プロジェクトに適した三角ボルトの選び方の基本ガイド

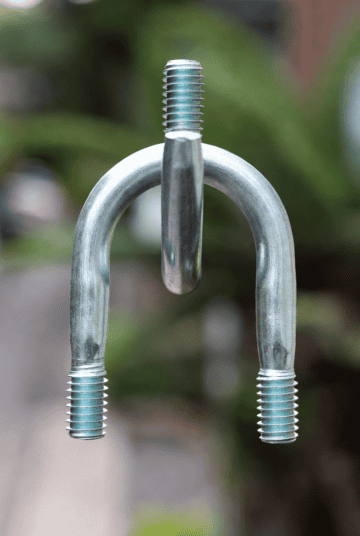

三角ボルトの紹介

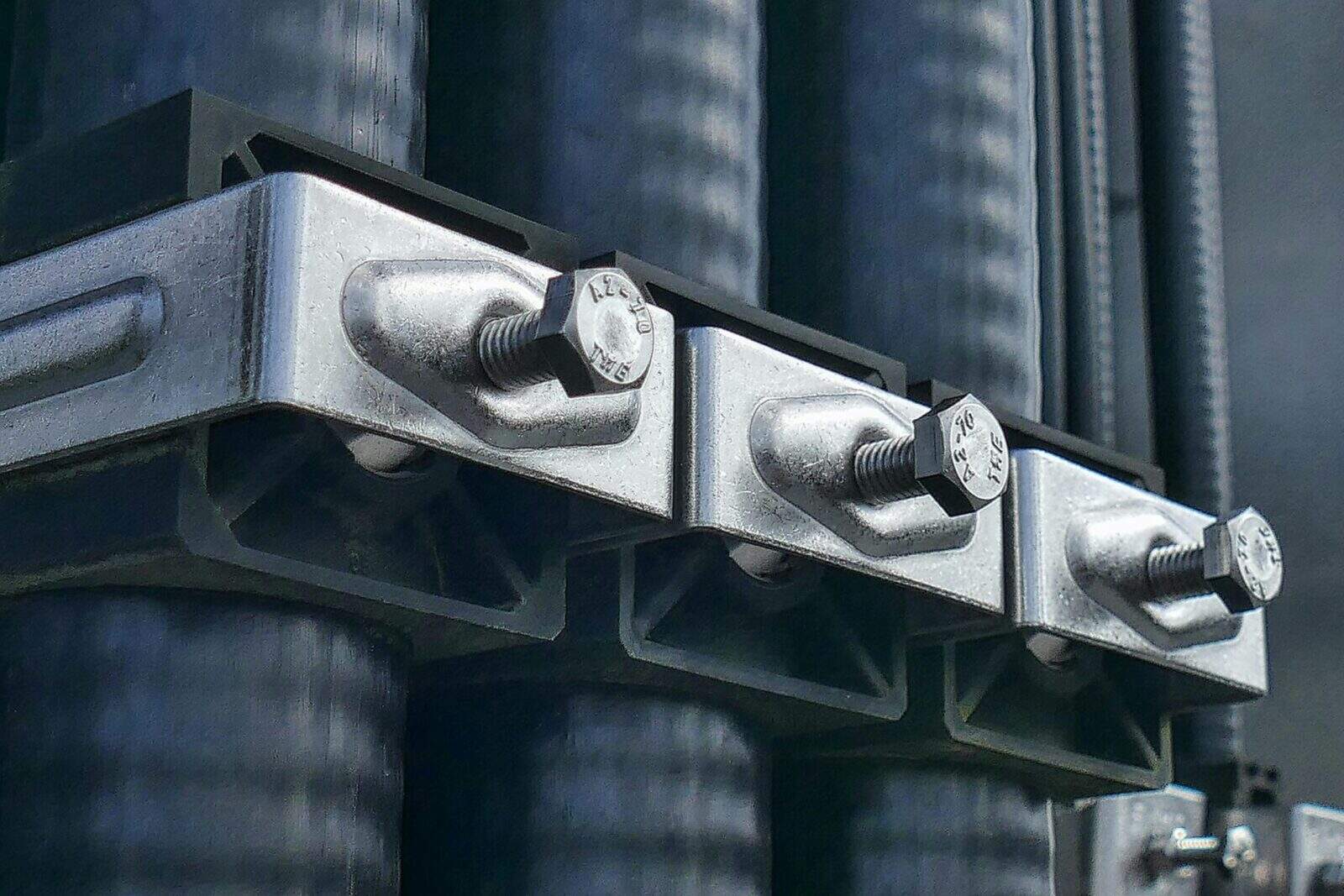

- 三角ボルトは、物を固定するために使用されるファスナーの一種で、高い安全性と安定性を提供します。

- これらは、建設や製造などの産業用途で一般的に使用され、機器を保護し、安全な運用を確保します。

- これらのボルトの独特な三角形の形状は、改ざんに対して耐性があり、チャネル用途での確実なフィット感を提供します。

- 三角ボルトを探す際は、必要な数量と品質を考慮し、最良の結果を得るようにしてください。

- 三角ボルトとその用途について明確に理解することは、情報に基づいた購入決定を行うために不可欠です。

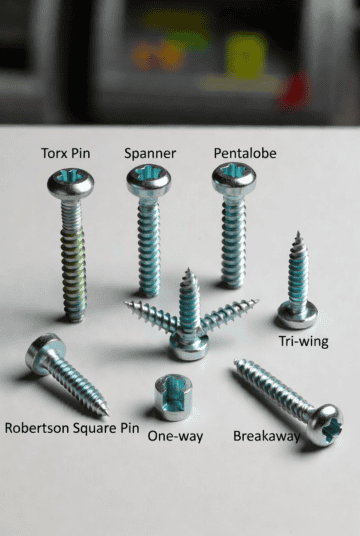

ファスナーの種類

- 三角ボルトを含むさまざまな種類のファスナーが利用可能であり、ねじやその他の特殊なボルトもあります。

- 各タイプのファスナーには独自の特徴と用途があり、プロジェクトに適したものを選ぶことが重要です。

- 三角ボルトは、産業現場など高いセキュリティが求められる用途に特に有用です。

- 三角ボルトの形状と機能は、建設から自動車修理まで多くのプロジェクトに理想的な選択肢となります。

- プロジェクトの具体的なニーズを考慮することで、最適なファスナーの種類を選択できます。

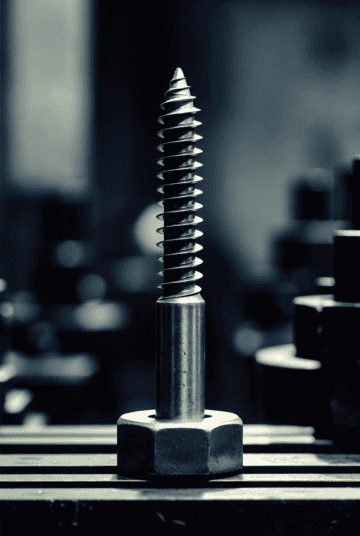

材料と耐久性

- 三角ボルトは、鋼やステンレス鋼などのさまざまな材料で提供されており、 ステンレス 鋼は、異なる用途や環境に適しています。

- 使用される材料のグレードは、耐久性と性能に影響を与え、高グレードはより高い強度と耐腐食性を提供します。

- 三角ボルトを選ぶ際は、さまざまな材料のコストと利点を考慮し、コストパフォーマンスの良い選択をしてください。

- 三角ボルトの耐久性は、また品質にも依存します。 製造工程 彼らのデザインにおける細部への注意。

- 高品質の三角ボルトを選択することで、安全で長持ちする接続を確保できます。

測定とサイズ設定

- 正確な測定とサイズ設定は、三角ボルトを使用する際に適切なフィット感と安全な接続を確保するために重要です。

