The Complete Guide to Cabinet Fastening: A Technical Guide

This is not another simple guide on how to use a screw. This is a technical guide for professionals who want more than basic instructions. We go beyond the “how” to explore the “why” of cabinet fastening. True skill in cabinet building comes from understanding how forces, materials, and fasteners work together. A cabinet is not just a static box; it is an active structure that faces constant stress. Its lifespan is not determined by one screw, but by a complete system where every part is chosen for a specific engineering reason.

In this guide, we will explore:

- En física básica of the loads and stresses a cabinet must handle.

- A ciencia de materiales view of how substrate choice determines fastening strategy.

- A mechanical breakdown of common fasteners and how they work.

- A detailed analysis of joint design, common failure types, and how to prevent them.

- Advanced concepts for achieving professional-level structural strength.

Understanding Basic Physics

To build a strong cabinet, we must first think like an engineer and picture the invisible forces acting on it. A cabinet’s stability follows principios básicos of physics. Understanding these allows for smart design that anticipates stress points and prevents failures before they happen. The cabinet must be designed to handle a lifetime of loads, both expected and sudden.

Static vs. Dynamic Loads

Every cabinet faces two main types of loads. A static load is the constant, unchanging force from the cabinet’s own weight and the long-term weight of its contents. This includes the weight of dishes in a wall cabinet or books on a shelf. It is a predictable force that we can calculate and design for directly.

A dynamic load is a temporary, often sudden, force applied during use. This includes the impact of a slamming door, the jerking motion of a full drawer being pulled open, or a person leaning against a base unit. Dynamic loads are far more destructive than static loads of the same size. Their quick application creates peak stresses that can be many times higher than the static equivalent, leading to material fatigue and sudden joint failure. A joint that can support 100 pounds of static weight may fail under the repeated dynamic shock of a 20-pound drawer.

Breaking Down the Stresses

These loads show up as four types of stress within the cabinet’s structure and its joints. A successful design effectively manages all four.

- Tension is a pulling force that tries to stretch a component or pull a joint apart. This is the main stress on the screws holding a loaded wall cabinet to the wall studs. It’s also the force that cam-lock fasteners are designed to resist, pulling two panels tightly together.

- Compression is a pushing or squeezing force. It is the main stress on the vertical sides or partitions of a base cabinet stack, which must support the weight of the countertop and any upper cabinets. It’s also the force acting on the bottom of a cabinet resting on the floor.

- Shear is a sliding force where two adjacent parts of a material or joint try to slide past one another. This is the most critical stress for most cabinet fasteners. It is the force acting on shelf pins, on the screws holding a cabinet back in place, and on dowels used for panel alignment. A fastener’s ability to resist shear is essential to preventing shelves from collapsing and frames from racking.

- Torsion is a twisting force that attempts to rotate a cabinet out of square. This is commonly known as racking. Torsion is most common when a cabinet is moved, installed on an uneven floor, or when an unbalanced load is applied, such as a heavy object placed on one corner of a shelf. A properly secured back panel is the single most effective defense against torsional forces.

Material Science and Fastening

The choice of substrate is as critical as the choice of fastener. Each material has a unique internal structure that determines how it holds a fastener and how it responds to stress. A fastening strategy that works well in one material can lead to complete failure in another. Understanding the material science is essential for professional results.

Solid Wood

Solid wood is an anisotropic material, meaning its physical properties depend on direction. It is exceptionally strong along the grain but comparatively weak across it. This has major implications for fastening. A screw driven into the face or edge grain of a board will hold with great strength because its threads are engaging with long, continuous wood fibers. A screw driven into end grain, however, has significantly lower holding power because its threads are merely separating the fibers. Furthermore, solid wood expands and contracts with changes in humidity, mainly across its width. Joint design must accommodate this movement to prevent splitting and joint failure.

Plywood

Plywood’s strength comes from its layered structure. It is built from thin layers of wood veneer (plies) glued together, with the grain direction of each layer oriented perpendicular to the last. This cross-graining distributes stress over a wide area, neutralizing the directional weakness of solid wood. The result is a panel with excellent dimensional stability and superior fastener-holding power in all directions. The screw threads engage with multiple layers of cross-oriented fibers, making it highly resistant to splitting and providing excellent pull-out strength, even near an edge.

Medium-Density Fiberboard (MDF)

MDF is a uniform material made from fine wood fibers bonded with resin under high pressure. Its uniform density provides a perfectly smooth surface ideal for painting, but its internal structure presents fastening challenges. While screws hold reasonably well in the face of MDF, its edge-holding power is poor. The fine, short fibers offer little resistance to screw threads, making it prone to thread stripping and pull-out, especially under dynamic loads. Fastening too close to an edge without a properly sized pilot hole will almost certainly cause the material to split and bulge.

