Der Leitfaden für Ingenieure zum Testen der Spannkraft

Die Rolle der Spannkraft

In der heutigen Welt der Technik hängt die Festigkeit von zusammengesetzten Produkten oft von einem wichtigen Faktor ab: der Klemmkraft. Bei dieser Kraft handelt es sich um den Druck, der beim Anziehen eines Befestigungselements, z. B. einer Schraube, entsteht. Sie ist die Kraft, die Teile zusammenhält, äußeren Belastungen entgegenwirkt und dafür sorgt, dass eine Verbindung während ihrer gesamten Lebensdauer einwandfrei funktioniert. Diese Kraft zu verstehen und zu überprüfen ist nicht nur eine Übung im Klassenzimmer, sondern eine Grundvoraussetzung für Sicherheit, Qualität und Leistung. Diese Leitfaden gibt Ihnen eine detaillierte technische von grundlegenden Ideen bis hin zu fortgeschrittenen Prüfmethoden und dem Ablesen von Daten für Ingenieure in der Praxis.

Was ist Spannkraft

Die Klemmkraft, auch Vorspannung oder Schraubenspannung genannt, ist die Dehnungskraft, die beim Anziehen eines Befestigungselements entsteht. Es ist wichtig zu wissen, dass es sich hierbei um einen Unterschied zum Drehmoment handelt, das lediglich die auf das Verbindungselement ausgeübte Drehkraft darstellt. Die Klemmkraft entsteht, wenn dieses Drehmoment die Reibung überwindet und die Schraube wie eine steife Feder dehnt. Diese gespeicherte elastische Energie erzeugt die drückende Vorspannkraft auf die Verbindungsteile. Wie das funktioniert, hängt von der jeweiligen Situation ab:

- Verschraubte Verbindungen: Sie stellt sicher, dass die Verbindung seitliche und ziehende Lasten aufnehmen kann, ohne zu verrutschen oder sich zu lösen, und verhindert so Ermüdungsbrüche.

- Spritzgießen: Sie hält die beiden Hälften einer Form gegen den enormen Druck des geschmolzenen Kunststoffs geschlossen und verhindert so Fehler wie Grate.

- Spanntechnik: Sie hält ein Werkstück sicher fest und verhindert Bewegungen bei Bearbeitungen mit hoher Kraft, was für die Maßgenauigkeit entscheidend ist.

- Schweißen: Sie sorgt dafür, dass die Teile präzise ausgerichtet sind und in engem Kontakt stehen, was eine ordnungsgemäße Verschmelzung gewährleistet und den Verzug reduziert.

Warum genaue Tests wichtig sind

Die richtige Messung der Spannkraft ist absolut notwendig, da sowohl zu wenig als auch zu viel Kraft zu Fehlern führt. Eine falsche Vorspannkraft ist ein versteckter Fehler, der nur darauf wartet, sich zu zeigen.

Eine zu geringe Kraft ist eine Hauptursache für das Versagen von Verbindungen. Sie kann zum Verrutschen der Verbindung bei seitlicher Belastung, zu Flüssigkeits- oder Gaslecks in abgedichteten Verbindungen, zum Lösen durch Vibration und beim Gießen führen, teures Material Abfälle durch Schimmelbildung.

Andererseits ist zu viel Kraft ebenso schädlich. Sie kann zum sofortigen Versagen führen, indem sie das Gewinde ausreißt oder das Befestigungselement selbst bricht. Noch heimtückischer ist es, wenn die Schraube über ihre Elastizitätsgrenze hinaus belastet wird, so dass sie nachgibt und ihre Fähigkeit verliert, die Vorspannung zu halten. Sie kann auch die eingespannten Teile beschädigen, indem sie weiche Materialien zerdrückt oder Flansche verformt, und sie kann die Maschinen unnötig belasten, was zu frühzeitigem Verschleiß führt.

Artikel Fahrplan

Dieser Artikel bietet Ihnen einen vollständigen Rahmen für das Verständnis und die Durchführung von Spannkraftprüfungen in der Praxis. Wir werden zunächst die Physikalische Grundlagen der Beziehung zwischen Drehmoment, Reibung und die daraus resultierende Kraft. Anschließend werden wir die verschiedenen Prüfmethoden vergleichen, von einfachen Drehmomentprüfungen bis hin zu hochpräzisen direkten Messverfahren. Danach werden wir die kritischen Faktoren, die sich auf die Genauigkeit auswirken, im Detail erläutern und einen praktischen Leitfaden für das Ablesen von Prüfdaten und die Behebung gängiger Probleme bereitstellen.

