A Complete Guide to Cell Tower Setup: Building Better Mobile Networks

Why Getting It Right Matters

Setting up cell towers correctly is absolutely essential for creating a strong, reliable mobile network. This is where radio wave science, building engineering, and computer networking all come together in one physical location. Just one loose connection, a poorly calculated weight load, or an antenna pointing the wrong way can hurt the performance of a network worth millions of dollars and affect thousands of phone users. This guide goes beyond basic instruction manuals to give engineers and project managers the detailed technical knowledge they need for network setup. It breaks down the main principles that make an installation successful.

We will carefully look at the technical parts needed for successful base station installation, covering:

- O basic parts of a modern cell tower.

- The science and engineering rules for choosing locations.

- A comparison of different setup methods.

- A step-by-step breakdown of the physical installation process.

- Special considerations for 5G network setups.

- The final testing and approval phase.

Isso guide is designed as a technical resource, giving you the deep understanding needed to complete base station installation with the accuracy required for the best network performance.

What’s Inside a Modern Cell Tower

A modern cell tower isn’t one big piece of equipment but a system of specialized parts working together. Understanding what each part does is important for knowing how they depend on each other during installation. The system is split between ground-level processing and high-up radio transmission.

Baseband Unit (BBU)

The Baseband Unit (BBU) is the computer brain of the cell site. Usually kept in a climate-controlled building or cabinet at the bottom of the tower or in a building’s equipment room, the BBU handles all digital signal processing. It manages call transfers between towers, schedules network resources, and communicates with the main network. It turns voice and data into digital signals for transmission and processes signals received from user phones. The BBU connects to the radio units through high-speed fiber optic cables.

Remote Radio Unit (RRU/RRH)

The Remote Radio Unit (RRU), also called a Remote Radio Head (RRH), is the “muscle” of the system. Its main job is to convert the digital signal from the BBU into an analog Radio Frequency (RF) signal, boost it to the needed power level, and send it to the antenna. It also receives weak RF signals from the antenna, amplifies them, and converts them to digital for transport to the BBU. Placing the RRU close to the antenna reduces cable length, which greatly reduces signal loss and improves overall system efficiency, especially for receiving weak signals from phones.

Antenna System

The antenna system converts electrical signals into radio waves and vice versa. It is the network’s “mouth and ears.” Panel antennas are most common in modern cellular networks, designed to create directional coverage “sectors” (typically three 120-degree sectors per site). Key concepts include polarization (using multiple orientations to improve signal strength), azimuth (horizontal pointing), and mechanical/electrical tilt (vertical pointing). Advanced antennas support beamforming, which dynamically focuses radio energy toward specific users.