Particleboard

Particleboard is composed of larger wood particles (chips) bonded with resin. Its internal bond strength is lower than that of MDF, making it the most challenging common substrate for fastening. It is highly susceptible to fastener pull-out as the particles crumble around the screw threads. This is made worse by repeated loading, where repeated small movements can quickly degrade the material around the fastener. For this reason, standard wood screws are often inadequate. Specialized fasteners like Confirmat screws or systems that use insert nuts are essential for creating a durable joint in particleboard.

Table 1: Comparative Material Analysis

| Material | Internal Structure | Screw Holding Power (Face/Edge) | Primary Failure Mode | Best Fastening Practices |

| Solid Wood | Anisotropic (Wood Fibers) | Excellent / Good | Splitting along grain | Pilot holes, avoid end-grain fastening, allow for movement |

| Plywood | Layered (Cross-Grained Veneers) | Excellent / Very Good | Minimal; delamination under extreme stress | Standard wood screws, fine-thread screws for Baltic Birch |

| MDF | Uniform (Resin-Bonded Fibers) | Good / Poor | Splitting, thread stripping, pull-out | Coarse-thread screws, pilot holes, avoid edges, use glue |

| Particleboard | Isotropic (Compressed Particles) | Fair / Very Poor | Pull-out, material crumbling | Confirmat screws, insert nuts, cam systems, glue |

An Engineering Look at Fasteners

A fastener is not merely a piece of metal; it is a mechanical device designed to solve an engineering problem. Selecting the right fastener requires understanding the mechanical principle by which it works and matching that principle to the forces it must resist and the material it will inhabit.

Mechanical Fasteners: Screws

The screw is the most common fastener, but not all screws are created equal. Its primary mechanical principle is that of a helical wedge. As it is driven, its threads cut into or displace the substrate, creating immense friction and a strong clamping force that provides high resistance to tension.

- Thread Mechanics: The choice between coarse and fine threads is a critical engineering decision. Coarse threads are designed for soft materials like particleboard and MDF. The larger distance between threads allows them to grip the coarse, weak particles without turning them to dust. Fine threads are for hardwoods and plywood, where their increased surface area provides superior holding power in the dense, strong fibers.

- Head and Drive Types: The head shape distributes the clamping force. A flat head sits flush and is ideal for joinery, while a washer-head or pan-head screw has a large bearing surface that distributes the load over a wider area, preventing pull-through in softer materials and increasing clamping pressure.

- Specialized Cabinet Screws: Confirmat screws are a specific engineering solution for particleboard. They feature a wide, coarse thread for grip, an unthreaded shoulder that prevents jacking, and a large head for clamping force. Washer-head screws, often called “cabinet screws,” are used for installing cabinets, as their built-in washer provides the clamping force needed to pull a cabinet securely to a wall without a separate washer.

Alignment and Shear-Resistance

While screws handle tension well, other fasteners are superior for resisting shear and ensuring precise alignment.

- Dowels: A wood dowel, when properly fitted into a precisely drilled hole, acts as a solid pin that provides exceptional resistance to shear forces. Its primary function is to lock two panels together, preventing any sliding motion. This is why dowels are critical for shelf support and frame alignment. They offer almost no resistance to tension (pull-apart force) on their own and are almost always used in conjunction with glue or another mechanical fastener.

- Biscuits and Dominos: These are floating tenons that fit into corresponding slots. Their primary function is alignment and shear resistance. They create a large surface area for glue, forming a strong, unified joint that is highly resistant to shear. Because they interlock with the panels, they also provide good resistance to torsion or racking forces. Like dowels, they offer negligible tensional strength on their own.

Knock-Down (KD) Hardware

KD hardware allows for the assembly and disassembly of cabinets, but its mechanical principles are just as robust as permanent fasteners when used correctly.