Physik der Spannkraft

Ein solides Verständnis der Klemmkraft beginnt mit den zugrunde liegenden physikalischen und mechanischen Prinzipien. Ohne diese Grundlage wird die Prüfung zu einem Black-Box-Verfahren, und die Fehlersuche wird zu einem Ratespiel. Wenn Ingenieure die Mechanik der Krafterzeugung verstehen, können sie intelligente Entscheidungen über die Konstruktion der Verbindung, die Anzugsstrategie und die Auswahl der Prüfmethode treffen.

Drehmoment, Spannung und Kraft

Die gängigste Methode zum Anziehen eines Befestigungselements ist die Anwendung eines bestimmten Drehmoments. Die Beziehung zwischen diesem Eingangsdrehmoment und der resultierenden Klemmkraft (Schraubenspannung) ist jedoch sehr variabel und indirekt. Der größte Teil des aufgebrachten Drehmoments trägt nicht zur nützlichen Vorspannung bei. Es wird durch Reibung verbraucht. Die Beziehung wird durch diese einfache Gleichung gesteuert:

F = T / (K * D)`

- F: Schraubenvorspannung/Klemmkraft. Dies ist die Dehnungskraft in der Schraube, die der Quetschkraft auf die Verbindung entspricht.

- T: Angewandtes Drehmoment. Die Drehkraft, die auf die Mutter oder Bolzenkopf.

- K: Nut-Faktor (oder Reibungskoeffizient). Dies ist eine Zahl ohne Einheiten, die alle Reibungs- und geometrischen Variablen der Verbindung kombiniert.

- D: Nenndurchmesser der Schraube.

Die entscheidende Größe ist hier der Mutterfaktor K. Er berücksichtigt die Reibung an zwei Stellen: zwischen dem Gewinde der Schraube und der Mutter sowie zwischen der sich drehenden Mutter oder dem Schraubenkopf und der Klemmfläche. Für viele ist es schockierend, dass die Reibung einen enormen Teil des aufgebrachten Drehmoments verbraucht. Normalerweise gehen etwa 50% des Drehmoments durch die Reibung unter der Mutter/dem Schraubenkopf und weitere 40% durch die Gewindereibung verloren. Das bedeutet, dass nur etwa 10% des aufgebrachten Das Drehmoment erzeugt tatsächlich die Vorspannkraft. Da die Reibung sehr empfindlich auf Schmierung, Oberflächenbeschaffenheit und Installationsgeschwindigkeit reagiert, ist es natürlich unzuverlässig, sich bei kritischen Anwendungen nur auf das Drehmoment zu verlassen.

Hookesches Gesetz und Dehnung

Ein direkterer Weg, die Klemmkraft zu ermitteln, besteht darin, die Schraube als Präzisionsfeder zu betrachten. Innerhalb ihrer Elastizitätsgrenze folgt eine Schraube dem Hooke'schen Gesetz: Der Betrag, um den sie sich dehnt, steht in direktem Zusammenhang mit der auf sie ausgeübten Kraft. Durch Messung dieser kleinen Längenänderung (Dehnung) kann die Spannkraft mit hoher Genauigkeit und unabhängig von Reibungsschwankungen berechnet werden. Auf diesem Prinzip beruhen die Messverfahren mit Ultraschall und Mikrometer. Die Kontrollformel lautet:

F = A * E * (ΔL / L)`

- F: Spannkraft.

- A: Querschnittsfläche der Schraube. Dies ist nicht die Nennfläche, sondern die effektive Fläche, die die Last trägt.

- E: Elastizitätsmodul (Young's Modulus) des Schraubenmaterials. Damit wird die Steifigkeit des Materials gemessen (z. B. ~205 GPa oder 30.000.000 psi für Stahl).

- ΔL: Die Längenänderung der Schraube (Dehnung) durch das Anziehen.

- L: Die ursprüngliche effektive Länge des Bolzens, der gedehnt wird.

Diese Beziehung zeigt, dass wir, wenn wir die Dehnung (ΔL) einer Schraube mit bekannten Eigenschaften (A, E, L) genau messen können, direkt die Klemmkraft (F) berechnen können, die sie ausübt.

Material- und Verbindungseigenschaften

Die letztendlich erreichte Spannkraft ist auch eine Funktion des gesamten Verbindungssystems. Die Steifigkeit der Schraube im Vergleich zur Steifigkeit der eingespannten Teile bestimmt, wie sich die Verbindung unter äußeren Belastungen und Temperaturschwankungen verhält. Eine Verbindung mit weichen Teilen, wie z. B. mehreren Dichtungen, hat eine geringe Steifigkeit. Sie wird sich eher entspannen, wobei die Vorspannung mit der Zeit abnimmt, wenn sich die weichen Materialien setzen oder kriechen. Ein steifes Gelenk mit zwei großen Stahlplatten wird dagegen seine Vorspannung viel besser halten können. Die Materialeigenschaften der Schraube, wie z. B. ihre Güteklasse und Zugfestigkeit, bestimmen die maximale Vorspannung, die sie sicher aufnehmen kann, ohne nachzugeben. Eine hochfeste Schraube der Güteklasse 8.8 kann eine viel höhere Vorspannkraft erreichen als eine Schraube aus Baustahl der Güteklasse 4.6 derselben Größe.

