The Best Uses for Double End Threaded Studs in Construction

ファスニング・ソリューションの紹介

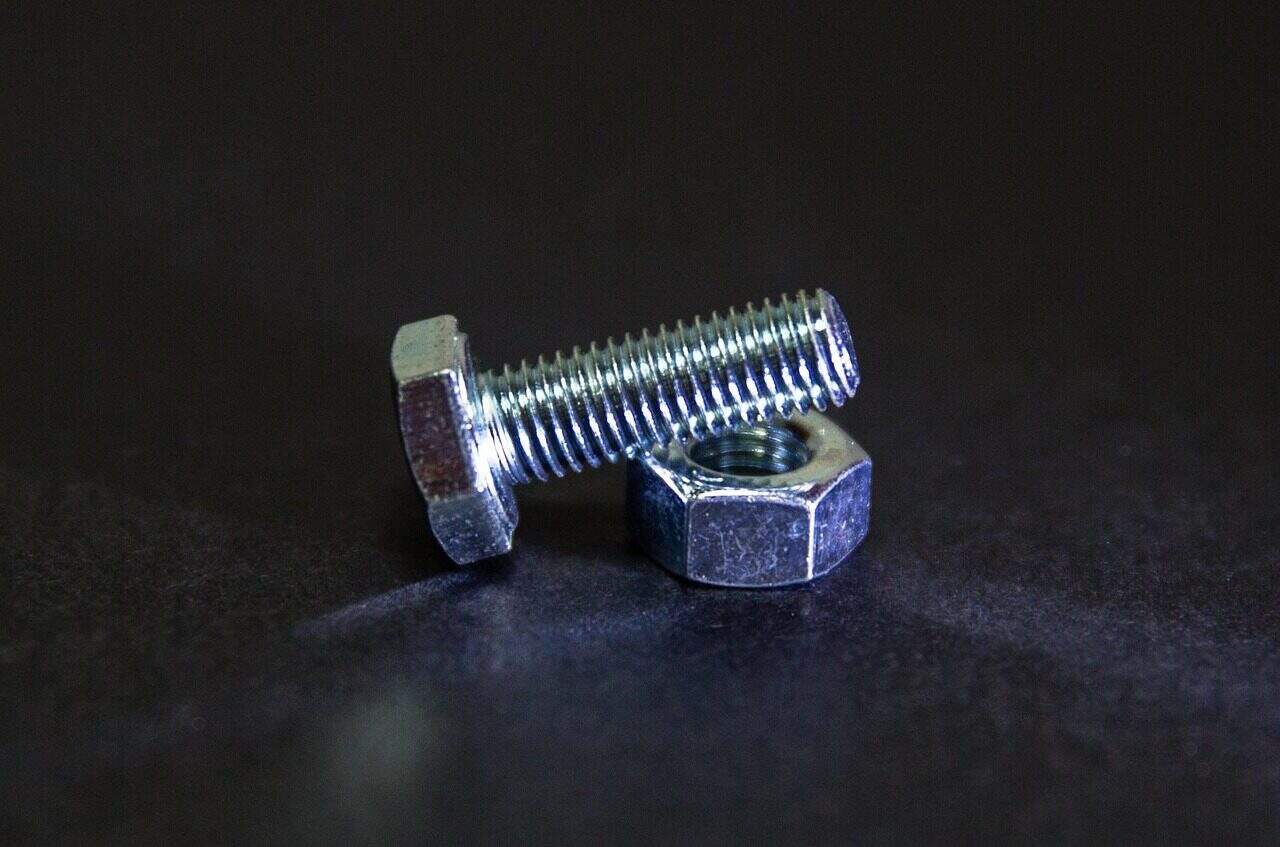

- Double end threaded studs, also known as double end studs or tap end studs, are a type of fastener used in construction to hold two or more parts together.

- These fasteners have threads on both ends with an unthreaded middle section, making them ideal for applications where a strong and secure hold is required.

- Double end studs are available in a variety of sizes, thread counts, and configurations to meet different construction needs.

- They are a popular choice for construction projects due to their durability and strength.

- Double end threaded studs can be used in various construction applications, including building frames, bridges, and other structures.

ファスナーの種類

- Double end studs are a type of fastener that is commonly used in construction, offering a strong and secure hold.

- They are available in different materials, including ステンレス鋼 and carbon steel, to suit various construction needs.

- The thread length of double end studs can vary, with some having a longer thread length than others.

- Double ended studs are also known as tap end studs, and are used to connect two or more parts together.

- They are a type of fastener that is designed to provide a strong and secure hold, making them ideal for construction applications.

Construction Applications

- Double end threaded studs are used in a variety of construction applications, including building frames, bridges, and other structures.

- They are ideal for use in applications where a strong and secure hold is required, such as in heavy construction projects.

- Double end studs can be used to connect two or more parts together, making them a versatile fastener for construction projects.

- They are available in different sizes and thread counts, making them suitable for a range of construction applications.

