The Engineering Principles of Precision Turning: A Deep Technical Analysis

Introduction: Beyond the Lathe

Precision turning might look like a simple process: a spinning workpiece, a cutting tool, and material being removed. However, to achieve accuracy measured in tiny fractions of an inch and mirror-like surface finishes, we must look beyond just the lathe machine. True precision turning isn’t just an operation; it’s a complex, moving system of controlled interactions. It brings together physics, material science, machine movement, and control theory.

This article moves past the basic “what” and digs into the fundamental “why” and “how.” Our goal is to break down the core princípios de engenharia that control the outcome of every cut. We will explore the tiny events at the tool’s edge, the built-in properties of the material being shaped, the advanced engineering of the cutting tool, and the hidden forces that try to reduce accuracy. This is a journey into the science that transforms a raw piece of metal into a component of exact precision. We will treat precision turning as a complete system, understanding that mastery means controlling every variable within that system, from the shear zone of a metal chip to the heat stability of the machine tool.

The Fundamental Physics

To control a process, we must first understand its física básica. At its core, precision turning is a highly controlled breaking and shearing process. What happens in the tiny zone where the tool meets the workpiece determines the final quality of the part. By understanding these first principles, we can make smart, predictable adjustments to our settings.

The Shear Zone Explained

As the cutting tool engages the workpiece, it applies huge compressive stress on the material ahead of it. This material doesn’t simply “get cut”; it deforms plastically until it reaches its maximum shear strength. At this point, the material fails along a plane known as the primary shear zone, which extends from the tool tip to the free surface of the workpiece. This failure is what forms the chip. The nature of this chip tells us a great deal about the process.

- Continuous Chip: This is the ideal for most bendable materials like aluminum or low-carbon steel. A long, continuous ribbon flows smoothly up the tool face. It indicates a stable cutting process and generally results in a good surface finish.

- Discontinuous Chip: Common in brittle materials like ferro fundido or when cutting at very low speeds. The chip forms in small, broken segments. While it offers easy chip management, it can lead to a rougher surface.

- Serrated or Segmented Chip: A semi-continuous chip with a sawtooth-like appearance on the side that was not in contact with the tool. This is typical when machining difficult materials like titanium or nickel alloys at high speeds.

- Built-Up Edge (BUE): This is an unwanted phenomenon where small particles of the workpiece material pressure-weld themselves to the cutting edge. As the BUE grows and then breaks off, it takes fragments of the tool with it and damages the newly machined surface, leading to poor finish and faster tool wear.

The Trinity of Parameters

The interaction within the shear zone is directly controlled by three primary inputs. We call them the trinity of cutting parameters because their balance is critical to success.

- Cutting Speed (Vc): This is the relative velocity between the workpiece surface and the cutting tool, typically measured in surface feet per minute (SFM) or meters per minute (m/min). It is the most significant factor influencing temperature at the cutting zone and has a profound effect on tool life and surface finish.

- Feed Rate (f): This is the distance the tool advances along the axis of the workpiece for every single revolution. It is measured in inches per revolution (IPR) or millimeters per revolution (mm/rev). Feed rate is the primary determinant of the theoretical surface roughness.

- Depth of Cut (ap): This is the thickness of the material being removed from the workpiece radius in a single pass. It directly influences cutting forces, power consumption, and the Material Removal Rate (MRR).

These three parameters are closely linked. Increasing one often requires adjusting another to maintain process stability. For example, a higher feed rate will increase MRR but may worsen surface finish, requiring an adjustment in cutting speed or tool nose radius to compensate.

Analyzing Cutting Forces

Every cutting action generates a reaction force, which can be broken down into three perpendicular components. Understanding these forces provides a diagnostic window into the cutting process.

- Tangential Force (Fc): The largest of the three, acting downward on the tool. It is the primary force determining the power required for the cut.

- Feed Force (Ff): Acts parallel to the workpiece axis, opposing the tool’s feed motion.

- Radial Force (Fr): Acts perpendicular to the workpiece, pushing the tool away from the centerline.

High cutting forces are a direct enemy of precision. The radial force, in particular, can cause the workpiece to bend (especially on long, slender parts) or the tool to push away, resulting in dimensional inaccuracies like taper. For context, turning 6061-T6 aluminum might generate tangential forces in the range of 400-800 N/mm², while turning hardened 4140 steel under similar conditions could easily exceed 2500 N/mm², drastically increasing the risk of deflection. Monitoring these forces is key to diagnosing and preventing errors.

