China M2-M12 Stud Screw Manufacturing & Production Guide

Einführung

When your product’s quality depends on a single M6 stud screw, do you know what it takes to make it correctly? Buying from China offers great opportunities, but only if you understand the difference between a simple part and a carefully designed component. The worldwide supply chain for fasteners is complicated, and success depends on much more than finding the lowest price. It requires a deep understanding of materials, production processes, quality control, and the culture of manufacturing excellence. M2-M12 stud screws are used everywhere—from precise electronics and car parts to construction and heavy machinery—making this knowledge essential. This guide goes beyond a simple supplier list. We will break down the entire manufacturing and production process for China M2-M12 stud screws, giving you the knowledge to make smart buying decisions that focus on quality, reliability, and long-term value.

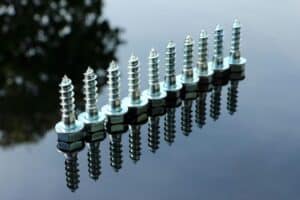

Understanding the M2-M12 Stud Screw

Before diving into the complexities of manufacturing, it is important to establish a clear, common understanding of the component itself. This basic overview ensures that all terms and specifications are clear, setting the stage for more technical discussions. For professional buyers and engineers, precision in language is the first step toward precision in manufacturing.

What is a Stud Screw?

A stud screw, or simply a stud, is a fastener without a head. Unlike a typical bolt or screw, it does not have a formed head for turning. Instead, it is a rod that has threads on one or both ends. This design allows it to be permanently installed into a threaded hole, after which a nut can be used to secure a matching part.

The most common types include:

- Fully Threaded Studs: Threaded along their entire length. These are versatile and can be used in various clamping applications or cut to custom lengths.

- Double-End Studs: Have threads on both ends with an unthreaded middle section. These are designed for specific flange or component matching applications where one end is semi-permanently installed.

Its function is different from a bolt, which passes through unthreaded holes and is secured by a nut, or a screw, which typically threads into its own matching hole.

Importance of M2-M12

The M2 to M12 metric size range covers most mechanical and electronic assembly needs. Understanding the typical uses for these sizes is key to specifying the correct component and understanding the manufacturing details at each scale.

- M2-M4: This range is the domain of precision. These small-diameter studs are critical in consumer electronics for securing circuit boards (PCBs), mounting components within cases, and in compact mechanical assemblies like those found in robotics or medical devices.

- M5-M8: The workhorse range for general engineering. These sizes are everywhere in the automotive industry for attaching trim, brackets, and non-critical engine components. They are also standard in industrial machinery for mounting guards, panels, and control boxes.

- M10-M12: These larger diameters enter the realm of light structural applications. They are used for engine and transmission mounts, assembling heavy equipment frames, and in certain types of construction and infrastructure projects where high clamping force and tensile strength are required.

The Core Manufacturing Process

Understanding how a stud screw is made is the most powerful tool a buyer can have. It transforms the conversation with a potential supplier from a simple price negotiation to a technical evaluation of their capabilities. A high-quality China M2-M12 stud screw is not merely machined; it is engineered through a multi-stage process where each step is a critical quality checkpoint.

A Step-by-Step Journey

- Raw Material Inspection & Preparation

The journey begins with large coils of steel wire rod. The first and most critical step is Incoming Quality Control (IQC). The manufacturer must verify the material certificate from the steel mill, confirming its chemical composition (e.g., carbon, manganese, chromium content) matches the required grade. A sample is often tested with a spectrometer for verification. For cold forming, the raw material must have the right flexibility. This is achieved through spheroidize annealing, a controlled heating and cooling process that softens the steel, making it moldable and preventing cracks during forming.

- Wire Drawing and Straightening

The raw wire rod, which may have a diameter larger than the final screw, is pulled through a series of dies. This wire drawing process reduces its diameter to the precise dimension required for the specific stud size being produced. This step is critical for ensuring dimensional accuracy and a smooth surface finish before the forming process begins. The wire is then straightened to ensure it feeds correctly into the next stage.