Prüfverfahren für die Spannkraft

Es gibt verschiedene Methoden zur Durchführung einer Spannkraftprüfung, die von einfachen, indirekten Schätzungen bis zu hochpräzisen, direkten Messungen reichen. Die Wahl der Methode hängt davon ab, wie kritisch die Verbindung ist, von den Genauigkeitsanforderungen, dem Budget, der Zugänglichkeit und davon, ob die Prüfung für Forschung und Entwicklung, die Produktion oder die Überprüfung vor Ort gedacht ist.

Indirekte Drehmoment-Methoden

Die gebräuchlichste Methode bei der Montage ist der drehmomentbasierte Ansatz unter Verwendung eines kalibrierten Drehmomentschlüssels. Der Bediener wendet einen bestimmten Drehmomentwert an, und die Spannkraft wird auf der Grundlage der Berechnung "F = T / (K * D)" angenommen. Wie bereits erwähnt, handelt es sich hierbei um eine indirekte Methode. Ihre größte Schwäche ist die hohe Variabilität des Reibungskoeffizienten (K). Änderungen der Schmierung, des Oberflächenrosts, des Gewindezustands oder der Arbeitstechnik können dazu führen, dass die tatsächliche Vorspannung um ±25% oder mehr vom Sollwert abweicht, selbst bei einem perfekt kalibrierten Schraubenschlüssel. Diese Methode ist oft "gut genug" für unkritische Anwendungen, bei denen eine große Toleranz bei der Klemmkraft akzeptabel ist.

Direkte Messmethoden

Direkte Methoden messen eine physikalische Veränderung des Verbindungselements oder der Verbindung, die sich direkt aus der Vorspannkraft ergibt. Diese Verfahren sind weitaus genauer, da sie die Unsicherheiten der Reibung weitgehend vermeiden.

Ultraschall-Dehnungsmessgeräte

Diese fortschrittliche Methode nutzt das Prinzip der Schraubendehnung. Ein Ultraschallwandler wird auf den Schraubenkopf aufgesetzt. Er sendet einen Schallimpuls über die gesamte Länge der Schraube, der am Ende der Schraube abprallt und zurückkehrt. Das Gerät misst präzise die Laufzeit des Impulses. Diese Messung wird vor und nach dem Anziehen vorgenommen. Die Änderung der Flugzeit steht in direktem Zusammenhang mit der Längenänderung der Schraube (ihrer Dehnung). Anhand der akustischen Eigenschaften des Materials und des Hookeschen Gesetzes berechnet das Gerät die Spannkraft. Das Gerät bietet eine hohe Genauigkeit (typischerweise ±1-3%) und ist nach der anfänglichen Vorbereitung des Schraubenendes nicht invasiv, was es ideal für die Überprüfung kritischer Verbindungen vor Ort macht.

Kraftmessdosen und Kraftmessdosen

Diese Geräte sind der Goldstandard für Genauigkeit, da sie die Kraft direkt messen. Eine Kraftmessdose ist ein Gerät, das die Kraft in ein messbares elektrisches Signal umwandelt. Sie werden oft in Form einer Unterlegscheibe eingebaut und direkt unter der Mutter oder dem Schraubenkopf angebracht. Beim Anziehen des Befestigungselements wird die Kraftmessdose zusammengedrückt, und ihr Ausgang gibt in Echtzeit Aufschluss über die erzeugte Klemmkraft. Dies sind wichtige Hilfsmittel für die Laborforschung, für die Kalibrierung anderer Anzugsmethoden und für die Ermittlung des wahren Verhältnisses zwischen Drehmoment und Spannung für eine bestimmte Verbindung. Bei der Installation einer Unterlegscheibe mit Lastanzeige kann man direkt beobachten, wie die Kraftanzeige bei Anwendung des Drehmoments ansteigt, was oft die nicht lineare und uneinheitliche Beziehung zwischen den beiden aufzeigt.

Dehnungsmessstreifen

Für höchste Präzision, insbesondere in der Forschung und Entwicklung sowie bei der Fehleranalyse, können Dehnungsmessstreifen verwendet werden. Ein kleines, dünnes Foliengitter wird direkt auf den Schaft der Schraube geklebt. Wenn die Schraube angezogen und gedehnt wird, erfährt der Schaft eine Dehnung, wodurch das Foliengitter gedehnt wird und sich sein elektrischer Widerstand ändert. Diese Widerstandsänderung wird mit einer Wheatstone-Brückenschaltung gemessen und genau auf die Dehnung und damit auf die Spannung und Kraft in der Schraube bezogen. Diese Methode ist zwar äußerst genau, aber empfindlich, arbeitsintensiv und im Allgemeinen auf Laborumgebungen beschränkt.

