The Complete Guide to Alloy Steel Screws Raw Material: Buying, Using, and Storing

Introduction

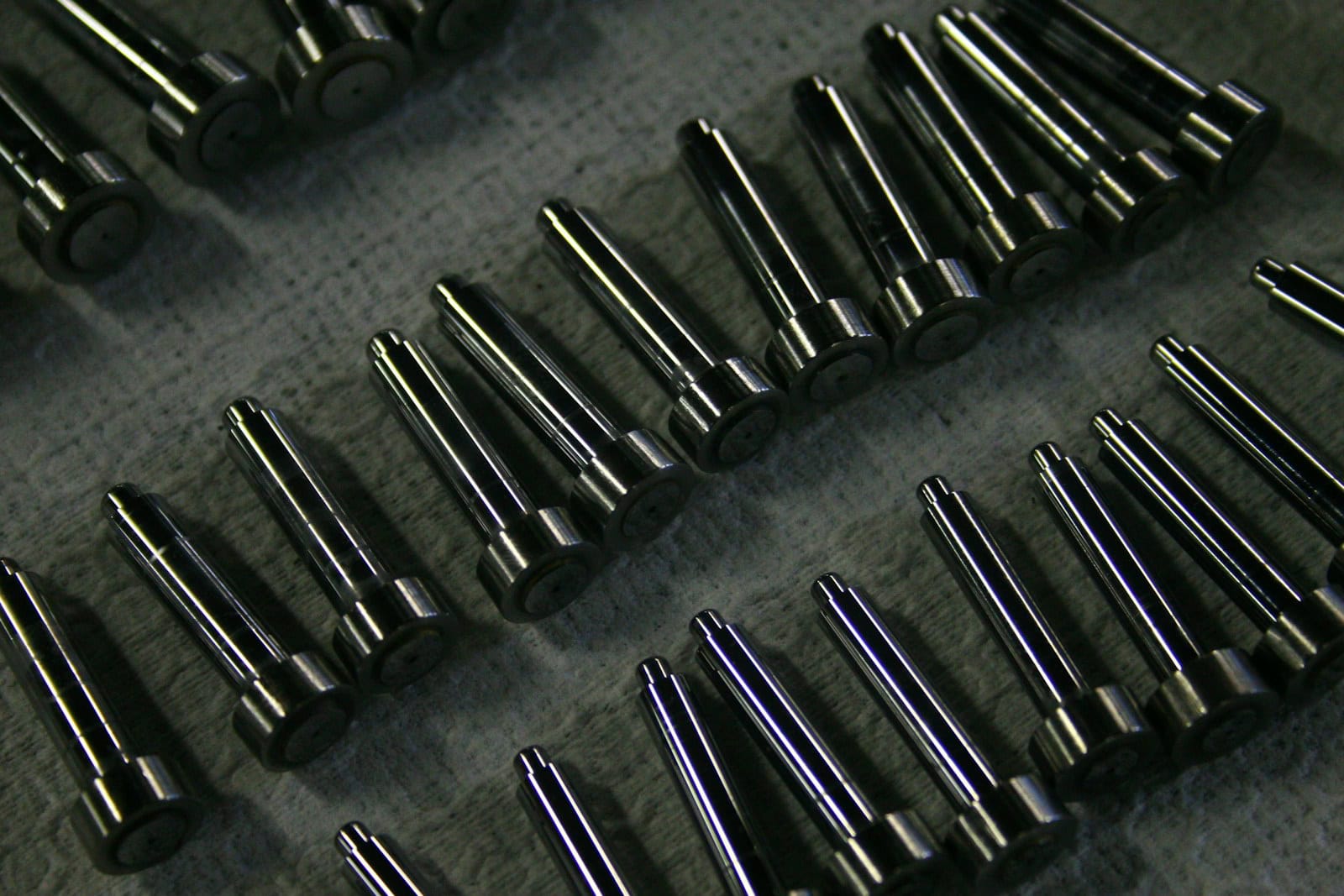

The strength of any building or machine often depends on its smallest parts, like screws. For jobs that require high strength, choosing the right alloy steel screws raw material is not just a small detail—it is the foundation of safety and how well something works. The final strength, toughness, and reliability of a fastener are decided long before it is made; they are built into the chemical makeup and quality of the raw material it comes from. This choice directly affects everything from how much weight a skyscraper can hold to how well an engine bolt can handle repeated stress.