- ボルトのサイズと寸法、および使用される材料の特性を考慮して、互換性の問題を避けてください。

- ボルトのチャネルとねじ径は、損傷や故障を防ぐために適用に合わせて慎重に一致させる必要があります。

- データや検索ツールを活用することで、プロジェクトに適したサイズとタイプの三角ボルトを見つけることができます。

- 時間をかけて慎重に測定し、適切なボルトを選択することで、 高額な ミスを避け、成功するプロジェクトを実現できます。

セキュリティ機能

- 三角ボルトは、改ざん防止設計や安全ロック機構など、多様なセキュリティ機能を提供します。

- これらの機能により、産業や政府の設定など、セキュリティが最優先される用途に最適です。

- これらのボルトの独特な三角形の形状は、不正アクセスや取り外しに対する追加の保護層を提供します。

- 高度なセキュリティ機能を備えた三角ボルトを選ぶことで、機器や資産を盗難や損傷から守ることができます。

- プロジェクトの具体的なセキュリティニーズを考慮し、それらの要件を満たすか超えるボルトを選択してください。

産業用途

- 三角ボルトは、建設、製造、自動車修理などの産業用途で広く使用されています。

- 特に高いセキュリティと安定性が求められる重機や設備などの状況で役立ちます。

- 三角ボルトの耐久性と強度は、過酷な環境や頻繁な使用に耐えることができるため、産業環境に理想的です。

- 産業用途で三角ボルトを使用することで、仕事の要求に耐える安全で信頼性の高い接続を確保できます。

- 産業プロジェクトの具体的なニーズを考慮し、それらの要件を満たすように設計された三角ボルトを選択してください。

取り付けと取り外し

- 三角ボルトの取り付けと取り外しには、細心の注意と適切な工具が必要です。

- 誤った工具や技術を使用すると、ボルトや周囲の材料を損傷し、修理や交換に高額な費用がかかる可能性があります。

- プロジェクトに適した三角ボルトを選ぶ際には、取り付けと取り外しに必要な時間と労力を考慮してください。

- 安全で適切な接続を確保するために、メーカーの指示やガイドラインに従うことが不可欠です。

- 時間をかけて慎重に三角ボルトを取り付け・取り外しすることで、成功したプロジェクトを実現し、潜在的な問題を避けることができます。

プロジェクト計画

- 三角ボルトを使用するプロジェクトを計画する際には、必要なボルトの数量と品質、また異なる材料やサイズのコストと利点を考慮してください。