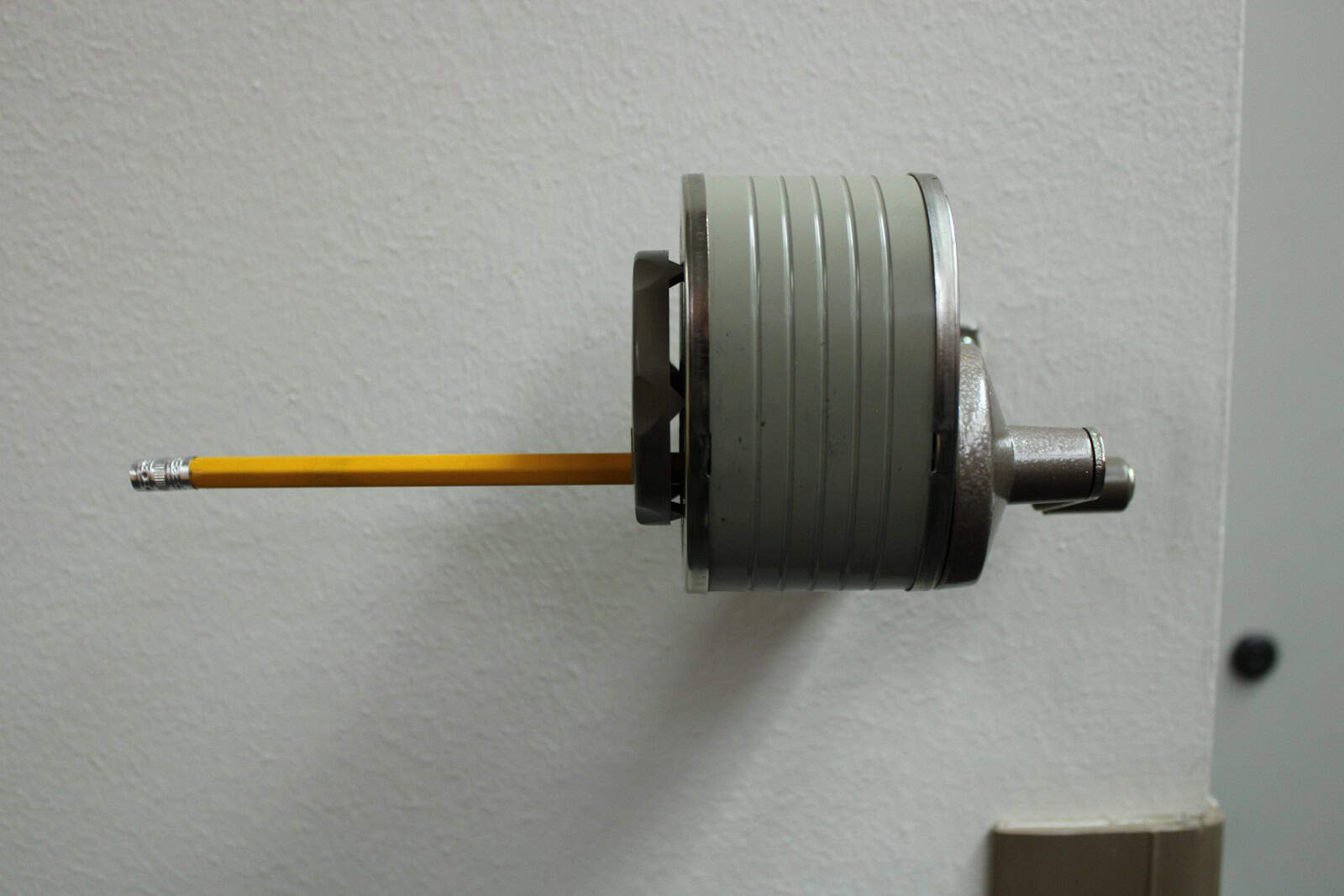

Mikrometer-Messung

Dies ist die einfachste mechanische Methode zur Messung der Schraubendehnung. Sie erfordert den Zugang zu beiden Enden der Schraube. Mit einer speziellen Messschraube wird die Gesamtlänge der Schraube vor dem Anziehen gemessen. Nach dem Anziehen wird die Messung wiederholt. Die Differenz zwischen den beiden Messwerten ist die Dehnung (ΔL). Dieser Wert kann dann in die Formel des Hooke'schen Gesetzes zur Berechnung der Kraft eingesetzt werden. Der Vorteil dieses Verfahrens liegt in seinem einfachen Konzept und den geringen Kosten für die Ausrüstung. Es ist jedoch anfällig für Bedienerfehler, erfordert präzise und saubere Messflächen und ist nur für Anwendungen mit Durchgangslöchern möglich, bei denen beide Enden des Verbindungselements zugänglich sind.

