Special Fasteners Processing: A Complete Guide to Making High-Performance Hardware

Special fasteners are specially designed parts that work in tough conditions where regular bolts and screws would break. Unlike ordinary hardware you can buy at any store, these fasteners are used in airplanes, medical equipment, ships, and other important applications where failure could be dangerous. Their special abilities—like working in extreme heat, having incredible strength, or resisting rust—don’t come from the metal alone. Instead, they come from a series of carefully controlled manufacturing steps. Making a special fastener is like a transformation journey. This guide provides a roadmap of that journey, breaking down the key steps that turn raw metal into mission-critical hardware. We will look at the important role of material science, the main manufacturing methods of shaping and cutting, the metal improvement process of heat treatment, the protective coating process, and the final step of thorough quality testing.

The Foundation of Performance

Choosing the right material is the most important first step in Special Fasteners Processing. This choice controls all the manufacturing steps that follow and ultimately determines how well the fastener will perform. The entire process works by combining the natural properties of a metal with the manufacturing methods used to shape and improve it.

How Metal Science Works

Metal science is the field that connects what metals are made of to how they perform mechanically. For special fasteners, properties like tensile strength (how much pulling force they can handle), shear strength (resistance to sideways forces), fatigue life (how long they last under repeated stress), rust resistance, and performance in extreme temperatures are most important. These aren’t random numbers—they directly depend on what elements are in the metal and how its microscopic structure is arranged. Different elements are added to a base metal to achieve specific results. Chromium makes metals more rust-resistant and harder. Molybdenum increases strength at high temperatures. Nickel improves toughness and rust resistance. Vanadium makes the grain structure finer, increasing toughness and shock resistance. The skill in special fastener manufacturing lies in controlling this grain structure through processing to unlock the material’s full potential.

Material Selection Guide

The environment where a fastener will be used determines what material to choose. A bolt for airplane landing gear needs incredible fatigue strength, while a fastener in a chemical reactor needs superior rust resistance. We use a systematic approach to material selection, guided by what the application demands.

Table 1: Material Selection Guide for Special Fasteners

| Classe de matériaux | Specific Alloy Example | Caractéristiques principales | Optimal Applications | Processing Considerations |

| Alliages de titane | Ti-6Al-4V | High strength-to-weight ratio, excellent corrosion resistance. | Aerospace structures, medical implants, marine hardware. | Difficult to machine; requires vacuum heat treatment; susceptible to galling. |

| Superalliages à base de nickel | Inconel 718 | Maintains high strength at extreme temperatures; creep resistant. | Gas turbine engines, combustion sections, nuclear applications. | Extremely difficult to machine; requires specialized solution and aging heat treatments. |

| PH Stainless Steels | 17-4 PH | High strength, good corrosion resistance, hardenable by heat treatment. | Valve parts, gears, chemical processing equipment. | Requires precipitation hardening (aging) after fabrication. |

| Alloy Steels | 4140 / 4340 | High tensile strength, toughness, and fatigue resistance. | High-strength automotive bolts, structural connections, landing gear. | Must be quenched and tempered; requires protective coating for corrosion. |

Design for Easy Manufacturing

A fastener’s design is closely connected to how it’s made. Design for Manufacturability (DFM) is an important engineering principle where the design is optimized for its manufacturing process. For special fasteners, this means thinking about how geometric features will be formed. The radius of a head-to-shank curve, for example, isn’t just a size requirement—it’s a critical feature that affects stress concentration and is best formed by forging. Choosing a thread form, such as a J-form thread with a larger root radius, is a design choice made specifically to improve fatigue life and work well with the thread rolling process. Tight tolerances may require CNC machining instead of forging, affecting cost and mechanical properties. DFM ensures the final design not only works but can also be manufactured in a way that maximizes its performance characteristics.

Processus de fabrication de base

After choosing the material, the raw metal must be shaped into the fastener’s basic form. This is done through two main families of processes: forging and machining. The choice between them is a fundamental engineering decision based on material, shape, production volume, and, most importantly, the required mechanical properties.

Forging Processes

Forging is a manufacturing process that involves shaping metal using localized squeezing forces. It is a forming process, not a cutting one, which has major effects on the material’s internal structure.

