://www.wevolver.com/article/smt-pcb-assembly-a-comprehensive-guide-to-surface-mount-technology-in-electronics

- Surface Mount Process – SMT Resource https://www.surfacemountprocess.com/

- What is SMT – Wevolver https://www.wevolver.com/article/what-is-smt

- SMT Manufacturing Process – Wevolver https://www.wevolver.com/article/smt-process

- Surface Mount Technology in PCB Assembly https://www.pcbnet.com/blog/surface-mount-technology-pcb-assembly-process/