- Cold Heading / Cold Forming

This is the heart of modern fastener manufacturing. Instead of being heated, the wire is fed into a cold heading machine at room temperature. A series of powerful punches and dies then form the basic shape of the stud blank. For double-end studs, this might involve forming a chamfer or a specific end profile. This process is incredibly fast and efficient. More importantly, cold forming work-hardens the material, improving its grain structure and inherent strength, resulting in a component with superior dimensional accuracy and fatigue resistance compared to machined parts.

- Gewindewalzen (Not Cutting)

This is a must-have process for any high-quality stud screw. After forming, the blanks are fed into a thread rolling machine. Here, instead of cutting away material to create threads, hardened steel dies press and roll against the blank with immense force. This displaces the steel and forms the threads through plastic deformation. The benefits are significant: rolled threads have a denser grain structure, superior surface finish, and dramatically higher fatigue strength than cut threads, which cut through the material’s grain flow and create stress points.

- Wärmebehandlung

For medium carbon and alloy steel studs (e.g., Class 8.8, 10.9, 12.9), heat treatment is what gives the required mechanical properties. The studs are heated to a specific temperature in a controlled-atmosphere furnace (quenching) and then rapidly cooled. This makes them very hard but also brittle. The subsequent tempering process involves reheating them to a lower temperature to reduce brittleness and achieve the target balance of hardness, tensile strength, and toughness. Precise control of furnace temperature, time, and atmosphere is vital to prevent issues like decarbonization (loss of surface carbon, leading to soft threads) or quench cracking.

- Surface Treatment & Plating

Unless the stud is made of stainless steel, a protective coating is required to prevent corrosion. The choice of finish depends on the application’s environmental conditions and cost considerations.

- Zinc Plating (Clear/Yellow/Black): This is the most common and cost-effective option, providing good corrosion resistance for general indoor or mild outdoor use. The color (clear/blue, yellow, or black) comes from a subsequent passivation/chromate process.

- Black Oxide: A conversion coating that provides mild corrosion resistance and anti-galling properties. It is often chosen for its aesthetic appearance and to retain a light oil film.

- Hot-Dip Galvanizing (HDG): For harsh outdoor or corrosive environments. This process involves dipping the studs in molten zinc to create a thick, durable, and sacrificial coating. It is less common for small diameters like M2-M4 due to the coating thickness.

- Passivation: A chemical process used exclusively for stainless steel studs. It removes free iron from the surface and enhances the formation of the natural, corrosion-resistant passive oxide layer.

- Final Inspection and Packaging

The final stage involves a battery of quality checks on a statistical sample of the finished batch. This includes dimensional verification, thread checking with gauges, and testing the plating thickness. After passing inspection, the studs are often lightly oiled to provide additional protection during transit and storage. They are then carefully counted and packed into strong, clearly labeled boxes to prevent damage and ensure easy identification upon arrival.

Material Selection Guide

The choice of material is the single most important factor determining a stud screw’s performance, durability, and cost. A decision made without a full understanding of the trade-offs can lead to early product failure or unnecessary expense. Sourcing a China M2-M12 stud screw requires a clear specification of the material grade based on the application’s demands for strength, corrosion resistance, and temperature tolerance.

Common Material Categories

The materials used for M2-M12 stud screws fall into three primary families:

- Carbon Steel: The most common and economical choice, available in low, medium, and high carbon varieties. Its properties are highly dependent on carbon content and subsequent heat treatment.

- Alloy Steel: Carbon steel with other elements (like chromium, molybdenum, nickel) added to enhance properties like strength, hardness, and toughness, especially after heat treatment.

- Stainless Steel: An iron-based alloy containing a minimum of 10.5% chromium, which creates a passive, corrosion-resistant surface layer. It is the material of choice for applications where rust prevention is most important.

Unterschiedliche Materialien im Vergleich

To make an informed decision, it’s crucial to compare these materials directly. The following table provides a clear framework for selecting the right grade for your M2-M12 stud screw application.

