プロジェクトに適したネジを選ぶための重要なガイド

ねじの種類の紹介

- 木ねじはほとんどの家庭修理プロジェクトに適しており、耐腐食性と強力な保持力を提供します。

- 機械ねじは金属やプラスチックの組み立てによく使用され、信頼できる接続と締結力を提供します。

- 金属用ねじは、金属部品を固定するために設計されており、取り付け時にねじ山を形成してしっかりと固定します。

- ラグボルト(ラグスクリューとも呼ばれる)は、木材やれんがに対して使用される高強度の締結具であり、優れた固定力を提供します。

- 六角キャップスクリューやセルフタッピングスクリューなど、さまざまな種類のネジを理解することは、プロジェクトに適したネジを選ぶために非常に重要です。

ねじの材料とコーティング

- ネジは鋼、真鍮、亜鉛などさまざまな素材から作ることができ、それぞれに独自の利点と耐腐食性があります。

- 亜鉛やニッケルのようなコーティングは、ねじに施すことで耐腐食性を高め、耐久性を向上させることができます。

- 木材 ネジは一般的に強度のために鋼で作られていますしかし、耐腐食性を高めるために真鍮、ニッケル、ブロンズ、銅からも作ることができます。

- の選択である。 ねじの素材 そしてコーティングは、特定のプロジェクトの要件や環境条件に依存します。

- さらに、ネジはさびに強いコーティングなど、さまざまな用途に合わせて異なるコーティングを施して製造することもできます。

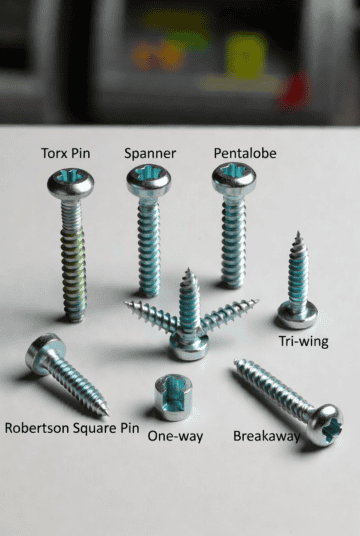

ねじ頭の種類とデザイン

- ネジの頭部は重要な部品であり、フラットヘッド、ラウンドヘッド、プラスドライバー頭など、さまざまな種類があります。

- ねじ頭の種類の選択は、特定の用途や利用可能な工具(ドライバーやレンチなど)によって異なります。

- 一部のネジ頭、例えばトルクス頭は、より高いセキュリティと改ざんに対する耐性を提供します。

- 皿頭ねじは頭部が表面と同じ高さになっており、滑らかな仕上がりと見た目の向上を実現します。

- スロット付きのネジは頭部に一つの溝があり、ドライバーで簡単に取り付けることができます。

機械ねじと用途

- 機械ねじはナットやタップ穴とともに使用されるように設計されており、確実で信頼性の高い接続を提供します。

- これらは機械や電子機器によく使用されており、高い精度と締結力を発揮します。

- 機械ねじは金属やプラスチックなどさまざまな材料に使用でき、直径や長さも異なる種類があります。

- ねじのピッチと直径は、特定の用途に適しているかどうかを判断する上で重要な要素です。

- さらに、機械ねじはボルトやナットなど他のファスナーと併用して、確実で信頼性の高い組み立てを行うことができます。

ボルトとネジのサイズ

- ネジやボルトはインチまたはミリメートルで測定されるさまざまなサイズがあり、通常は直径と長さで指定されます。

- の選択である。 ネジやボルトのサイズは特定の用途に依存します および必要な締結力のレベルによります。

- 安全で信頼性の高い接続を確保するためには、適切なサイズのネジやボルトを選ぶことが不可欠です。

- また、ネジやボルトのねじピッチと直径は、その用途に適しているかどうかを判断する上で重要な要素です。

- 利用可能なさまざまなサイズと種類のネジやボルトを理解することで、情報に基づいた意思決定を行い、プロジェクトに最適なファスナーを選ぶことができます。

結論と最終的な考慮事項

- プロジェクトに適したネジを選ぶには、材料の種類、必要な締結力、環境条件などいくつかの要素を慎重に考慮する必要があります。

- 木ネジ、機械ねじ、板金用ネジなど、さまざまな種類のネジを理解することは、情報に基づいた意思決定を行う上で非常に重要です。

- また、耐腐食性、保持力、取り付けやすさなどの要素も考慮することで、プロジェクトに最適なネジを選ぶことができます。

- これらのガイドラインに従い、プロジェクトの具体的な要件を考慮することで、成功した結果を得て、必要に応じた適切なネジを選ぶことができます。

- 最後に、ハードウェアの専門家やメーカーに相談し、最も適した高品質のネジを使用していることを確認し、ファスナー分野の最新の動向や進歩について情報を得ることが重要です。