- Double end threaded studs are a popular choice for construction projects due to their strength and durability.

Benefits of Using Double End Fasteners

- Double end fasteners, such as double end threaded studs, offer a number of benefits for construction projects.

- They provide a strong and secure hold, making them ideal for applications where safety is a concern.

- Double end fasteners are also durable and long-lasting, reducing the risk of failure or damage.

- They are available in a variety of sizes and thread counts, making them suitable for a range of construction applications.

- Double end fasteners are also easy to install, making them a convenient choice for construction projects.

Materials and Grades

- Double end threaded studs are available in a variety of materials, including stainless steel and carbon steel.

- The material used for double end studs will depend on the specific construction application and the level of strength and durability required.

- Double end studs are also available in different grades, including metric and imperial grades.

- The grade of double end stud used will depend on the specific construction application and the level of precision required.

- Double end threaded studs are also available with different finishes, including a corrosion-resistant finish.

Installation and Safety Considerations

- Double end threaded studs should be installed with care to ensure safety and security.

- They should be tightened securely to prevent loosening over time.

- Double end studs should also be inspected regularly to ensure they are in good condition.

- The thread length of double end studs should be checked to ensure it is sufficient for the application.

- Double end threaded studs should be used in accordance with the manufacturer’s instructions to ensure safe and proper use.

Common Applications and Industries

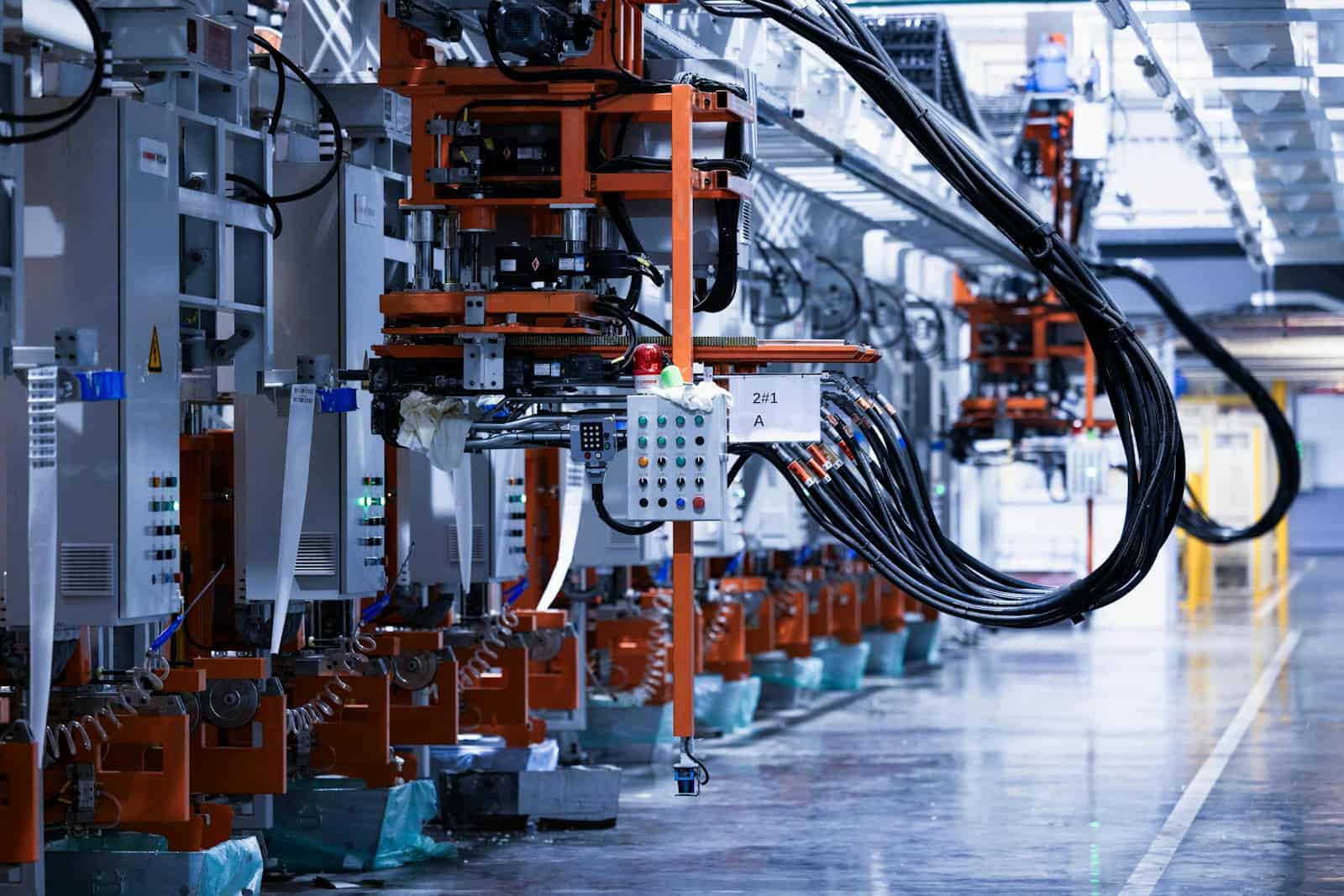

Double end threaded stud screw bolts are widely used across various industries due to their versatility and strength. In construction, they are essential for securely fastening structural components such as steel beams and frames. The automotive industry relies on these fasteners for assembling engines and chassis where a reliable hold is critical. Manufacturing and industrial machinery also utilize double end studs to connect parts that require frequent maintenance or replacement, as the studs allow for easy disassembly.