Table 1: M2-M12 Stud Screw Material Comparison

| Material Typ | Common Grades | Wichtige Eigenschaften | Typical Applications | Relative Cost |

| Low Carbon Steel | Q235, C1018, C1022 | Low strength, good formability, requires plating for corrosion resistance. | General-purpose, non-structural uses, consumer electronics enclosures, light-duty brackets. | Niedrig |

| Medium Carbon/Alloy Steel | C1045, SCM435, 40Cr | High strength after heat treatment (enabling Class 8.8, 10.9, 12.9). Good toughness and wear resistance. | Automotive engines, transmissions, machinery assembly, structural connections requiring high tensile strength. | Mittel |

| Stainless Steel (Austenitic) | 304 (A2), 316 (A4) | Excellent corrosion resistance. Non-magnetic. Lower strength than heat-treated alloy steel. 316 offers superior resistance to chlorides. | Food processing equipment, marine applications, medical devices, outdoor architectural fixtures, chemical processing. | Hoch |

| Stainless Steel (Martensitic) | 410 | Can be heat-treated for higher hardness and strength than 304/316. Magnetic. Moderate corrosion resistance (less than 304). | Applications requiring both moderate strength and some corrosion resistance, such as valve parts or cutlery. | Medium-High |

When specifying, move beyond generic terms. Instead of “carbon steel,” specify “Medium Carbon Alloy Steel, SCM435, heat-treated to Property Class 10.9.” Instead of “stainless steel,” specify “Stainless Steel, AISI 316 (A4), passivated.” This level of precision eliminates confusion and ensures you receive a component that performs as designed.

Understanding International Standards

In the world of fasteners, standards are the universal language of quality and compatibility. They provide a precise, clear framework for dimensions, mechanical properties, and testing procedures. Relying on standards is essential when sourcing a technical component like a China M2-M12 stud screw. They are your primary tool for ensuring the part you receive is the part you designed.

Why Unclear Specs Fail

Submitting a request for “100,000 pcs M8 x 50mm stud screw” is a recipe for disaster. Without specifying a standard, you leave critical attributes open to the manufacturer’s interpretation. This can result in:

- Incorrect thread pitch or tolerance, leading to assembly failures.

- Wrong material strength (e.g., receiving a low-strength Class 4.8 stud when a high-strength Class 8.8 was needed).

- Dimensional variations that make the part unusable in your application.

A professional manufacturer will always ask for the governing standard. A supplier who is willing to produce a part without this information is a significant red flag. Following internationally recognized standards is a primary indicator of a manufacturer’s technical competence and commitment to quality.

Key Global Standards

Your technical specification or drawing must reference the relevant standards. For M2-M12 stud screws, several key ISO, DIN, and ASME standards are essential to know. The following table outlines the most critical ones and what they govern.

Table 2: Essential International Standards for M2-M12 Stud Screws

| Standard | Governs | Key Relevance for M2-M12 Stud Screws |

| ISO 898-1 | Mechanical Properties | This is the most critical standard for strength. It defines property classes like 4.8, 8.8, 10.9, and 12.9 for carbon and alloy steel fasteners, specifying their tensile strength, proof load, and hardness. |

| DIN 976-1 / DIN 975 | Dimensions | These German standards specify the dimensions for fully threaded studs (Stehbolzen). DIN 976-1 is the current standard for metric stud bolts and is widely used globally. DIN 975 refers to threaded rods, often in 1-meter lengths. |

| DIN 939 | Dimensions | This standard specifies dimensions for double-end studs where the tap end (the end screwed into a component) has a specific thread length of 1.25 times the nominal diameter (1.25d). |

| ASME B18.31.2 | Dimensions | This is the common American standard for continuous thread studs. Citing this standard is important if your product is primarily for the US market or needs to interface with ASME-compliant components. |

| ISO 3506-1 | Mechanical Properties | This standard is the equivalent of ISO 898-1 but for corrosion-resistant stainless steel fasteners. It defines grades like A2-70 or A4-80, specifying the material type (A2 for 304, A4 for 316) and strength (70 for 700 MPa tensile strength). |

A complete specification on a drawing might read: “Stud, Fully Threaded, M10x80, per DIN 976-1, Material SCM435 Alloy Steel, Property Class 10.9 per ISO 898-1, Zinc Plated Clear Cr3+.” This leaves no room for error.