A ciência dos materiais

A cutting tool and a set of parameters that work perfectly for aluminum will fail catastrophically on titanium. The reason lies in the built-in properties of the workpiece material. Precision turning requires us to think like metallurgists, understanding how a material’s internal structure dictates its response to the extreme stresses and temperatures of machining.

Principais propriedades do material

We can predict a material’s behavior by analyzing a few key properties. These characteristics determine everything from chip formation to tool life.

- Hardness & Strength: Hardness is a material’s resistance to localized plastic deformation, such as scratching or indentation. Strength is its ability to withstand an applied load without failure or plastic deformation. Harder, stronger materials require greater cutting forces, generate more heat, and cause more rapid tool wear.

- Ductility: This is a measure of a material’s ability to undergo significant plastic deformation before breaking. Highly ductile materials, like copper or mild steel, tend to form long, continuous chips that can be difficult to manage. Brittle materials, like grey cast iron, have low ductility and form easily managed, discontinuous chips.

- Thermal Conductivity: This property describes how efficiently a material can conduct heat away from the cutting zone. Materials with low thermal conductivity, such as titanium and aço inoxidável, concentrate intense heat at the tool’s cutting edge, leading to rapid thermal wear and potential tool failure. Aluminum, with its high thermal conductivity, dissipates heat effectively, making it much easier to machine.

- Work Hardening: Also known as strain hardening, this is the tendency of a material to become harder and stronger as it is plastically deformed. Materials with a high work hardening rate, like austenitic stainless steels (e.g., 304, 316), become significantly harder in the zone being cut. This means the tool is continuously engaging a surface that is harder than the parent material, leading to accelerated wear and increased cutting forces.

The Machinability Index

To provide a general guideline, engineers developed the machinability index or machinability rating. This is a comparative score that rates a material’s ease of machining against a standard benchmark. The most common benchmark is AISI 1212 steel, which is assigned a rating of 100%. A material with a rating of 50% is considered twice as difficult to machine as 1212 steel, while a material like free-machining brass might have a rating over 300%.

However, we must approach this index with an expert’s caution. It is a useful starting point, but it is not an absolute rule. Real-world machinability is influenced by many other factors that the index doesn’t capture, such as the material’s specific tratamento térmico, variations between batches from the mill, and the rigidity of the machine tool being used. A rating is a guide, not a guarantee.

Table 1: Starting Parameters

The following table provides a practical starting point for several common engineering materials. These values are intended for roughing operations with coated carbide tooling and should be refined based on the specific application, machine rigidity, and desired surface finish.

| Material | Hardness (Brinell) | Recommended Cutting Speed (SFM) | Recommended Feed Rate (IPR) | Key Machining Considerations |

| Aluminum 6061-T6 | 95 HB | 800 – 2000 | 0.008 – 0.020 | Excellent thermal conductivity. Can form a built-up edge (BUE) at lower speeds. Use high speeds and sharp, polished inserts. |

| Baixa Aço carbono 1018 | 126 HB | 600 – 1200 | 0.010 – 0.025 | Very ductile, produces long, stringy chips. Chip control geometry is critical. Good overall machinability. |

| Stainless Steel 304 | 160 HB | 250 – 500 | 0.006 – 0.015 | High work hardening rate. Use a constant feed and avoid dwelling. Low thermal conductivity requires effective cooling. |

| Titanium Ti-6Al-4V | 334 HB | 100 – 200 | 0.005 – 0.012 | Very low thermal conductivity; heat concentrates at the tool edge. High chemical reactivity at temperature. Use low speeds and high-pressure coolant. |