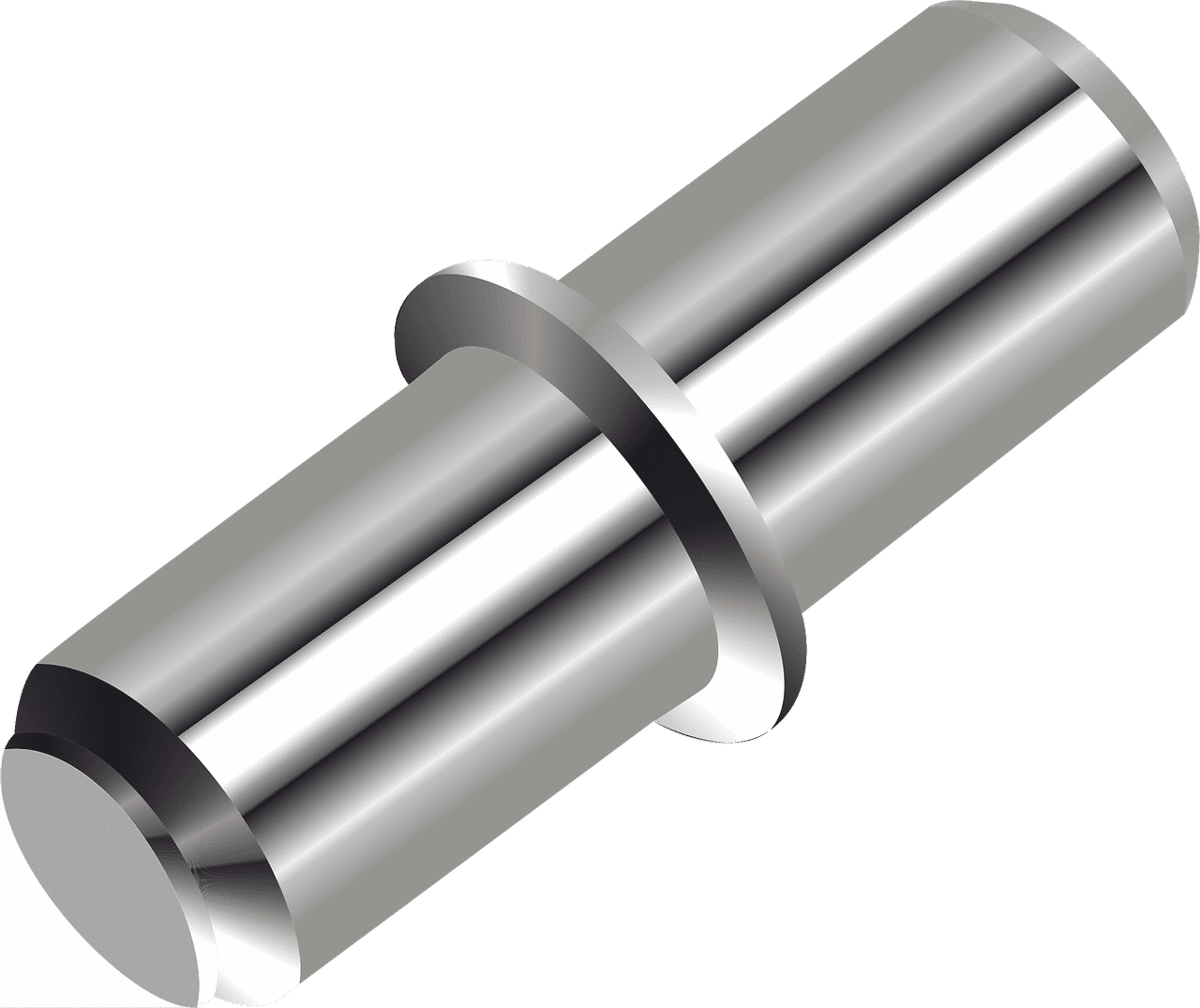

- Cam-Lock Fasteners: This system consists of a metal post that screws into one panel and a cylindrical cam that sits in a hole in the mating panel. As the cam is rotated with a screwdriver, its eccentric internal ramp engages the head of the post, pulling it inward. This mechanism creates a powerful tensional force, clamping the two panels together tightly. Its primary strength is in tension; it offers very little shear resistance. Therefore, it is almost always paired with dowels, which provide the necessary shear strength and alignment.

- Cross Dowels and Barrel Nuts: This is a high-strength mechanical joint. A bolt passes through one panel and threads into a metal cross dowel (or barrel nut) seated in the mating panel. This creates a robust, metal-to-metal connection that is extremely resistant to both tension and shear. It is an excellent choice for high-stress applications like bed frames, workbenches, and structural components in commercial cabinetry.