Alloy steel raw materials for screws are special steel types that contain elements beyond carbon, such as chromium, molybdenum, and nickel. These elements are designed to improve properties like strength, toughness, and resistance to wear compared to regular carbon steels. Picking the right type is a critical decision for any engineer or purchasing manager. This guide provides a complete, practical framework for professionals. We will walk you through understanding the types of alloys, making the right choice, navigating the buying process, and using best practices for storage and handling to ensure final product quality.

Understanding Alloy Steel Types

To make smart decisions, one must first understand the basic differences between common materials. Using alloy steel is a deliberate choice made to meet performance needs that standard carbon steel cannot. This section provides the basic technical knowledge needed to tell materials apart and understand their main properties.

Benefits Over Carbon Steel

The decision to choose alloy steel over carbon steel for fasteners is driven by the need for better mechanical properties. While carbon steel works fine for many general uses, it falls short where high stress, changing loads, or extreme temperatures are involved.

- Higher Tensile Strength and Hardness: The main benefit of alloy steel is how it responds to heat treatment. Alloying elements allow the steel to reach much higher tensile strengths and surface hardness through heating and cooling processes, a capability far beyond that of plain carbon steels. This is essential for high-strength fasteners like those in ISO classes 10.9 and 12.9.

- Better Toughness and Fatigue Resistance: Alloy steels, especially those with nickel, show greater toughness, which is the ability to absorb energy and bend without breaking. This is critical in applications with shock or impact loads. They also offer better fatigue resistance, allowing them to withstand repeated cycles of loading and unloading without failure, a key requirement for parts in engines and machinery.

- Better Temperature Performance: Adding elements like molybdenum and chromium improves the steel’s strength at high temperatures (creep resistance). On the other hand, nickel improves toughness and prevents brittleness at low temperatures. This makes alloy steels suitable for a much wider operating range than carbon steels.

Key Alloying Elements

The specific properties of an alloy steel type are determined by the type and percentage of elements added to the iron and carbon base. Each element plays a distinct role in changing the steel’s structure and performance.

- Chromium (Cr): A cornerstone element for hardness. Chromium increases the material’s response to heat treatment, leading to greater strength and wear resistance. In higher amounts, it is the primary element that provides rust resistance in stainless steels, but even in lower amounts in alloy steels, it offers a modest improvement in rust resistance and prevents scaling at high temperatures.

- Molybdenum (Mo): Molybdenum is a powerful agent for increasing hardenability, meaning it allows for successful hardening of larger cross-sections. It also significantly improves strength at high temperatures, making it a critical component in materials used for high-temperature bolting, such as those specified in ASTM A193.

- Nickel (Ni): Nickel is the key element for improving toughness and impact strength, especially at low temperatures. It is vital for applications where fasteners might be subjected to sudden shocks or operate in very cold conditions. Nickel also contributes to hardenability.

- Vanadium (V): Vanadium is used in small quantities to refine the grain structure of the steel. A finer grain structure improves both strength and toughness at the same time. It also increases wear resistance and raises the temperature at which the steel begins to soften.

- Manganese (Mn): While present in almost all steels, manganese is added in higher quantities in alloy steels to improve hardenability and wear resistance. It also counteracts the harmful effects of sulfur, improving the steel’s hot-working properties.