- プロジェクトの要件を明確に理解し、それらのニーズを満たすか超えるボルトを選択してください。

- データや検索ツールを活用して、プロジェクトに適した三角ボルトを見つけ、レビューや商品情報を確認して情報に基づいた意思決定を行ってください。

- オンラインで三角ボルトを購入する際には、カートやチェックアウトのプロセスを考慮し、安全で便利な支払いオプションを提供する販売者を選んでください。

- プロジェクトを慎重に計画し、適切な三角ボルトを選択することで、成功とストレスのない体験を確保できます。

購入とメンテナンス

- 三角ボルトを購入する際には、商品情報や他の顧客のレビューを参考にして、高品質な製品を手に入れていることを確認してください。

- さまざまなサイズや材料を取り扱い、競争力のある価格と便利な配送オプションを提供する販売者を探してください。

- 三角ボルトのメンテナンスと管理は、その耐久性と性能を維持するために重要です。

- 定期的にボルトを点検・清掃し、腐食や損傷を防ぎ、異なるメンテナンススケジュールのコストと利点を考慮してください。

- 適切に三角ボルトをメンテナンスすることで、長期間にわたり良好な性能と安全な接続を維持できます。

結論

- 結論として、プロジェクトに適した三角ボルトを選ぶには、ファスナーの種類、材料、サイズなどいくつかの要素を慎重に考慮する必要があります。

- 時間をかけて調査し、適切な三角ボルトを選択することで、安全で成功したプロジェクトを実現できます。

- オンラインで入手可能な情報やデータを参考にし、レビューや商品情報を読み、情報に基づいた意思決定を行ってください。

- 販売者が提供する連絡先情報を使用して質問をし、商品の詳細についてさらに情報を得てください。

- これらのヒントとガイドラインに従うことで、あなたのプロジェクトに適した三角ボルトを見つけ、成功を確実にすることができます。

一般的な用途と産業

三角ボルトは、その独特なデザインとセキュリティ機能により、さまざまな業界で広く使用されています。建設現場では、構造部品を固定するために頻繁に使用されており、フレームやチャネルアセンブリの安定性と不正侵入防止に役立っています。製造施設では、機械や設備を保護するために三角ボルトを使用し、運用の安全性を確保し、不正アクセスを防止しています。