Cold Forging

In cold forging, also known as cold heading, wire or bar stock is shaped at room temperature through a series of dies. The material is forced to flow into the die cavity, forming the head and shank. Because the process is done below the material’s recrystallization temperature, it causes work hardening, which significantly increases the fastener’s tensile strength and hardness. The benefits are numerous: exceptional size accuracy, a smooth surface finish that often needs no additional operations, and high production speeds. However, the high forces required limit the process to more bendable materials and less complex shapes.

Forgeage à chaud

Hot forging is performed above the material’s recrystallization temperature. Heating the metal makes it more bendable and shapeable, allowing for the formation of more complex shapes and the use of high-strength alloys that cannot be cold-formed. The single greatest advantage of hot forging, especially for critical fasteners, is its effect on the grain structure. Instead of cutting through the material’s grain, hot forging forces the grain to flow and follow the contour of the fastener, particularly at the critical head-to-shank curve. This continuous grain flow eliminates the internal stress points found in machined parts and drastically increases fatigue strength and shear resistance. This is the main reason hot forging is required for many critical aerospace and engine bolts where repeated loading is a major concern.

Machining Processes

Machining is a subtractive process where material is removed from a larger piece of stock to achieve the desired shape. It offers a different set of advantages and is essential for certain types of special fasteners.

CNC Turning and Milling

Computer Numerical Control (CNC) turning and milling use computer-controlled cutting tools to precisely remove material from bar stock. Turning is used for cylindrical features like the shank and threads, while milling creates complex head shapes or features. CNC machining is the ideal method for producing fasteners with extremely complex shapes that are impossible to forge. It is also the most economical choice for small production runs or prototypes, as it doesn’t require the expensive custom tooling associated with forging. Furthermore, some high-performance materials, like certain nickel-based superalloys, are so difficult to work that machining is the only viable option.