- Boron (B): Added in extremely small amounts, boron has a very large effect on hardenability. Boron-treated steels like 15B41 can achieve high strength levels comparable to more expensive, higher-alloyed steels, making them a cost-effective choice for high-volume production of automotive bolts and screws meeting standards like SAE J429 Grade 8.

Common Screw Steel Types

The industry relies on a set of standard alloy steel types, each offering a unique balance of performance, ease of manufacturing, and cost. Understanding these common types is the first step toward making an appropriate choice. The following table provides a comparison of materials frequently used for manufacturing high-strength screws.

Table 1: Comparison of Common Alloy Steel Raw Materials for Screws

| Grade (AISI/SAE) | Key Alloying Elements | Main Characteristics & Strengths | Utilisations courantes | Relative Cost Index |

| 4140 | Cr, Mo | Excellent strength, toughness, and wear resistance after heat treatment. Versatile and widely available. | High-strength bolts, machine parts, automotive components, structural fasteners. | Moyen |

| 4340 | Ni, Cr, Mo | Superior toughness and strength compared to 4140. Good for larger section sizes. Excellent fatigue resistance. | Aircraft landing gear, high-stress engine bolts, critical structural components. | Haut |

| 8620 | Ni, Cr, Mo | Primarily a carburizing steel. Creates a very hard surface with a tough core. Excellent wear resistance. | Gears, camshafts, specialized wear-resistant fasteners where surface hardness is key. | Medium-High |

| 15B41 (Boron Steel) | B, Mn | Excellent hardenability at a lower cost than traditional alloys. Responds very well to heat treatment. | High-volume automotive bolts and screws (e.g., Grade 8.8, 10.9). | Low-Medium |

The Material Selection Process

Choosing the best raw material is a systematic process, not a guess. It involves a logical evaluation of the application’s demands against the properties and costs of available materials. This process provides a step-by-step guide to help engineers and buyers move from a list of materials to a confident, justifiable decision, preventing both costly over-engineering and dangerous under-specification.

Define Mechanical Requirements

The first and most important step is to quantify the physical demands that will be placed on the screw. These requirements are typically defined by engineering standards and blueprints.

- What tensile strength is required? This is the most common metric for screw strength, often specified by a property class (e.g., ISO 898-1 Class 8.8, 10.9, 12.9) or a grade (e.g., SAE J429 Grade 5, 8). For example, a Class 12.9 screw requires a material capable of reaching a minimum tensile strength of 1220 MPa after heat treatment. This immediately narrows the choice to high-hardenability alloy steels like 4140 or 4340.

- What are the hardness specifications? Hardness, measured in scales like Rockwell C (HRC), is directly related to tensile strength and wear resistance. The target hardness range will dictate the required heat treatment process and influence the choice of material. For instance, a specification requiring through-hardening to 38-42 HRC is well-suited for a grade like 4140.

- Will the screw face shear, tensile, or fatigue loads? While tensile strength is a headline figure, the type of load is crucial. A screw under pure tensile load behaves differently than one under shear stress. For applications involving dynamic or cyclic loads, such as in an engine connecting rod, fatigue resistance is the most critical property. Here, a high-toughness, clean steel like 4340, known for its superior fatigue life, would be the preferred choice over a more general-purpose grade.

Assess Operating Environment

A screw’s performance is inseparable from its environment. Factors like temperature and exposure to corrosive agents can dramatically affect material integrity.

- Temperature: Will the screw be exposed to extreme heat or cold? For high-temperature applications, such as in exhaust manifolds or turbines, materials must resist “creep,” or slow deformation under stress. The molybdenum content in grades like 4140 provides good high-temperature strength. For very cold or low-temperature service, brittleness becomes the primary concern. The nickel content in 4340 significantly improves low-temperature toughness, preventing catastrophic brittle fracture.