Other common applications include plumbing, where double end studs help join pipes and fittings, and electrical installations, where they secure panels and enclosures. These fasteners are also prevalent in the aerospace sector, where weight and strength considerations demand high-quality, durable components.

Overall, double end threaded stud screw bolts meet the demands of industries requiring robust, corrosion-resistant, and high-performance 締結ソリューション, making them a preferred choice in a variety of industrial and commercial settings.

Future Trends in Double End Threaded Stud Screw Bolts

As industries continue to evolve, the demand for advanced fastening solutions like double end threaded stud screw bolts is expected to grow. Future trends indicate a focus on enhanced materials and coatings that improve corrosion resistance and durability, especially for use in harsh environments such as marine, aerospace, and chemical industries.

Another trend is the development of custom-sized and precision-engineered double end studs to meet increasingly specific application requirements. This customization allows for better fit, performance, and safety in critical assemblies.

Sustainability is also becoming a priority, with manufacturers exploring eco-friendly production methods and recyclable materials for these fasteners. Additionally, smart fastening technology incorporating sensors to monitor tension and integrity in real-time may emerge, improving maintenance and safety protocols.

Overall, the future of double end threaded stud screw bolts lies in innovation that combines strength, reliability, and adaptability to meet the complex needs of modern industrial applications.

Common Problems & Troubleshooting

While double end threaded stud screw bolts are reliable fasteners, users may encounter some common issues during installation or use. Understanding these problems and how to troubleshoot them can help maintain the integrity and safety of your assembly.

Thread Damage

One frequent problem is thread damage, which can occur if the studs are cross-threaded or overtightened. This can lead to difficulty in installation or removal, and compromise the hold strength. To prevent this, always align the stud carefully before threading and use the correct torque specifications.

腐食

Corrosion is another issue, especially in harsh environments. Over time, rust or other forms of corrosion can weaken the studs, increasing the risk of failure. Using studs with corrosion-resistant finishes or made from stainless steel can mitigate this risk. Regular inspection and maintenance are also recommended.

Loosening

Double end studs may loosen over time due to vibration or thermal expansion. To address this, use appropriate locking mechanisms such as lock nuts, thread lockers, or spring washers. Ensuring proper torque during installation also helps maintain a secure hold.

Incorrect Thread Length

Using studs with an incorrect thread length for the application can lead to insufficient engagement or damage to the parts being fastened. Always verify the required thread length and select studs that meet the specifications for your project.

Installation Errors

Improper installation techniques, such as using the wrong tools or skipping manufacturer instructions, can cause premature failure or unsafe assemblies. Follow all manufacturer guidelines carefully and use tools designed for double end threaded stud screw bolts.

By being aware of these common problems and applying proper troubleshooting techniques, you can ensure that double end threaded stud screw bolts perform effectively and safely in your construction or industrial applications.

参考リンク

- Fastener Standards – ASTM International https://store.astm.org/products-services/standards-and-publications/standards/fastener-standards.html

- ファスナー設計マニュアル - NASAテクニカルレポートサーバー https://ntrs.nasa.gov/api/citations/19900009424/downloads/19900009424.pdf

- ISO 888:2012 – Fasteners — Bolts, screws and studs https://cdn.standards.iteh.ai/samples/50946/fee9720502744f54875f20faf25bcf60/ISO-888-2012.pdf

- Testing of threaded fasteners – ISO 898-1, ISO 3506-1 | ZwickRoell https://www.zwickroell.com/industries/metals/metals-standards/testing-of-threaded-fasteners-to-din-en-iso-898-1/

- Bolt & Stud Thread Engagement | Standard of New England https://www.standardne.com/thread-engagement-an-important-detail/

- 高力ボルトを使用する構造用継手の仕様 - AISC https://www.aisc.org/globalassets/aisc/publications/standards/a348-20w.pdf

- ANSI/AISC 360 Specification for Structural Steel Buildings https://www.aisc.org/publications/steel-standards/aisc-360/

- RCSC Specification | American Institute of Steel Construction https://www.aisc.org/publications/steel-standards/rcsc/

- Fastener – Wikipedia https://en.wikipedia.org/wiki/Fastener

- Bolt (fastener) – Wikipedia https://en.wikipedia.org/wiki/Bolt_(fastener)