Auswahl einer Testmethode

Bei der Auswahl der richtigen Methode müssen Genauigkeit, Kosten und Anwendungsbeschränkungen gegeneinander abgewogen werden. Die folgende Tabelle enthält einen Vergleich, der bei dieser Entscheidung helfen soll.

| Methode | Grundsatz | Genauigkeit | Kosten | Anmeldung | Pro / Kontra |

| Drehmomentschlüssel | Indirekt (Drehmoment) | Niedrig bis mittel | Niedrig | Generalversammlung | Pro: Einfach und schnell. Betrug: Aufgrund der Reibung sehr ungenau. |

| Ultraschall | Direkt (Stretch) | Hoch | Hoch | Kritische Gelenke, Feldaudits | Pro: Sehr genau, nicht aufdringlich. Betrug: Erfordert Erstkalibrierung, empfindlich gegenüber Material/Temperatur. |

| Wägezellen/Waschanlagen | Direkt (Kraft) | Sehr hoch | Mittel bis Hoch | F&E, Kalibrierung, kritische Gelenke | Pro: Misst die Kraft direkt, höchste Genauigkeit. Betrug: Kann die Gelenksteifigkeit verändern, muss aber nicht dauerhaft sein. |

| Dehnungsmessstreifen | Direkt (Dehnung) | Sehr hoch | Hoch (Arbeit) | Labortests, Validierung | Pro: Äußerst präzise. Betrug: Zerbrechlich, erfordert fachmännische Installation, nicht für den Außeneinsatz geeignet. |

| Mikrometer | Direkt (Stretch) | Mittel | Niedrig | Bolzen mit Durchgangsbohrung | Pro: Kostengünstig, einfaches Konzept. Betrug: Anfällig für Bedienungsfehler, begrenzter Zugang. |

Faktoren, die die Genauigkeit beeinflussen

Das Erreichen der angestrebten Spannkraft ist nicht nur eine Frage der Wahl des richtigen Anziehwerkzeugs. Viele Faktoren können erhebliche Schwankungen in den Prozess einbringen. Ein disziplinierter technischer Ansatz erfordert die Identifizierung, das Verständnis und die Kontrolle dieser Variablen, um konsistente und zuverlässige Ergebnisse zu gewährleisten.

Die Auswirkungen der Reibung

Reibung ist die größte Einzelquelle für Fehler und Unstimmigkeiten beim drehmomentgesteuerten Anziehen. Wie bereits erwähnt, kann sie bis zu 90% der Eingangsenergie verbrauchen. Wenn die Reibung nicht kontrolliert wird, bedeutet dies, dass Sie Ihre Vorspannkraft nicht kontrollieren können. Die wichtigsten Reibungsquellen müssen kontrolliert werden:

- Unter dem Schraubenkopf oder der Mutterfläche: Dies macht etwa 50% des Drehmoments aus. Die Oberflächenbeschaffenheit, das Vorhandensein einer Unterlegscheibe und die Schmierung sind entscheidende Faktoren.

- In den Threads: Dies macht weitere 40% des Drehmoments aus. Die Qualität der Gewinde, ihre Oberflächengüte und die Schmierung sind entscheidend.

- Wirkung der Schmierung: Schmiermittel sollen den Reibungskoeffizienten verringern und, was noch wichtiger ist, stabilisieren. Ein Wechsel von einer trockenen zu einer geschmierten Schraube kann die Klemmkraft bei gleichem Drehmoment mehr als verdoppeln. Konsistenz ist der Schlüssel.

- Oberflächengüte der Bauteile: Raue, unebene oder beschädigte Oberflächen erhöhen die Reibung in unvorhersehbarer Weise, wodurch mehr Drehmoment benötigt und die endgültige Vorspannung verringert wird.

Bediener- und Werkzeug-Faktoren

Das menschliche Element und die verwendeten Werkzeuge sind wesentliche Ursachen für Abweichungen. Ein Bediener, der eine "ruckartige" Bewegung an einem Drehmomentschlüssel mit Einrastfunktion ausführt, kann leicht über das eingestellte Drehmoment hinausgehen, was zu einer übermäßigen Klemmkraft führt. Ein gleichmäßiger, kontinuierlicher Zug, bis das Werkzeug anzeigt, dass das Ziel-Drehmoment erreicht ist, ist für die Wiederholbarkeit entscheidend.