- Corrosion: Is exposure to moisture, chemicals, or salt a concern? It is crucial to remember that alloy steels are not stainless steels; they will rust. The selection process must account for this. If the environment is mildly corrosive, the choice of material may be less critical than the choice of a protective coating. However, if the base material must offer some resistance or if a coating could be compromised, this becomes a more significant factor. In highly corrosive environments, a different class of material, such as stainless steel or a nickel-based alloy, may be necessary.

Consider Manufacturing Processes

The raw material must not only meet the final performance criteria but also be suitable for the manufacturing processes used to create the screw.

- Heat Treatment: How will the material respond to heating and cooling? The “hardenability” of the steel is a key consideration. For large-diameter screws, a material with high hardenability, like 4340, is needed to ensure the core of the screw reaches the required hardness. If the design calls for a very hard, wear-resistant surface with a softer, tougher core, a carburizing grade like 8620 is the correct choice, as it is specifically designed for this case-hardening process.

- Formability: Is the screw head cold-formed or hot-forged? Most standard screws are cold-formed from wire coils. The material must have sufficient ductility to be shaped without cracking. Hot forging is used for larger diameters or complex head shapes. The material choice must be compatible with the chosen forming method.

- Coatings: Will a protective coating be applied? Common coatings include zinc plating, zinc flake, or phosphate and oil. The raw material must be compatible with the chemical and thermal processes involved in coating. A critical consideration is hydrogen embrittlement, a phenomenon where hydrogen can be absorbed by high-strength steel during plating processes, leading to brittle failure. Material selection and subsequent baking processes must be carefully managed to reduce this risk.

Cost vs. Performance Analysis

The final step in the selection process is a practical analysis of cost versus performance. This goes beyond simply comparing the price per kilogram of different alloys.

- Initial Cost vs. Lifecycle Cost: A cheaper material like 15B41 might be perfect for a high-volume, cost-sensitive automotive application where the operating conditions are well-defined and controlled. However, using that same material in a critical, high-fatigue application to save on initial cost could lead to early failure, resulting in warranty claims, recalls, and safety incidents—all of which carry a much higher lifecycle cost.

- The “Over-engineering” Trap: Conversely, it is equally important to avoid specifying the highest-performance material when it is not necessary. Choosing 4340 for an application where the strength and toughness of 4140 are more than sufficient is a common mistake. This “over-engineering” adds unnecessary cost to the final product without providing any real benefit in the application. A simple decision matrix can be helpful: for high-fatigue, critical applications where failure is not an option (e.g., aerospace), the high cost of 4340 is justified. For general high-strength industrial machinery, 4140 often provides the best balance of performance and cost.

Sourcing Raw Material

Once the correct grade of alloy steel is selected, the focus shifts to procurement. Sourcing high-quality raw material is as critical as the initial engineering decision. This section provides a practical guide for buyers to navigate the supply chain, vet suppliers, and ensure the material received matches the material specified.

Mills vs. Distributors

The first decision in sourcing is whether to purchase directly from a steel mill or through a distributor or service center.

- Steel Mills: Buying directly from a mill is typically an option only for extremely large quantities, often measured in hundreds of tons per order. This route offers the lowest price per ton but comes with long lead times, large minimum order quantities, and very little flexibility. It is reserved for the largest manufacturers with highly predictable, high-volume demand.

- Distributors/Service Centers: For most screw manufacturers, distributors are the primary source of raw material. They purchase in bulk from various mills and sell in smaller, more manageable quantities (from single bars to a few tons). They offer much shorter lead times, maintain stock of common grades, and can often provide value-added services like cutting to length or precision grinding. A good distributor is more than a vendor; they are a supply chain partner.

How to Check a Supplier

Choosing the right supplier is essential to ensuring consistent quality and a reliable supply chain. A thorough checking process should be a standard operating procedure. A partnership with a poor supplier introduces significant risk into your production process.