一般的な用途と産業

ねじは、その多用途性と信頼性からさまざまな産業や用途で使用される重要な締結具です。建設現場では、木ねじやラグボルトがフレーミング、デッキ、キャビネットに頻繁に使用され、木材に対して強力な保持力を発揮します。製造業では、機械ねじが金属やプラスチックの部品を組み立てるために、機械、電子機器などで広く利用されています。 自動車部品金属ねじは、HVACシステム、金属屋根、家電製品など、薄い金属板を固定する必要がある場所で一般的に使用されます。さらに、家具業界では、取り付けやすさと耐久性を考慮した特殊なねじが好まれます。航空宇宙や海洋などの他の産業では、腐食に強く、特殊なコーティングが施されたねじが過酷な環境に耐えるために求められます。全体として、ねじはシンプルな家庭修理から複雑な産業用組み立てまで、数多くのプロジェクトで重要な役割を果たしています。

将来の動向

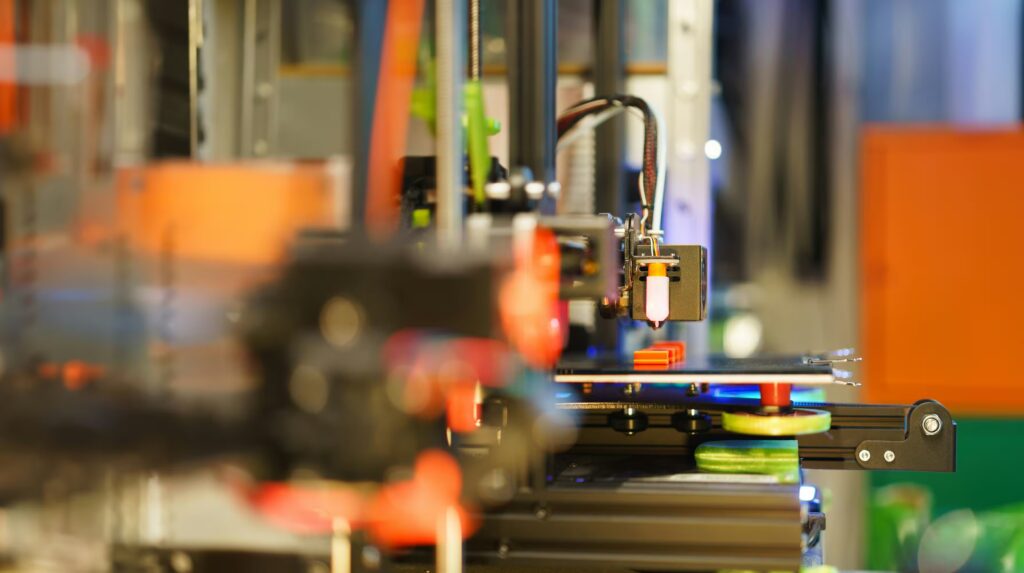

技術と材料科学の進歩に伴い、ねじ業界は新たな要求と課題に対応して進化しています。今後のねじの傾向には、センサーを内蔵し、張力や応力をリアルタイムで監視できるスマートねじの開発が含まれ、安全性やメンテナンス性の向上に寄与します。耐腐食性合金や生分解性ファスナーなどの材料革新も、耐久性と環境持続性を向上させるために注目されています。さらに、進歩した 製造工程精密3Dプリントを含むカスタマイズされたネジ設計は、特定のプロジェクトや用途に合わせて調整可能です。市場では、エルゴノミクスの向上や取り付けやすさを重視したネジの需要も高まっており、電動工具に対応したものや、トルクスやセキュリティヘッドなどの改良されたヘッドデザインを備えた製品が増えています。これらの傾向は、性能向上への継続的な取り組みを反映しています。 締結ソリューションねじは、建設、製造、その他さまざまな産業において不可欠な存在であり続けています。

| カテゴリー | タイプ / 機能 | 説明 | 素材/コーティング | アプリケーション / 産業 | 備考 |

|---|---|---|---|---|---|

| ねじタイプ | 木ねじ | 家庭修理に一般的、耐腐食性、強い保持力 | 鋼、真鍮、ニッケル、青銅、銅 | 住宅修理、家具、木工 | 長さを木の厚さに合わせて選択してください |