Quality Control: Your Protection Against Defects

In high-volume manufacturing, defects are a statistical certainty. The difference between a world-class supplier and a poor one is not the absence of defects, but the presence of a strong system to find and eliminate them before they reach the customer. For a critical component like a stud screw, a comprehensive Quality Control (QC) plan is your protection against product failure, recalls, and damage to your reputation.

A Continuous Process

Quality is not achieved by a single inspection at the end of the production line. It must be a continuous process, built into every stage from raw material purchasing to final packaging. When evaluating a Chinese manufacturer, you must look for evidence of this integrated approach. A competent supplier will be proud to show you their quality management system in action.

Key Inspection Points

A strong QC workflow is broken down into three main phases: Incoming, In-Process, and Final Quality Control. Here is what you should expect to see at each stage:

- IQC (Incoming Quality Control): This is the first line of defense.

- The factory must have a documented process for verifying the Mill Test Certificates (MTC) that accompany each coil of steel wire, confirming the heat number and chemical composition.

- A good factory will use a handheld spectrometer to perform their own spot-check analysis of the raw material to verify it matches the certificate.

- IPQC (In-Process Quality Control): This involves monitoring production in real-time.

- Operators should perform first-piece and periodic dimensional checks after cold heading to ensure the blanks are within tolerance.

- After thread rolling, thread quality must be checked frequently using Go/No-Go gauges. These simple tools quickly verify that the thread pitch diameter is within its upper and lower limits.

- During heat treatment, furnace temperature charts and process logs must be maintained to provide a traceable record that the correct thermal cycle was applied.

- FQC (Final Quality Control): Before shipment, a statistically significant sample from the finished batch is subjected to a battery of rigorous tests in the factory’s quality lab. This is your final guarantee of compliance. Essential FQC tests include:

- Dimensional checks: Using digital calipers, micrometers, and often a profile projector or vision measuring system to verify length, diameter, chamfers, and thread profile against the drawing.

- Mechanical tests: This is a destructive test to confirm strength. It includes a tensile strength test to find the ultimate breaking point, a proof load test to ensure the stud can withstand its design load without permanent deformation, and a Härteprüfung (Rockwell or Vickers) to verify the effectiveness of heat treatment.

- Plating thickness test: Using an X-ray fluorescence (XRF) analyzer to measure the thickness of the zinc or other coating in microns, ensuring it meets the specification for corrosion protection.

- Salt spray test: To verify the corrosion resistance of the plating by exposing samples to a saline mist for a specified number of hours (e.g., 48, 96, or 240 hours) and checking for red rust.

Importance of QMS

A formal Quality Management System (QMS) certification, such as ISO 9001, is a good baseline indicator that the manufacturer has structured processes and is committed to continuous improvement. For automotive applications, the IATF 16949 certification is the gold standard. However, a certificate on the wall is not a substitute for seeing the system in practice. Always ask to see the documentation and the lab where these tests are performed.

The Complete Sourcing Guide

Finding the right manufacturer for your China M2-M12 stud screw is the final and most critical piece of the puzzle. It requires a strategic approach that goes far beyond browsing online marketplaces. This section provides a practical, experience-based guide to finding, evaluating, and working with Chinese suppliers to build a reliable and high-performing supply chain.

Beyond B2B Portals

While B2B platforms like Alibaba and Made-in-China.com are useful starting points for creating a long list of potential suppliers, they should not be your only tool. To find true manufacturing partners, we recommend a multi-channel approach:

- Industry Trade Fairs: Attending events like the Fastener Expo Shanghai or other specialized industrial fairs allows for face-to-face meetings. You can handle product samples, have in-depth technical discussions, and get a feel for a company’s professionalism and focus.

- Professional Sourcing Agents: For companies new to sourcing from China, a reputable sourcing agent can be invaluable. They provide on-the-ground expertise, language skills, and a pre-vetted network of factories, significantly reducing your risk.

Identifying Factories vs. Traders

One of the first challenges is distinguishing between a genuine manufacturer and a trading company. A trading company can be useful for consolidating small orders of various items, but for a technical component like a stud screw where process control is most important, direct factory engagement is usually better.