Table 2: Technical Properties of Cabinet Fasteners

| Fastener Type | Primary Mechanical Principle | Resists | Ideal Substrate(s) | Limitaciones |

| Wood Screw | Helical Wedge (Clamping & Friction) | Tension, Shear | Solid Wood, Plywood | Poor in particleboard edges; can split wood |

| Dowel | Cylindrical Interference Fit | Shear | All | No tensional (pull-apart) strength |

| Cam-Lock | Rotational Eccentric Cam | Tension | MDF, Particleboard | Low shear strength; requires precise boring |

| Confirmat Screw | Wide Thread, Shoulder | Tension, Shear | Particleboard, MDF | Requires specific stepped drill bit; visually intrusive |

| Biscuit | Swelling in Glue-filled Slot | Shear, Alignment | All | Negligible tensional strength; requires specialized tool |

Critical Analysis of Joint Design

The true strength of a cabinet lies not in the fastener itself, but in the design of the joint where the fastener is used. A well-designed joint uses geometry to manage forces, transferring stress from the fastener to the bulk of the material itself. This section combines our understanding of forces, materials, and fasteners by analyzing how they perform within specific joints and how those joints fail.

Integrating Fasteners with Joints

- Butt Joints: A simple butt joint, where one panel edge is fastened to the face of another, is inherently weak. It relies entirely on the fastener’s shear strength and the edge material’s pull-out resistance. In particleboard or MDF, this is a recipe for failure, as the fastener has little material to grip.

- Dado, Rabbet, and Groove Joints: These joints are a significant engineering upgrade. A dado or groove cut into a panel creates a mechanical shoulder that directly supports the mating panel. When a shelf is placed in a dado, the force of gravity is no longer acting as a shear force on the screws. Instead, it becomes a compressive force on the material below the dado. The fastener’s role is reduced to simply keeping the shelf from sliding out. This dramatically increases the joint’s load-bearing capacity and resistance to shear.

- Mortise and Tenon: This is the gold standard of joinery for a reason. The tenon inserts into the mortise, creating massive glue surface area and mechanical interlocking. The shoulders of the tenon bear against the face of the mortised piece, resisting racking. The cheeks of the tenon resist shear and tension. This joint geometry effectively manages tension, compression, and shear forces simultaneously, often before a single mechanical fastener is even added.

A Detailed Look at Failures

In our experience testing cabinet joints to failure, the most common issue we see in particleboard construction is not fastener shear, but substrate pull-out. The fastener is often intact, but it has ripped out a cone-shaped chunk of the weak core material. Understanding these distinct failure modes is the key to preventing them.

- Fastener Pull-Out: This occurs when the fastener’s threads strip the surrounding material, and the joint pulls apart under tension. It is the signature failure of standard screws in low-density substrates like MDF and particleboard edges. Prevention is key: use the correct fastener (e.g., coarse-thread Confirmat screws), use inserts or plugs in high-stress areas, avoid over-torquing screws, and supplement with glue.

- Fastener Shear: This is the physical breaking of the fastener itself under a sliding load. It is common when undersized fasteners are used for heavy loads (e.g., small-diameter shelf pins for a pantry shelf) or when low-quality, brittle screws are used. The prevention strategy is direct: increase the fastener’s diameter to increase its cross-sectional area, use a higher grade of hardened steel, or distribute the load across more fasteners.

- Substrate Fracture: This is when the material around the fastener breaks away, often called tear-out or splitting. It’s common when fastening too close to the edge of a solid wood or MDF panel, or when a pilot hole is omitted or undersized. The expansion force of the screw exceeds the material’s tensile strength. Prevention involves respecting edge distances (a minimum of 1.5 times the fastener diameter is a good rule of thumb) and always using correctly sized pilot holes.

- Joint Fatigue: This is failure from repeated, low-level dynamic loading. A heavily used drawer that feels slightly loose will, over thousands of cycles, slowly work its fasteners loose and degrade the surrounding material until the joint fails completely. The solution is a more robust initial design. Use interlocking joinery like dados in combination with screws, and invest in high-quality drawer slides and hardware that operate smoothly to minimize shock and vibration.

Table 3: Cabinet Fastening Failure Modes & Prevention

| Modo de fallo | Visual Cues | Primary Cause(s) | Engineering-Based Prevention Strategy |

| Fastener Pull-Out | Screw spins freely in its hole; loose joint | Incorrect fastener for substrate; over-torquing; low-density substrate | Use coarse-thread or specialized screws for sheet goods; use insert nuts; use torque-controlled drivers. |

| Fastener Shear | Snapped screw head or dowel; collapsed shelf | Undersized fastener for the load; dynamic overload; low-quality fastener material | Increase fastener diameter and/or grade (e.g., hardened steel); distribute load across more fasteners. |

| Substrate Fracture | Wood or MDF is split, cracked, or crumbling at the joint | Fastener too close to edge; no pilot hole; excessive clamping force from screw head | Maintain proper edge distance (>1.5x fastener diameter); always use correctly sized pilot and clearance holes. |

| Racking / Torsion | Cabinet is out of square; doors do not align | Insufficient diagonal bracing; weak corner joints relying only on butt joints | Install a solid, fully-fastened back panel (3/8″ or thicker); use corner blocks or interlocking joinery. |

Advanced Concepts in Construction

For those building for commercial applications, high-end clients, or simply for maximum longevity, we can apply a few final engineering concepts to elevate construction from good to exceptional.