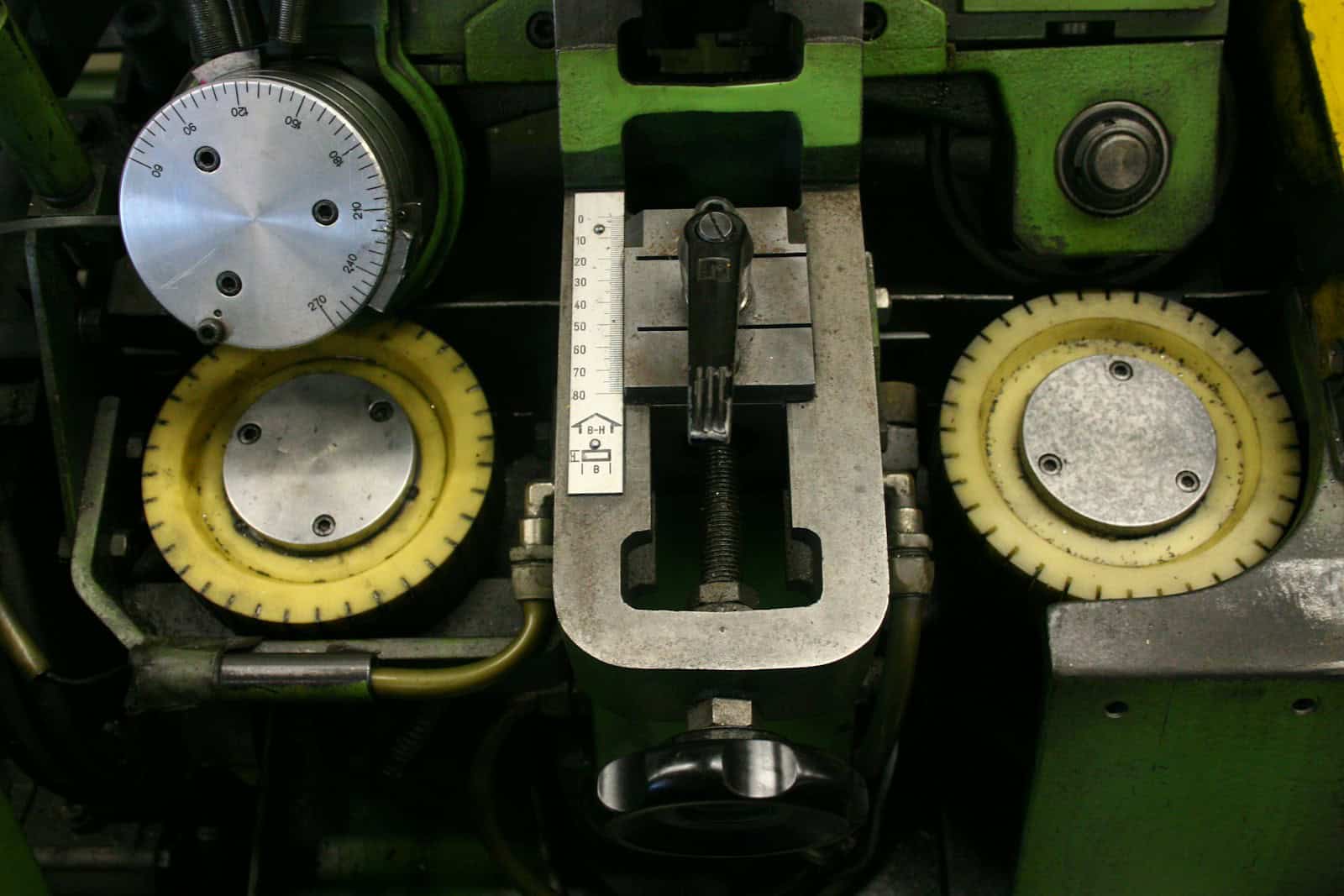

Thread Rolling vs. Cutting

The method used to create threads is one of the most critical steps in Special Fasteners Processing. A thread can be cut or rolled, and the difference in performance is huge. Thread cutting is a machining process where a tool removes material to form the thread profile. This action cuts directly through the material’s grain structure, creating sharp roots and potential stress points where fatigue cracks can start.

In contrast, thread rolling is a cold-forming process. The fastener blank is rolled between hardened dies that plastically deform the surface, pressing the thread profile into the material. This process doesn’t remove material; it moves it. The grain structure isn’t cut but is forced to flow along the contour of the thread. This creates a denser, work-hardened surface and, most importantly, creates compressive residual stresses at the thread root. These compressive stresses work to counteract tensile loads experienced in service, significantly improving the fastener’s fatigue life. For any application involving vibration or repeated loads, rolled threads are vastly superior to cut threads.

Comparing the Processes

Choosing between forging and machining involves a trade-off between mechanical properties, cost, and geometric capability. We select the process that delivers the optimal balance for the specific application.

Table 2: Technical Comparison of Primary Manufacturing Processes

| Paramètres | Cold Forging | Forgeage à chaud | Usinage CNC |

| Mechanical Properties | Good (work hardened) | Excellent (optimized grain flow) | Good (dependent on raw material) |

| Résistance à la fatigue | Très bon | Excellent | Fair (can be improved with thread rolling) |

| Déchets matériels | Minimal | Faible à moyen | Haut |

| Vitesse de production | Très élevé | Haut | Faible à moyen |

| Coût de l'outillage | Haut | Haut | Faible |

| Ideal Batch Size | Large | Medium to Large | Small to Medium |

| Complexité géométrique | Limitée | Moyen | Très élevé |

Improving Mechanical Properties

A fastener that has been forged or machined is only a shaped piece of metal; it doesn’t yet have the final properties required for its application. Heat treatment is the critical, transformative stage where we scientifically control the alloy’s microstructure to achieve the desired hardness, strength, and toughness.

Heat Treatment Purpose

The purpose of heat treatment is to control phase transformations within the metal’s crystalline structure. By carefully heating and cooling an alloy through specific temperature cycles, we can refine its grain size, dissolve or precipitate alloying elements, and relieve internal stresses created during manufacturing. This process is like baking; the ingredients (alloying elements) have been mixed, and the shape has been formed, but it is the controlled application of heat that creates the final, desired product. Without proper heat treatment, a high-strength alloy is no stronger than common steel.

Key Heat Treatments

Different alloy systems require distinct heat treatment protocols to unlock their potential. The process must be precisely matched to the material.

- *Quenching and Tempering:* This is the classic two-step process for carbon and alloy steels like 4140 and 4340. The fastener is heated to a high temperature (austenitizing), then rapidly cooled or “quenched” in a medium like oil or water. This creates a very hard but brittle martensitic structure. The subsequent tempering step involves reheating the part to a lower temperature, which reduces some of the hardness but significantly increases its toughness, achieving a superior balance of mechanical properties.