Die Kalibrierung der Werkzeuge ist ebenso wichtig. Alle Schraub- und Messgeräte, insbesondere Drehmomentschlüssel und Ultraschallgeräte, verändern sich im Laufe der Zeit und bei Gebrauch. Ein regelmäßiger Kalibrierungsplan, der auf nationale Standards rückführbar ist, ist für jeden qualitätskontrollierten Prozess obligatorisch. Gemäß Normen wie ISO 6789 sollten Drehmomentwerkzeuge in regelmäßigen Abständen kalibriert werden, z. B. jährlich oder nach einer bestimmten Anzahl von Zyklen (z. B. 5.000), um sicherzustellen, dass sie innerhalb der angegebenen Toleranz bleiben.

Umwelt- und Materialfaktoren

Die Bauteile selbst und die Umgebung, in der sie montiert werden, bringen weitere Variablen mit sich. Diese müssen sowohl bei der Konstruktion als auch beim Montageverfahren berücksichtigt werden. Die folgende Tabelle fasst die häufigsten Faktoren und Strategien zu ihrer Abschwächung zusammen.

| Faktor | Beschreibung der Wirkung | Strategie zur Risikominderung |

| Schmierung | Ändert den "Mutterfaktor" (K) drastisch. Ungeschmierte Schrauben erfordern ein viel höheres Drehmoment für die gleiche Vorspannung. | Verwenden Sie ein spezifiziertes Schmiermittel und tragen Sie es gleichmäßig auf die spezifizierten Oberflächen auf (z. B. nur Gewinde oder Gewinde und Unterkopf). Vermerken Sie den Schmierstofftyp in den Montageanweisungen. |

| Oberfläche | Rauere Oberflächen erhöhen die Reibung und erfordern ein höheres Drehmoment für eine bestimmte Vorspannung. Eine uneinheitliche Oberfläche führt zu einer hohen Streuung. | Spezifizieren und kontrollieren Sie die Oberflächenbeschaffenheit von Gegenstücken und Verbindungselementen durch die Eingangskontrolle. |

| Temperatur | Kann dazu führen, dass sich Materialien ausdehnen oder zusammenziehen, wodurch sich die Vorspannung nach der Montage ändert (thermische Effekte). Eine bei niedriger Temperatur angezogene Verbindung kann bei einer hohen Betriebstemperatur an Vorspannung verlieren. | Montieren Sie nach Möglichkeit in einer temperaturgeregelten Umgebung. Berücksichtigen Sie die unterschiedliche Wärmeausdehnung bei Konstruktionsberechnungen für Verbindungen mit ungleichen Materialien. |

| Wiederverwendung von Verbindungselementen | Durch die Wiederverwendung von Schrauben können Gewinde verschliffen (poliert) werden, wodurch sich der Reibungskoeffizient ändert. Noch kritischer ist, dass eine wiederverwendete Schraube verformt sein kann, wodurch ihre Fähigkeit, eine Vorspannung zu erreichen oder beizubehalten, verringert wird. | Folgen Sie Hersteller oder technische Richtlinien für Befestigungsmittel Wiederverwendung. Für alle kritischen Verbindungen sollten standardmäßig immer neue, zertifizierte Verbindungselemente verwendet werden. |

| Entspannung der Gelenke | Mit der Zeit können sich weiche Materialien (z. B. Dichtungen) oder sogar dicke Lackschichten unter der Klemmlast zusammendrücken, was zu einem Verlust der Vorspannung führt. Dies ist ein zeitabhängiger Effekt. | Führen Sie nach einer bestimmten Zeit (z. B. 24 Stunden) eine Nachziehsequenz durch, um die anfänglichen Setzungen auszugleichen. Verwenden Sie gehärtete Unterlegscheiben, um die Last besser zu verteilen und das Kriechen zu minimieren. |

Interpretation von Testdaten

Die Durchführung eines Spannkrafttests ist nur die halbe Miete. Der wahre Wert ergibt sich aus der korrekten Auswertung der resultierenden Daten, um fundierte technische Entscheidungen zu treffen. Dabei geht es nicht nur um einzelne Datenpunkte, sondern darum, den Gesamtzustand und die Leistungsfähigkeit des Montageprozesses zu verstehen.

Verstehen der Datenverteilung

Eine einzige Spannkraftmessung bietet nur begrenzte Einblicke. Um einen Prozess wirklich zu verstehen, muss eine statistisch signifikante Stichprobe von Verbindungen getestet werden. So können wir die Verteilung der Ergebnisse analysieren, die Aufschluss über die Konsistenz und Genauigkeit des Prozesses gibt. Die beiden wichtigsten statistischen Maße sind:

- Mittelwert (Durchschnitt): Dies ist die zentrale Tendenz Ihrer Ergebnisse. Sie gibt Aufschluss darüber, ob Sie im Durchschnitt Ihre Zielspannkraft erreichen. Ein Mittelwert, der erheblich vom Zielwert abweicht, deutet auf einen systematischen Fehler im Prozess hin (z. B. falsche Drehmomentangabe, falsche Annahme des K-Faktors).