Table 2: Essential Supplier Checking List

| Category | Élément de la liste de contrôle | Why It’s Important |

| Quality & Certification | Do they have ISO 9001 or other relevant quality certifications (e.g., AS9100 for aerospace)? | Shows a documented and audited commitment to quality management systems and process control. |

| Can they consistently provide a full Material Test Report (MTR) with every shipment? | This is non-negotiable. The MTR is the primary document for traceability and quality verification. | |

| Expertise & Support | Does their sales or technical team understand your application and material needs? | A partner who understands the difference between 4140 and 4340 can help you solve problems and optimize costs. |

| Do they have experience supplying to your industry (e.g., automotive, construction)? | Industry-specific experience means they understand the relevant standards and quality expectations. | |

| Logistics & Inventory | Do they maintain adequate stock of the grades you need? What are their lead times? | Ensures your production line does not stop due to material shortages. Reliability is key. |

| What is their process for ensuring material traceability and preventing mix-ups in their warehouse? | A strong internal system prevents costly errors like shipping the wrong grade of steel. | |

| Reputation | Can they provide references from other customers in your industry? | Social proof of their reliability, service quality, and ability to deliver on their promises. |

Understanding the MTR

The Material Test Report (MTR), also known as a mill certificate, is the most important quality document you will receive with your raw material. It is a formal record from the steel mill certifying the material’s properties. From an experienced quality control perspective, knowing how to read and interpret this document is a fundamental skill.

- Heat Number: Think of this as the material’s birth certificate. It is a unique code assigned to a specific batch or “heat” of steel produced at the mill. Every process and test result on the MTR is tied directly to this number. This heat number must be traceable from the raw material bar all the way to the finished box of screws. This is the cornerstone of all quality control and any potential failure analysis.

- Chemical Composition: The MTR will list the exact chemical analysis of the heat, showing the weight percentage of carbon, manganese, chromium, molybdenum, and other specified elements. Your first check should be to compare this analysis against the required range for the ordered grade (e.g., for 4140, chromium should typically be between 0.80% and 1.10%). If any element is outside the specification, the material is non-conforming.

- Mechanical Properties: This section reports the results of physical tests performed on samples from the heat. Key values include Tensile Strength (the maximum stress the material can withstand), Yield Strength (the stress at which the material begins to deform permanently), and Elongation (a measure of ductility). As a crucial tip: always cross-reference these reported values with the requirements of the standard (e.g., ASTM A193 B7) that you specified in your purchase order. The MTR might show the material in its “as-rolled” or annealed state, so these properties will change significantly after your own heat treatment process. Understanding this distinction is vital.

Handling and Storing Raw Material

The investment in high-quality alloy steel can be completely wasted if the material is not handled and stored correctly. Proper storage practices are not just about housekeeping; they are a critical quality control step that prevents material degradation before it even enters the production line. Improper storage can ruin even the highest-grade material.

Enemies of Alloy Steel

Once the material arrives at your facility, it faces three main threats: corrosion, contamination, and mechanical damage. A strong storage plan is designed to reduce all three.

- Corrosion (Rust): This is the primary and most obvious enemy. Alloy steel is not stainless. When exposed to humidity, condensation, or direct contact with moisture, it will begin to rust. Surface rust can often be cleaned, but significant pitting can create stress risers that compromise the integrity of the final screw.

- Contamination: Contact with foreign substances can cause significant problems. Oils and greases can interfere with heat treatment, leading to soft spots. Dirt and grit can increase wear on forming dies. Cross-contamination from other metals, such as grinding dust from stainless steel, can embed in the surface and become a localized point for corrosion.

- Mechanical Damage: Raw material in the form of bars or coils is susceptible to damage during transport and handling. Dents, deep scratches, and gouges are not just cosmetic flaws. These imperfections can act as stress concentration points, becoming the origin of a fatigue crack in a finished, high-stress fastener.

Practical Storage Solutions

An effective storage system is simple, organized, and focused on protecting the material.