- *Solution Treatment and Aging:* This process is essential for precipitation-hardenable (PH) alloys, including Inconel 718 and 17-4 PH stainless steel. First, a solution treatment heats the fastener to a high temperature to dissolve the strengthening elements into a uniform solid solution. After quenching, the material is relatively soft. The second step, aging (or precipitation hardening), involves reheating the part to a moderate temperature for an extended period. This causes the dissolved elements to precipitate out of the solution as microscopic, strength-giving particles within the metal’s grain structure, dramatically increasing its strength and hardness.

- *Annealing:* Annealing is a heat treatment that changes the microstructure of a material to change its mechanical or electrical properties. Typically, in steels, annealing is used to reduce hardness, increase bendability and help eliminate internal stresses. This process is often performed between manufacturing steps, for example, to soften a part after forging to make it easier to machine.

The Role of Atmosphere

For many high-performance alloys, what surrounds the fastener during heat treatment is as important as the temperature itself. Reactive alloys like titanium and certain superalloys will readily react with oxygen at high temperatures, forming a brittle oxide layer that can compromise the part’s integrity—a phenomenon known as oxygen embrittlement. To prevent this, heat treatment for these materials must be conducted in a controlled atmosphere. This is typically achieved in a vacuum furnace, where the air is pumped out, or in a furnace filled with an inert gas like Argon. This level of control is non-negotiable for ensuring the metallurgical quality of critical aerospace and medical components.

Surface Engineering

The final stages of Special Fasteners Processing focus on the surface. Surface engineering encompasses a range of treatments designed to protect the fastener from its operational environment and enhance its functional characteristics, such as lubricity or wear resistance. A perfect core material can still fail if its surface degrades.

Coatings and Platings Guide

Coatings and platings are applied for a variety of technical reasons, with rust protection being the most common. The choice of treatment is driven by the base material, the service environment, and galvanic compatibility with mating components. Following industry standards like ASTM or AMS ensures that the coating process is controlled and the result is repeatable.

Table 3: Common Traitements de surface and Their Technical Functions

| Traitement / Revêtement | Primary Function | Common Standard (Example) | Typical Fastener Application |

| Cadmium Plating | Sacrificial corrosion protection; excellent lubricity. | AMS-QQ-P-416 | Aerospace structural fasteners (use is declining due to environmental concerns). |

| Passivation | Enhances natural corrosion resistance of stainless steels. | ASTM A967 | All stainless steel fasteners, especially for medical and food-grade use. |

| Silver Plating | Anti-galling and conductivity at high temperatures. | AMS 2410 | High-temperature engine nuts and turbine bolts. |

| Dry Film Lubricant (MoS₂, Graphite) | Reduces friction and prevents galling during installation. | AS5272 | Threaded fasteners in titanium or stainless steel to ensure proper preload. |

| Phosphate & Oil | Mild corrosion resistance and anti-galling for steel. | MIL-DTL-16232 | Automotive and industrial steel fasteners. |

Advanced Surface Modification

Not all surface treatments are additive coatings. Some of the most effective methods modify the properties of the base material itself.

Shot peening is a prime example. It is a cold-working process where the surface of the fastener is bombarded with small spherical media (shot). Each impact acts like a tiny peening hammer, creating a small indentation. This plastic deformation creates a layer of high-magnitude compressive residual stress at and just below the surface. Because fatigue cracks cannot start or spread in a compressive environment, this layer acts as a powerful barrier against fatigue failure. Shot peening is not a coating; it is an integral change to the part’s surface properties. It is a required process for the threads and curves of many dynamically loaded aerospace components, as it can increase fatigue life by ten times or more.

Process in Action

To bring these concepts together, we can walk through the manufacturing sequence of a real-world special fastener. This demonstrates how each processing step is a deliberate and interconnected part of achieving the final engineering requirements.

Case Study: A Turbine Bolt

- The Challenge: A fastener for a jet engine turbine section, specifically an Inconel 718 bolt. It must maintain extreme strength at operating temperatures up to 650°C (1200°F) while resisting creep and high-cycle fatigue from engine vibration.

- The Process Flow:

- Material Certification: The process begins with the receipt of certified Inconel 718 bar stock. We verify that the material’s chemical composition and metallurgical properties meet the stringent aerospace specification via its accompanying test reports.

- Hot Forging: A blank is cut from the bar and heated above its recrystallization temperature. The head is then hot-forged in a press. This is done specifically to create an optimal, continuous grain flow from the shank into the head, maximizing shear and fatigue strength at this critical junction.