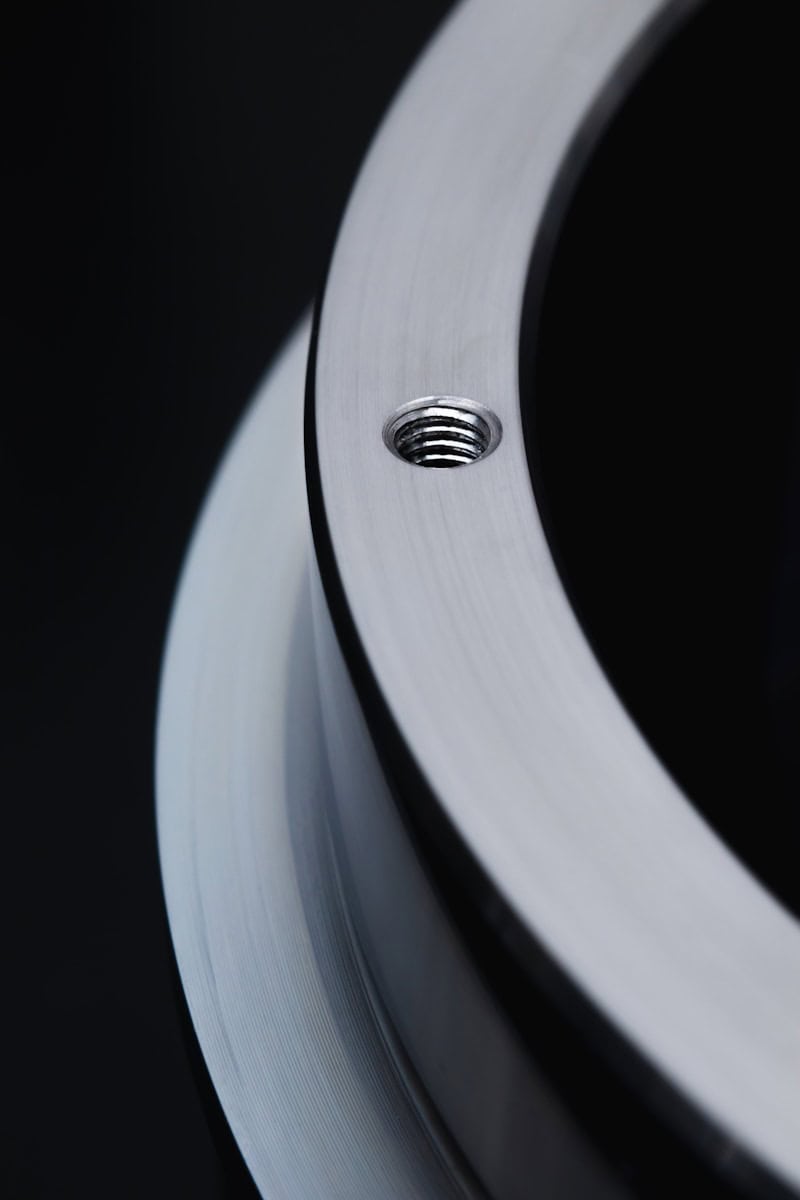

Tooling: The Critical Interface

The cutting tool insert is arguably the most highly engineered component in the entire precision turning system. It is not simply a sharp piece of hard material; it is a sophisticated instrument where geometry, substrate, and coatings are precisely designed to manage forces, control chip flow, and resist wear at extreme temperatures and pressures.

Dissecting Tool Geometry

The shape of the cutting edge is defined by a series of critical angles and features. Each one has a specific function and represents a carefully considered engineering trade-off.

- Rake Angle: This is the angle of the tool’s top face (the rake face) relative to a plane perpendicular to the workpiece surface. It controls chip formation and cutting forces.

- Positive Rake: The rake face slopes away from the cutting edge. It reduces cutting forces, generates less heat, and is ideal for soft, ductile materials like aluminum.

- Negative Rake: The rake face slopes toward the cutting edge. This creates a much stronger edge, suitable for heavy cuts, hard materials, and interrupted cuts. However, it increases cutting forces and temperature.

- Neutral Rake: A zero-degree angle, used in specific applications like machining brass or for form tools.

- Clearance (Relief) Angle: This is the angle between the tool’s flank (side) and the newly machined workpiece surface. Its purpose is to prevent the tool from rubbing against the part, which would cause friction, heat, and a poor surface finish. It must be large enough to provide clearance but not so large that it weakens the cutting edge.

- Nose Radius: This is the radius of the tool’s tip. It is a critical factor in determining surface finish and tool strength. There is a fundamental trade-off: a larger nose radius can produce a superior surface finish at a given feed rate and provides a stronger cutting edge. However, it also increases radial cutting forces, which can lead to chatter and deflection. A smaller nose radius reduces cutting forces but leaves more pronounced “cusps” on the surface, resulting in a rougher finish.

Hierarchy of Tool Materials

The evolution of cutting tool materials is a story of a relentless pursuit of hardness, toughness, and thermal stability.

- High-Speed Steel (HSS): The original high-performance tool material. It offers excellent toughness, making it resistant to chipping, but has a relatively low hot hardness, limiting cutting speeds.

- Cemented Carbide: The workhorse of modern machining. Made by sintering tungsten carbide (WC) particles in a cobalt (Co) binder. It offers a great balance of hardness and toughness. Modern carbide tools are almost always coated.

- Coatings (TiN, TiAlN, etc.): Micro-thin layers of ceramic materials are applied via PVD or CVD processes. These coatings act as a thermal barrier, increase surface hardness, and provide lubricity, dramatically improving tool life and performance.

- Ceramics & Cermets: Exceptionally high hot hardness and chemical stability, allowing for very high cutting speeds in materials like cast iron and hardened steels. However, they are brittle and have low thermal shock resistance.