自動車産業は三角形を使用します 重要な箇所で確実に固定する必要があるボルト 振動や過酷な条件に耐えることができる。さらに、これらのボルトはユーティリティや通信分野で一般的に使用されており、屋外環境で機器を固定するために使用されており、耐腐食性の材料の恩恵を受けている。

彼らの耐タンパー設計により、三角ボルトは街灯、看板、公共交通システムなどの公共インフラプロジェクトに最適です。安全性と耐久性が最優先される場所です。全体として、三角ボルトの多用途性と保護特性は、信頼性と安全性が求められるあらゆる用途で好まれる選択肢となっています。 締結ソリューション.

将来の動向

技術と産業の需要が進化するにつれて、三角ボルトは新しい材料や製造技術とともに発展していくことが期待されます。耐腐食性コーティングや高強度合金の革新により、これらのファスナーの耐久性と寿命が向上し、特に過酷な環境での性能が改善されるでしょう。

スマート センサーを組み込んだボルト監視用締結ソリューション 緊張とセキュリティの状態が浮上しており、リアルタイムのメンテナンスを可能にし、故障のリスクを低減します。このデータと接続性の統合は、産業用途におけるモノのインターネット(IoT)の拡大傾向に沿ったものです。

持続可能性も重要な要素となっており、メーカーは環境への影響を減らすためにエコフレンドリーな素材や生産方法を模索しています。さらに、特定のプロジェクト要件に合わせたカスタマイズされた三角ボルトの需要が高まっており、3Dプリンティングや精密工学の進歩によって促進されています。

これらの将来のトレンドについて情報を得ることで、専門家は現在のニーズを満たすだけでなく、明日のプロジェクトの課題も予測できる三角ボルトを選択することができます。

一般的な問題とトラブルシューティング

頑丈な設計にもかかわらず、三角ボルトは取り付け、使用、取り外しの際に時折問題を引き起こすことがあります。これらの一般的な問題とその対処方法を理解することで、プロジェクトの安全性と信頼性を維持することができます。

- 取り付けや取り外しの難しさ

三角ボルトには、その独特な三角形の頭に合う専用の工具が必要です。誤った工具を使用すると、ねじ山を傷つけることがあります。 ボルトヘッド または周囲の材料を損傷することがあります。確実に固定し損傷を避けるために、適切な三角形のキーレンチまたはドライバーを必ず使用してください。 - ボルトのなめりやカムアウト

三角頭のデザインは他の締結具と比べてカムアウトを減らしますが、不適切な工具の使用や過度のトルクはまだ剥がれの原因となることがあります。一定で適度なトルクをかけ、過度な締め付けを避けて損傷を防いでください。 - 腐食と錆

過酷な環境にさらされると腐食を引き起こす可能性があり、特にボルトがステンレス鋼のような耐腐食性材料で作られていない場合は注意が必要です。定期的な点検とメンテナンス(清掃や保護コーティングの塗布を含む)により、ボルトの寿命を延ばすことができます。 - 不適切なサイズまたはフィット

チャネルやねじのサイズに合わないボルトを使用すると、固定が不安定になったり、損傷を引き起こす可能性があります。購入前と取り付け前に慎重に測定し、ボルトの仕様を確認してください。 - 交換用ボルトの入手が困難

特殊な設計のため、三角形の ボルトは標準のファスナーほど入手しやすくない場合があります事前に計画を立て、信頼できる供給業者から十分な数量を購入することで、プロジェクトの遅延を防ぐことができます。

これらの一般的な問題に積極的に対処することで、三角形のボルトが効果的に機能し、プロジェクトに必要な安全性と安定性を提供できるようになります。