- Solution Treatment: After forging, the blank is subjected to a solution heat treatment. It is heated to a high temperature (approx. 955°C / 1750°F) to dissolve the strengthening phases (gamma prime and double prime) into a solid solution, preparing the material for hardening.

- Machining: The solution-treated blank is now relatively soft and can be machined. The shank is turned to the precise pre-roll diameter required for the threading operation.

- Roulage du fil : The threads are cold-rolled, not cut. This critical step plastically deforms the shank material, creating strong, fatigue-resistant threads with beneficial compressive residual stresses at their roots.

- Precipitation Aging: The fully formed fastener undergoes a two-stage aging heat treatment. It is held at a specific intermediate temperature (e.g., 720°C / 1325°F) and then at a lower temperature (e.g., 620°C / 1150°F). This carefully controlled cycle causes the strengthening phases to precipitate out of the material’s matrix, developing the alloy’s final high-temperature strength and creep resistance.

- Surface Treatment: To prevent galling (a form of wear caused by adhesion between sliding surfaces) during high-torque assembly into the engine, the threads are silver-plated according to a specification like AMS 2410.

- Final Inspection: The finished bolt undergoes 100% Non-Destructive Testing. This includes Dye Penetrant Inspection to check for surface cracks and potentially Ultrasonic Testing for internal integrity. Every dimension is verified before the part is certified for use.

The Final Gate

Quality assurance is not a single step but a philosophy integrated throughout the entire Special Fasteners Processing sequence. It is the final gate that ensures every component is free from defects and meets all engineering specifications before it can be used in a critical application.

A Multi-Layered Approach

We don’t rely on a final inspection alone to catch defects. Quality is built into the process. In-process checks are performed after key stages like forging, heat treatment, and machining. This ensures that any deviation is caught early, preventing waste and guaranteeing that only conforming parts move to the next stage. This layered approach to quality is fundamental to the zero-defect standard required for special fasteners.

Essential Inspection Methods

A combination of inspection techniques is used to validate the integrity and conformity of the finished fasteners.

- Non-Destructive Testing (NDT): These methods are used to inspect every single part for flaws without damaging it.

- *Magnetic Particle Inspection (MPI):* Used for ferromagnetic materials like alloy steels, this method reveals surface and near-surface flaws like cracks by applying a magnetic field and iron particles.

- *Dye Penetrant Inspection (DPI):* Used for non-ferrous materials like titanium and Inconel, a colored dye is applied that seeps into any surface-breaking cracks, making them visible to an inspector.

- *Ultrasonic Testing (UT):* High-frequency sound waves are sent through the material. Echoes from internal defects like voids or inclusions are detected, allowing for the inspection of the part’s internal structure.

- Destructive Testing: To validate the mechanical properties of a production lot, representative samples are tested to failure. These tests include tensile tests to verify ultimate strength and shear tests to confirm shear strength, ensuring the heat treatment and forming processes were successful.

- Dimensional & Visual Inspection: Every critical dimension is verified using advanced tools like Coordinate Measuring Machines (CMMs) and optical comparators. Visual inspection under magnification is also performed to check for any surface imperfections.

A Synthesis of Precision

The processing of special fasteners is a holistic discipline. It is a scientifically controlled and interdependent sequence where the success of each step relies on the one before it. The journey from a certified raw alloy to a finished, inspected component is a testament to the synthesis of metallurgy, mechanical engineering, and rigorous quality control. The critical path—Material Science → Forming/Machining → Heat Treatment → Surface Engineering → Quality Assurance—is the blueprint for creating performance and reliability. The integrity of our most advanced technologies, from deep-space probes to life-saving medical devices, often rests on the engineered perfection of these small but critical components, forged and refined through these precise technical principles.

- ASTM International - Normes et essais de fixations https://www.astm.org/

- SAE International – Aerospace Fastener Standards https://www.sae.org/

- Institut des fixations industrielles (IFI) https://www.indfast.org/

- ASM International – Materials & Heat Treatment https://www.asminternational.org/

- ISO - Organisation internationale de normalisation https://www.iso.org/

- ASME - Société américaine des ingénieurs en mécanique https://www.asme.org/

- Forging Industry Association (FIA) https://www.forging.org/

- NIST - Institut national des normes et de la technologie https://www.nist.gov/

- Aerospace Industries Association (AIA) https://www.aia-aerospace.org/

- ANSI - American National Standards Institute (Institut national américain de normalisation) https://www.ansi.org/