| ねじタイプ | 機械用ねじ | 金属およびプラスチックの組み立てに使用され、信頼性の高い固定。 | 鋼、真鍮 ステンレス鋼 | 機械、電子機器、自動車部品 | ナットやタップ穴とともに使用してください。ねじピッチは重要です。 |

| ねじタイプ | 金属用ねじ | 取り付け時にスレッドを形成し、しっかりと固定 | 鋼鉄、亜鉛メッキ | 空調、金属屋根、電化製品 | ねじの長さがシートの厚さに合っていることを確認 |

| ねじタイプ | ラグボルト / ラグスクリュー | 木材および石工用の高耐久ファスナー | 鋼鉄、亜鉛メッキ | 木造構造物、石工 | 割れ防止のために事前に下穴を開ける |

| ねじタイプ | 六角キャップスクリュー | 六角頭スクリュー | 鋼鉄、コーティング済み | エンジニアリング、機械組立 | レンチを使用し、ねじ山の適合性を確認 |

| ねじタイプ | セルフタッピングスクリュー | 自らねじ山を切ることができる | 鋼鉄、ステンレス鋼 | 金属、プラスチック、木材 | 過度な締め付けを避け、材料の割れを防止 |

| ねじ頭 | 平頭 | 表面と平らで滑らかな仕上げ | 鋼鉄、コーティング済み | 家具、内装仕上げ | 美観のための皿頭ねじ込み設置 |

| ねじ頭 | ラウンドヘッド | 丸頭、装飾用 | 鋼、真鍮 | 家具、装飾用途 | 取り付け後も頭部が露出したまま |

| ねじ頭 | プラス / マイナス / トルクス | クロス / シングル / 星形、固定および防 tamper | 鋼鉄、コーティング済み | 家電、電子機器 | 利用可能な工具に基づいて選択 |

| ねじのサイズ | 直径と長さ | 締結強度を決定 | さまざまな材料 | すべての産業 | 適切な直径、長さ、ねじピッチを選択 |

| 用途と産業 | 一般 | 建設、製造、家具、航空宇宙、海洋 | ねじの種類による | 家庭修理、産業用組立、家具製作 | 耐腐食性、保持力、取り付けやすさを考慮 |

| 将来の動向 | スマートネジ&新素材 | 埋め込みセンサー、耐腐食合金、生分解性ファスナー、3Dプリントのカスタムネジ | 先進素材 | 高級機械、航空宇宙、スマートデバイス | 持続可能性と革新的なデザインに焦点を当てる |

世界のトップテンブランド

ネジやファスナーに関しては、品質、革新性、信頼性で世界的に際立つブランドがいくつかあります。これらのトップテンブランドは、さまざまな用途に適した高性能なネジを提供することで、ハードウェアや建設業界で広く認知されています:

- ヒルティ – 高品質と革新性で知られる 締結ソリューション, ヒルティはコンクリート、金属、木材用に設計されたネジを含む幅広い製品を提供しています。

- シンプソン・ストロングタイ – 構造用コネクターとファスナーのリーダーであり、シンプソン・ストロングタイは建設やフレーミングで広く使用される耐久性のあるネジを提供しています。

- GRKファスナー – GRKは自己ドリルおよび自己タッピングネジで有名で、優れた保持力と取り付けやすさを提供します。

- Spax – Spaxのネジは耐腐食性と独特のねじ山設計で知られ、木材や金属の用途に最適です。

- Fastenal – 大手の流通業者兼メーカーであるFastenalは、機械ねじからラグボルトまで、さまざまな種類のネジを供給し、産業および商業のニーズに対応しています。

- Würth – Würthは、腐食防止コーティングや耐久性の高い特殊ネジを含む、幅広いファスナーを提供しています。

- Deckmate – Deckmateは、デッキ用ネジを専門とし、屋外プロジェクトに最適な優れた保持力と耐腐食性を備えた製品を提供します。

- Fischer – Fischerは、高品質のファスナーとアンカーで知られ、石工や重荷重用途向けのネジも含まれます。

- Taptite (ITWブランド) – Taptiteネジは、ねじ山形成能力と強度のために、自動車や製造業界で広く使用されています。

- Kreg – Kregネジは、木工愛好者の間で人気があり、精密さ、使いやすさ、木工プロジェクト向けに特別に設計されたねじ山が特徴です。

これらのブランドは、プロフェッショナルやDIY愛好者の要求を満たすネジを一貫して提供することで、その評判を築いてきました。これらの信頼できるメーカーのネジを選ぶことで、固定作業の成功と耐久性を確保できます。