Understanding the Load Path

The concept of a load path is crucial. It is the path that a force takes as it travels through a structure to the ground or its mounting point. In a cabinet, the weight of a can of soup creates a load path that travels from the can, through the shelf, into the shelf pins, through the cabinet sides, and finally to the floor. A strong design provides a clear, uninterrupted load path. A weak design has interruptions—like a butt joint held only by screws in particleboard—that create stress concentrations and potential failure points. Always visualize how forces will flow through your construction.

Strategic Reinforcement

- Glue as a Structural Element: Modern adhesives like PVA and polyurethane are not just for holding parts together during assembly. When applied correctly to a well-fitting joint, glue creates a unified bond that is often stronger than the wood itself. It distributes stress across the entire joint surface, dramatically reducing the load on the mechanical fasteners.

- Corner Blocks and Nailers: Solid wood blocks, glued and screwed into the corners of a cabinet frame, provide immense reinforcement against racking and torsional forces. They are a simple but incredibly effective way to stiffen a cabinet box. Similarly, nailers—strips of solid wood or plywood integrated into the top and bottom of the cabinet back—provide a solid mounting point for securing the cabinet to the wall, ensuring the installation screws have solid material to bite into.

- The Structural Back Panel: The single biggest improvement one can make to a cabinet’s rigidity is to upgrade the back panel. A thin, 1/8″ back that is merely stapled into a rabbet offers minimal resistance to racking. In contrast, a 1/2″ or 3/4″ plywood back that is fully captured in a dado and then glued and screwed in place transforms the entire cabinet into a rigid, unified structure. It acts as a massive shear panel, making the cabinet virtually immune to torsion.

Benchmarking Against Standards

To add a final layer of authority and validation to these principles, we can look to industry standards. Organizations like the Kitchen Cabinet Manufacturers Association (ANSI/KCMA) and the Business and Institutional Furniture Manufacturers Association (BIFMA) exist to set performance benchmarks for cabinetry and furniture. Their standards are not arbitrary; they are based on rigorous engineering tests that simulate years of use. For example, the KCMA A161.1 standard requires cabinet shelves to support a load of 15 pounds per square foot without excessive deflection or failure. Doors must survive 25,000 swing cycles, and drawers must be opened 25,000 times with a load. Designing with the principles of force, material science, and joint integrity discussed here is precisely how one builds cabinets that can meet and exceed these demanding professional standards.

Conclusion: Combining for Excellence

We have journeyed from the basic physics of cabinet stress to the material science of substrates, the mechanics of fasteners, and the critical analysis of joint design. The ultimate takeaway is this: a durable, high-quality cabinet is not the result of a single “best” fastener or a secret technique. It is the product of a well-engineered system.

True structural integrity is achieved when the design intelligently manages the anticipated forces, the materials are chosen for their specific properties, the fijaciones are selected for their mechanical advantages, and the joint design allows all components to work in harmony. By moving beyond a surface understanding and embracing this technical, engineering-based approach, you gain the ability to not just build a cabinet, but to design a robust structure capable of lasting a lifetime.

- Woodworking and Cabinet Standards – ANSI (American National Standards Institute) https://www.ansi.org/

- Cabinet Manufacturing Standards – KCMA (Kitchen Cabinet Manufacturers Association) https://www.kcma.org/

- Furniture and Cabinet Standards – BIFMA (Business and Institutional Furniture Manufacturers Association) https://www.bifma.org/

- Woodworking Fasteners – Wikipedia https://en.wikipedia.org/wiki/Woodworking

- Fastener Standards – ASTM International https://www.astm.org/

- Wood Engineering and Construction – AWC (American Wood Council) https://www.awc.org/

- Cabinet and Furniture Design – ScienceDirect https://www.sciencedirect.com/topics/engineering/cabinet-design

- Instituto de Fijaciones Industriales https://www.industrial-fasteners.org/

- Woodworking and Cabinet Equipment – Thomasnet https://www.thomasnet.com/

- Materials Engineering – ISO https://www.iso.org/