- Cubic Boron Nitride (CBN) & Polycrystalline Diamond (PCD): These are superabrasive materials. CBN is second only to diamond in hardness and is used for turning hardened ferrous metals. PCD is the hardest known material and is used for machining non-ferrous and abrasive non-metallic materials like high-silicon aluminum, composites, and ceramics.

Table 2: Advanced Materials

For the most demanding applications, engineers turn to advanced tool materials. This table compares the top-tier options.

| Atributo | Cemented Carbide (Coated) | Cubic Boron Nitride (CBN) | Polycrystalline Diamond (PCD) |

| Composition | Tungsten Carbide (WC) particles in a Cobalt (Co) binder, with ceramic coatings (e.g., TiAlN). | Synthetic CBN crystals sintered onto a carbide substrate. | Synthetic diamond particles sintered together, often on a carbide substrate. |

| Hardness (Knoop) | ~1800 – 2400 | ~4500 – 5000 | ~6500 – 8000 |

| Aplicativo | General purpose machining of steels, stainless steels, cast irons, and non-ferrous alloys. | Hard turning of ferrous materials (>45 HRC), such as hardened steels and chilled cast irons. | High-speed finishing of non-ferrous and non-metallic materials (aluminum, brass, composites, carbon fiber). |

| Prós | Excellent balance of hardness and toughness. Versatile and cost-effective. Wide variety of geometries and grades. | Extreme hot hardness. Chemically stable with ferrous materials. Allows for replacement of grinding operations. | The ultimate in hardness and wear resistance. Can achieve exceptional surface finishes. Excellent thermal conductivity. |

| Contras | Lower hot hardness compared to ceramics/CBN. Limited speeds in very hard materials. | Brittle and sensitive to interrupted cuts. High cost. Not suitable for soft materials. | Very brittle. High cost. Chemically reactive with ferrous materials at high temperatures, making it unsuitable for steel. |

Enemies of Precision

In a perfect world, a rigid machine with a perfect tool would produce a perfect part. In reality, we operate in a world filled with “unseen enemies”—subtle forces and phenomena that constantly work to degrade accuracy. Identifying and reducing these error sources is the hallmark of a true precision expert.

Battle Against Heat

Heat is the primary enemy in precision turning. The energy from plastic deformation and friction shows up as intense heat, concentrated in a tiny area. This heat causes thermal expansion in the workpiece, the tool, and even the machine tool structure itself. A part measured at 200°C will be a different size when it cools to an ambient temperature of 20°C. This thermal growth is a direct source of dimensional error.

Mitigation is centered on thermal management and stability.

- Coolant/Lubricant Strategy: The most direct approach is the application of cutting fluid.

- Flood Cooling: The traditional method of showering the cutting zone with a low-pressure, high-volume flow of coolant. It is effective at bulk heat removal and chip flushing.

- High-Pressure Coolant (HPC): Delivers a focused, high-velocity jet of coolant directly at the cutting edge. This can break the vapor barrier that forms at high temperatures, providing more effective cooling and also aiding in chip control by breaking chips into manageable sizes.

- Minimum Quantity Lubrication (MQL): Also known as near-dry machining, this method delivers a fine aerosol of oil in an air stream. It focuses on lubrication rather than cooling, reducing friction and thus the amount of heat generated in the first place.

- Machine Warm-up Cycles: Running a machine’s spindle and axes before starting critical work helps bring the entire structure to a stable operating temperature, minimizing thermal drift during the machining process.

Taming Instability and Chatter

Chatter, or self-excited vibration, is a destructive phenomenon that can ruin a part in seconds. It occurs when the cutting force causes the tool or workpiece to deflect, which then changes the chip thickness. This change in chip thickness alters the cutting force, creating a feedback loop that results in violent vibration. The result is a terrible surface finish with characteristic wave patterns and, often, catastrophic tool failure.

Common causes include:

- Lack of system rigidity (machine, tool holder, workpiece).

- Excessive tool overhang.

- Incorrect cutting parameters that excite a natural frequency of the system.

- Dull or incorrect tool geometry.

Mitigation involves increasing system stiffness (shorter tools, better workholding) and adjusting cutting parameters. Advanced engineering utilizes tools like stability lobe diagrams, which are plots of axial depth of cut versus spindle speed. These diagrams map out the speed-parameter combinations that are dynamically stable (chatter-free) and those that are unstable, allowing engineers to scientifically select chatter-free cutting conditions.

The Foundation of Accuracy

Ultimately, the precision potential of any turning operation is limited by the machine tool itself. No amount of process optimization can overcome the inherent kinematic errors of the machine. These are the foundational errors built into the machine’s structure and motion systems.