- Standardabweichung: Dies ist ein Maß für die "Streuung" oder Variation der Ergebnisse. Eine geringe Standardabweichung zeigt einen konsistenten, wiederholbaren Prozess an, bei dem jede Verbindung eine ähnliche Vorspannkraft erreicht. Eine hohe Standardabweichung bedeutet einen unkontrollierten Prozess mit großen Schwankungen von einer Baugruppe zur nächsten, selbst wenn der Durchschnitt im Zielbereich liegt.

Gesunde vs. ungesunde Gelenke

Anhand der Datensignatur einer Verbindung kann ein Techniker schnell erkennen, ob der Prozess unter Kontrolle ist. Eine "gesunde" Verbindungssignatur zeigt, wenn sie als Histogramm aufgetragen wird, eine enge Verteilung (geringe Standardabweichung), die auf oder sehr nahe am Zielwert für die Vorspannung zentriert ist. Dies zeigt, dass der Prozess in der Lage ist, zuverlässig Verbindungen herzustellen, die den technischen Spezifikationen entsprechen.

Eine "ungesunde" Signatur weist eine große Streuung auf (hohe Standardabweichung). Die Ergebnisse können sehr unterschiedlich ausfallen, wobei einige Verbindungen zu locker und andere zu fest sind. Dies ist ein klares Anzeichen für eine unkontrollierte Variable im Prozess, wie z. B. inkonsistente Schmierung, schlechte Bedienertechnik oder Schwankungen in der Komponentenqualität. Eine andere ungesunde Signatur ist eine enge Verteilung, die weit vom Zielwert entfernt ist und auf einen systematischen Fehler hinweist, der korrigiert werden muss.

Praktische Fehlersuche

Wenn Testdaten ein Problem aufzeigen, ist ein systematischer Ansatz zur Fehlersuche erforderlich. Im folgenden Leitfaden werden häufige Symptome, die bei der Prüfung der Spannkraft beobachtet werden, den wahrscheinlichen Ursachen zugeordnet und Abhilfemaßnahmen empfohlen.

| Symptom / Problem | Mögliche Ursache(n) | Empfohlene Aktion(en) |

| Geringe Spannkraft trotz korrektem Drehmoment | - Übermäßige Reibung (kein Schmiermittel, falsches Schmiermittel, raue Oberfläche)<br>- Falscher K-Faktor bei der Berechnung verwendet<br>- Werkzeug ist nicht kalibriert<br>- Nachgeben der Schraube vor Erreichen des Zielmoments | - Überprüfen Sie, ob das richtige Schmiermittel verwendet und gleichmäßig aufgetragen wird.<br>- Überprüfen Sie die Oberflächenbeschaffenheit der Komponenten.<br>- Drehmomentwerkzeug neu kalibrieren.<br>- Führen Sie eine direkte Kraftmessung durch (z. B. mit einer Kraftmessdose), um ein echtes Verhältnis zwischen Drehmoment und Kraft zu ermitteln und die Drehmomentspezifikation anzupassen. |

| Hohe Streuung/inkonsistente Ergebnisse | - Inkonsequente oder schlampige Schmierungsverfahren<br>- Die Technik des Bedieners variiert (Geschwindigkeit, Bewegung)<br>- Qualitäts-/Maßabweichungen von Bauteilen (Schrauben, Muttern, Unterlegscheiben)<br>- Verwendung von Schlagschraubern oder anderen unkontrollierten Werkzeugen | - Standardisierung des Schmierverfahrens und Schulung der Bediener.<br>- Schulung des Bedienpersonals im richtigen und reibungslosen Gebrauch der Werkzeuge.<br>- Durchführen Qualitätskontrolle Kontrollen der eingehenden Verbindungselemente und Bauteile.<br>- Wechseln Sie zu kalibrierten Werkzeugen mit kontinuierlichem Antrieb oder mit Klickfunktion. |

| Spannkraft sinkt mit der Zeit (Relaxation) | - Kriechen der Dichtung oder Setzung<br>- Komprimierung weicher Fugenmaterialien (einschließlich Farbe)<br>- Lockerung der Vibration<br>- Thermische Wechselwirkungen | – Verwenden Sie gehärtete Unterlegscheiben, um die Last zu verteilen.<br>- Führen Sie nach einem festgelegten Zeitraum (z.B. 24 Stunden) eine Nachanwendung der Anzugskraft durch.<br>- Untersuchen Sie Verriegelungselemente, Gewindesicherungskleber oder andere Vibrationsschutzmethoden für Umgebungen mit hoher Vibration.<br>- Analysieren Sie thermische Effekte in der Konstruktionsphase. |