- Indoor Storage is Non-Negotiable: This is the most important rule. Alloy steel raw material must be stored indoors in a dry, preferably climate-controlled, building. Storing it outside, even temporarily under a tarp, is an invitation for corrosion.

- Keep it Dry and Off the Floor: Material should be stored on proper racking systems or on wooden pallets. Direct contact with a concrete floor should always be avoided, as concrete can absorb moisture from the ground and hold it against the steel, speeding up rust.

- Material Identification: Clear and permanent identification is critical to prevent material mix-ups. Every bar, bundle, or coil must be clearly labeled with its grade, heat number, and diameter. We have seen entire production runs of critical fasteners ruined because a bar of 4140 was mistaken for 4340. Proper, clear labeling on every piece of stock is cheap insurance against catastrophic errors.

- Inventory Management: Implement a First-In, First-Out (FIFO) system. This ensures that older material is used before newer material, minimizing the total time any given piece of stock sits in storage and reducing its overall exposure to potential degradation.

Handling and Storage Do’s and Don’ts

A simple checklist can serve as a quick reference for all personnel involved in receiving, storing, and moving raw material.

Table 3: Raw Material Storage Best Practices

| Do | Don’t |

| DO store material indoors in a dry, climate-controlled area. | DON’T store material outside, even if temporarily covered. |

| DO keep material on racks or pallets, off the concrete floor. | DON’T allow bundles to have direct contact with the ground. |

| DO maintain clear labels with Heat Number and Grade on all stock. | DON’T mix different grades or heat numbers in the same rack without clear separation. |

| DO use a FIFO (First-In, First-Out) inventory system. | DON’T let material sit unprotected and unidentified for long periods. |

| DO handle with care to avoid dents, gouges, and bending. | DON’T drag material across rough surfaces or drop it from a height. |

Conclusion: Smart Decisions for Better Performance

The journey from a raw bar of steel to a high-performance screw is a chain of critical decisions. As we have explored, choosing the right alloy steel screws raw material is a multi-faceted process that requires a careful balance of mechanical requirements, environmental factors, manufacturing considerations, and total cost. It is a decision that lays the groundwork for the safety and reliability of the final assembly.

From understanding the specific role of chromium and molybdenum to reading the detailed information of a Material Test Report and implementing a disciplined storage system, every step is a critical link in the quality chain. A methodical approach to raw material selection, sourcing, and handling is not an operational burden; it is a fundamental pillar of modern quality assurance and risk management. It is the proactive way to ensure that the fasteners you produce will perform as designed, every time. By mastering these principles, you move from simply buying steel to strategically investing in the performance, durability, and ultimate success of every screw your company produces.

Reference Links:

- AISI 4140 Alloy Steel (UNS G41400) – AZoM https://www.azom.com/article.aspx?ArticleID=6769

- 4140 Alloy Steel: Uses, Composition, Properties – Xometry https://www.xometry.com/resources/materials/4140-alloy-steel/

- SAE AISI 4340 Steel Properties, Heat Treatment – The World Material https://www.theworldmaterial.com/astm-sae-aisi-4340-alloy-steel/

- Online Materials Information Resource – MatWeb https://www.matweb.com/

- SAE J429 Specification – Portland Bolt https://www.portlandbolt.com/technical/specifications/sae-j429/

- Fastener & Bolt Specifications – Portland Bolt (All Specifications) https://www.portlandbolt.com/technical/specifications/

- SAE J429: Mechanical and Material Requirements – SAE International https://www.sae.org/standards/content/j429f_197106/

- Decoding ASTM, SAE, & ISO Grade Markings For Steel Fasteners – American Fastener https://www.americanfastener.com/astm-sae-and-iso-grade-markings-for-steel-fasteners/

- Material Properties – Engineering ToolBox https://www.engineeringtoolbox.com/material-properties-t_24.html

- AISI 4130 Steel Material Data Sheet – ASM/MatWeb https://asm.matweb.com/search/SpecificMaterial.asp?bassnum=m4130r