- Machine Base Rigidity: A massive, well-damped machine base (often made of polymer concrete or cast iron) absorbs vibrations and provides a stable platform.

- Guideway Straightness and Spindle Runout: The ways that guide the machine’s axes must be perfectly straight and parallel. The spindle must rotate with minimal radial or axial deviation (runout). Any error in these components will be directly copied onto the workpiece.

- Control System and Servo Performance: The CNC control’s ability to precisely command and verify the position of the cutting tool, and the servo motors’ ability to execute those commands without overshoot or lag, are critical for contouring accuracy and positional repeatability.

Table 3: Diagnostic Guide

The ability to diagnose a problem from the evidence left on a part is a critical skill. This table serves as a quick-reference troubleshooting guide for common precision turning errors.

| Symptom / Error | Likely Technical Cause(s) | Mitigation Strategies |

| Tapered diameter on a long part | 1. Workpiece deflection under radial cutting forces. 2. Thermal growth of the headstock moving it away from the tailstock. | 1. Use a tailstock or a steady rest for support. 2. Reduce depth of cut and/or feed rate to lower forces. 3. Run machine warm-up cycles to achieve thermal stability. |

| Poor surface finish with visible marks | 1. Chatter/vibration. 2. Incorrect feed rate for the tool nose radius. 3. Built-up edge (BUE) formation. | 1. Shorten tool overhang. Increase system rigidity. Adjust cutting speed (often higher or lower can move out of an unstable zone). 2. Use the formula for theoretical finish to match feed to nose radius. 3. Increase cutting speed or use a coated/sharper tool. |

| Inconsistent part dimensions batch-to-batch | 1. Machine thermal instability (parts made when cold are different from parts made when warm). 2. Progressive tool wear. | 1. Implement a consistent machine warm-up protocol. Control shop floor temperature. 2. Use tool wear compensation in the CNC program. Monitor tool life and replace inserts at predictable intervals. |

| Short tool life | 1. Cutting speed is too high for the material. 2. Low thermal conductivity of workpiece material is “cooking” the tool. 3. Incorrect tool grade or geometry. | 1. Reduce cutting speed. 2. Improve coolant application (e.g., switch to high-pressure coolant). 3. Select a tougher grade of carbide or a more heat-resistant coating (e.g., TiAlN). |

Conclusion: A Holistic System

We began this analysis by stating that precision turning is a system. Throughout our exploration, this theme has been reinforced at every level. We have seen that the quality of a turned component is not the result of a single, perfectly executed action, but the sum of dozens of controlled variables. It is a chain of dependencies that begins with the physics of shearing a metal chip.

This chain extends to the metallurgical properties of the workpiece, which dictate the forces and temperatures that the system must endure. It includes the sophisticated geometry and material science of the cutting tool, the critical interface where theory meets reality. It is governed by the dynamic stability of the entire machine and tool assembly, where unseen enemies like heat and vibration constantly threaten to break the chain. Finally, it is all managed by a control system executing a strategy based on a deep understanding of these interconnected principles.

Achieving the highest levels of precision is not about memorizing speeds and feeds. It is about understanding the “why” behind them. It is about viewing the entire process, from matéria-prima to finished dimension, as one holistic and dynamic system. By adopting this principles-based approach, engineers, designers, and machinists are empowered not just to follow instructions, but to innovate, troubleshoot complex challenges, and continue to push the boundaries of what is possible in manufacturing.

- Machining and Metalworking – SME https://www.sme.org/technologies/machining-metal-cutting/

- CNC Machining Basics – Engineering ToolBox https://www.engineeringtoolbox.com/

- Precision Machining Technology – Machine Design https://www.machinedesign.com/

- Metal Cutting and Tool Wear – ASME https://www.asme.org/

- Manufacturing Processes – Wikipedia https://en.wikipedia.org/wiki/Machining

- CNC Turning Services – Thomasnet https://www.thomasnet.com/products/cnc-turning-services-73131200-1.html

- Lathe Operations and Turning – IQS Directory https://www.iqsdirectory.com/articles/machine-shop/lathe.html

- Cutting Tools and Machining Parameters – Journal of Manufacturing Science and Engineering https://www.asme.org/topics-resources/content/manufacturing-science-engineering

- Mechanical Engineering Resources – U.S. Bureau of Labor Statistics https://www.bls.gov/ooh/architecture-and-engineering/mechanical-engineers.htm

- Precision Manufacturing Technology – MIT OpenCourseWare https://ocw.mit.edu/courses/mechanical-engineering/