| Schraube versagt beim Anziehen | - Übermäßiges Drehmoment (falsche Spezifikation oder schlechtes Werkzeug)<br>- Materialfehler an der Schraube oder falsche Sorte verwendet<br>- Wiederverwendeter Bolzen, der zuvor nachgegeben hat<br>- Übermäßige Gewindereibung führt zu Torsionsversagen | - Überprüfen Sie die Drehmomentangaben und die Kalibrierung des Werkzeugs.<br>- Verwenden Sie neue, zertifizierte Schrauben von einem vertrauenswürdigen Lieferanten und überprüfen Sie die Kopfmarkierungen.<br>- Führen Sie eine strikte "Keine Wiederverwendung"-Politik für kritische Verbindungselemente ein.<br>- Achten Sie auf eine ausreichende Schmierung, um die Torsionsbelastung im Verhältnis zur Spannung zu verringern. |

Integration von Tests in die QA

Letztendlich sollte die Spannkraftprüfung nicht als isolierte Aktivität betrachtet werden, die nur dann durchgeführt wird, wenn Probleme auftreten. Stattdessen muss sie in einen umfassenden Qualitätsrahmen integriert werden, der sich von der Konstruktion und Entwicklung über die Produktion bis hin zum Service vor Ort erstreckt. Sie ist ein Instrument zur Prozessvalidierung und -kontrolle.

Technische Kernaussagen

Unsere technische Analyse hat einige kritische Prinzipien herausgearbeitet, die die Grundlage für eine robuste Klemmstrategie bilden. Ingenieure und Techniker sollten diese Punkte verinnerlichen:

- Nicht das Drehmoment, sondern die Klemmkraft ist der eigentliche physikalische Parameter, der die Integrität und Leistungsfähigkeit einer Schraubverbindung bestimmt.

- Direkte Messmethoden, z. B. mit Ultraschall oder Kraftmessdosen, bieten eine weitaus höhere Genauigkeit und Zuverlässigkeit als indirekte drehmomentbasierte Methoden, da sie die massive Variable der Reibung umgehen.

- Die Reibung ist die größte Einzelvariable beim drehmomentgesteuerten Anziehen und muss verstanden und durch Schmierung, Oberflächenbeschaffenheit und Komponentenqualität streng kontrolliert werden.

- Ein systematischer Ansatz, der alle Einflussfaktoren - einschließlich des Werkzeugs, des Bedieners, der Komponenten und der Umgebung - berücksichtigt, ist unerlässlich, um konsistente und vorhersehbare Ergebnisse zu erzielen.

Von reaktiv zu proaktiv

Die aus der Spannkraftprüfung gewonnenen Erkenntnisse ermöglichen es einem Unternehmen, von einem reaktiven Zustand (Behebung von Fehlern) zu einem proaktiven Zustand (Vermeidung von Fehlern) überzugehen. In der Forschungs- und Entwicklungsphase werden durch die Prüfung die korrekten Spezifikationen festgelegt und die Konstruktion der Verbindung validiert. In der Produktion dient es dazu, den Montageprozess zu überprüfen, zu kontrollieren und das Personal zu schulen. Das Ziel ist es, mit Hilfe dieser Daten einen so zuverlässigen und wiederholbaren Spannprozess zu entwickeln, dass die Routineprüfungen im Laufe der Zeit reduziert werden können. Ein gut verstandener und kontrollierter Prozess, der auf den hier dargelegten Grundsätzen aufbaut, ist das Markenzeichen technischer Spitzenleistungen und die Grundlage für ein sicheres, hochwertiges Produkt.

- https://www.iso.org/ ISO - Normen für Drehmomentwerkzeuge (ISO 6789)

- https://www.portlandbolt.com/ Portland Bolt - Tabellen für Schraubendrehmomente und Spannungen

- https://www.engineersedge.com/ Engineers Edge - Rechner für Drehmoment und Klemmkraft von Befestigungselementen

- https://www.astm.org/ ASTM International - Normen für die Prüfung von Verbindungselementen

- https://en.wikipedia.org/wiki/Bolted_joint Wikipedia - Verschraubte Verbindung

- https://www.futek.com/ FUTEK - Wägezellen und Kraftmesssysteme

- https://www.atlascopco.com/ Atlas Copco - Leitfaden für die Anzugstechnik

- https://www.sae.org/ SAE International - Normen für das Anzugsmoment von Befestigungselementen

- https://www.researchgate.net/ ResearchGate - Forschungspapiere zu Schraubverbindungen

- https://www.nord-lock.com/ Nord-Lock Gruppe - Verschraubungstechnik und Spannkraft