Here’s how to tell the difference: ask for a live video tour of the facility. A factory will be able to walk you through their cold heading, thread rolling, and heat treatment departments. A trader cannot. Also, ask for a copy of their business license. A true manufacturer will have “manufacturing” (生产型, shēngchǎn xíng) listed in their scope of business.

Supplier Evaluation Checklist

Once you have a shortlist, a systematic evaluation process is essential. Use the following checklist to ask targeted questions that reveal a supplier’s true capabilities and commitment to quality. The quality of their answers is often more telling than the answers themselves.

Table 3: China Stud Screw Manufacturer Evaluation Checklist

| Kategorie | Key Question to Ask | What to Look For (Green Flag) | Red Flag |

| Technical Capability | “Can you show me your heat treatment furnace and thread rolling machines? Do you perform these processes in-house?” | In-house control over key processes, especially heat treatment and thread rolling. They can clearly explain their process control parameters. | They outsource all critical processes to “partner factories.” Answers are vague and they cannot provide technical details. |

| Quality System | “Can you share a sample PPAP (Production Part Approval Process) or a full final inspection report for a similar M-size stud?” | They readily provide a detailed report showing dimensional results, material chemistry, mechanical test data (tensile, proof, hardness), and plating thickness. They have ISO 9001 or even IATF 16949 certification. | They can only provide a simple “QC Passed” stamp or a basic checklist. They have no formal reports or claim they are “confidential.” |

| Experience & Focus | “What percentage of your business is M2-M12 fasteners? What are the main industries you currently supply to?” | They specialize in small-to-medium diameter fasteners and have demonstrable experience supplying to your industry (e.g., automotive, electronics, medical). | They claim to make everything from tiny M2 screws to massive M48 bolts. This lack of focus often means they are a jack-of-all-trades, master of none. |

| Communication | “Who will be my primary technical contact? Is your sales and engineering team fluent in English?” | They assign you a dedicated sales engineer who can read technical drawings, discuss standards (ISO, DIN), and answer questions without constantly needing to “check with the engineer.” | The salesperson is purely a communicator and cannot answer basic technical questions. Communication is slow and prone to misunderstandings. |

| Transparency | “We require a third-party audit of your facility and a pre-shipment inspection for our first order. Is that acceptable?” | An enthusiastic “yes.” A confident manufacturer welcomes scrutiny as an opportunity to build trust and showcase their capabilities. | Hesitation, attempts to charge excessive fees for an audit, or an outright refusal. This is a major warning sign. |

Conclusion: Building a Strong Partnership

Sourcing China M2-M12 stud screws is a process that demands far more than a simple focus on unit price. As we have explored, true success is built on a foundation of technical knowledge and strategic care. It requires a commitment to understanding the details of the manufacturing process, from the selection of raw materials to the specifics of heat treatment and thread rolling. It is about speaking the universal language of international standards to ensure global compatibility and performance.

The key pillars of a successful sourcing strategy are clear: a deep understanding of the manufacturing process, the discipline to specify correct materials and standards, an insistence on a strong and verifiable QC plan, and a careful process for evaluating your supplier. By moving beyond a simple buying mindset, you can identify a manufacturer who operates not as a mere supplier, but as a genuine partner in your product’s success. By investing the time and effort to follow the process outlined in this guide, you are not just buying a part; you are building a resilient, high-quality, and cost-effective supply chain for the long term.

Referenz-Links:

- ISO 898-1 – Mechanical Properties of Fasteners Standards https://www.iso.org/

- Wikipedia – ISO 898 Fastener Standards https://en.wikipedia.org/wiki/ISO_898

- ASTM International – Fastener Standards and Testing https://www.astm.org/

- Institut für industrielle Verbindungselemente (IFI) https://indfast.org/

- SAE International – Fastener Specifications https://www.sae.org/

- Portland Bolt – Fastener Technical Resources https://www.portlandbolt.com/

- TR Fastenings – Engineering Data and Standards https://www.trfastenings.com/

- Engineers Edge – Fastener Design and Standards https://www.engineersedge.com/

- ResearchGate – Fastener Manufacturing Research https://www.researchgate.net/

- ScienceDirect – Materials Science and Fastener Research https://www.sciencedirect.com/