Power and Cooling Systems

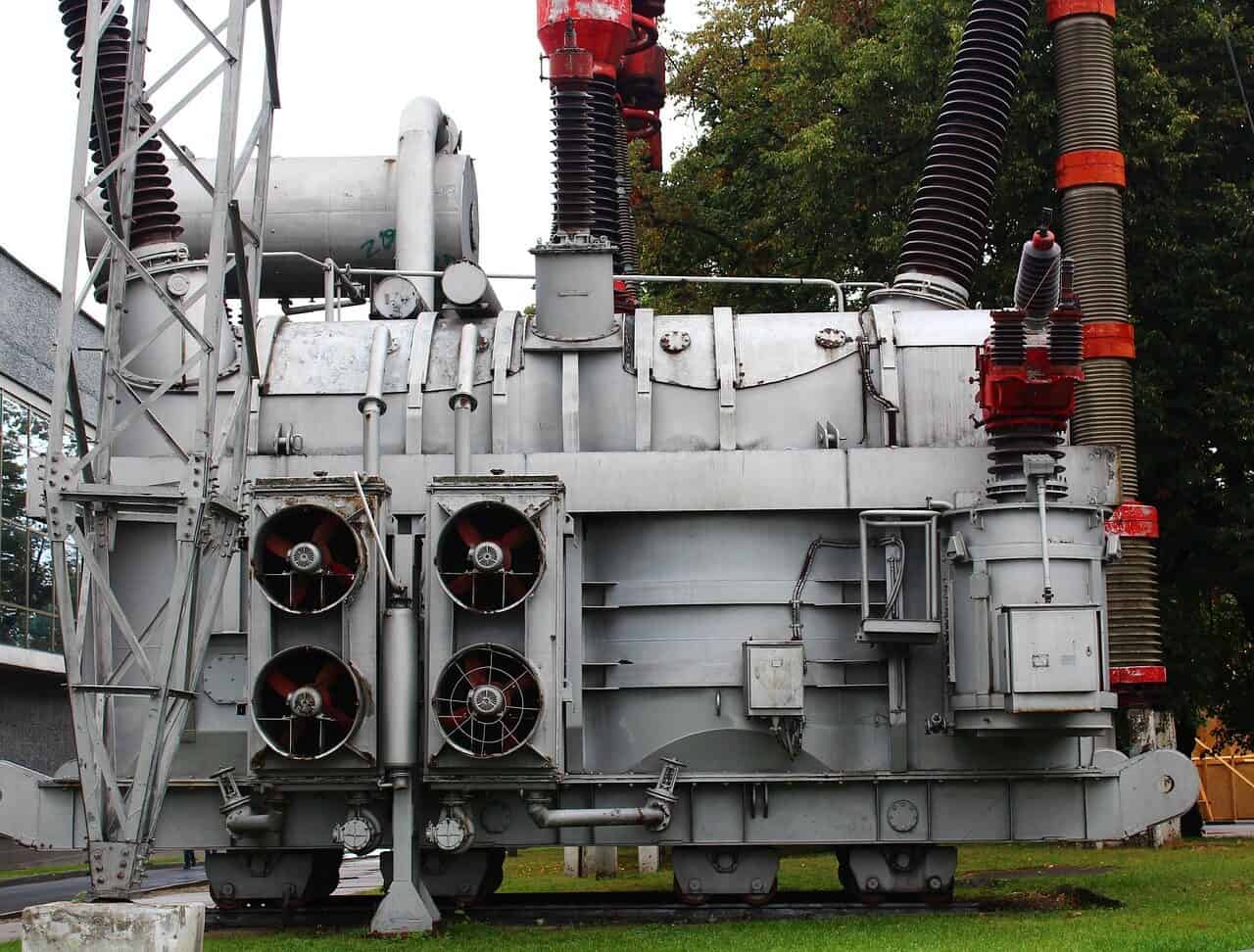

The power system is the lifeline. Cell towers need highly reliable, clean power. An AC power feed is typically converted to -48V DC, the standard for telecom equipment. A rectifier system does this conversion and charges a bank of batteries. This Uninterruptible Power Supply (UPS) ensures the site keeps working during power outages for a specified time. Cooling, through HVAC units or high-efficiency fans, is equally important, as the BBU and RRUs create significant heat that must be removed to prevent equipment failure.

Backhaul Interface

The backhaul provides the site’s connection to the wider world—the carrier’s main network and the internet. High-capacity fiber optic cable is preferred because of its huge bandwidth, low delay, and reliability. Where fiber isn’t available or costs too much, high-frequency microwave links are used, requiring precise line-of-sight alignment between two dish antennas. The choice of backhaul technology is a fundamental design decision that determines the site’s maximum data speed capacity.

| Table 1: Comparison of Base Station Classifications |

| Tipo |

| Macrocell |

| Microcell |

| Picocell |

| Femtocell |

The Science of Choosing Locations

Choosing where to put a cell tower is the most important planning step of base station installation. It’s an engineering discipline based on the physics of how radio waves travel. The best location maximizes coverage and capacity while minimizing interference and cost. A poor choice can never be fully fixed by equipment, no matter how advanced.

Radio Wave Analysis

Radio waves don’t travel in a simple, straight line. Radio wave analysis uses mathematical models to predict how a signal will behave in a given environment. Models like Okumura-Hata or COST 231 are used for large cell planning, accounting for urban density and terrain type. Key phenomena that must be modeled include:

- Path Loss: The natural reduction in signal strength as it travels through space.

- Shadowing: Signal weakening caused by large obstacles like hills or buildings.

- Multipath Fading: Destructive and constructive interference as a signal arrives at the receiver through multiple paths (reflections, bending around obstacles).

Frequency is a major factor. Lower frequency bands (like 700 MHz) travel farther and penetrate buildings more effectively than mid-bands (like 2.5 GHz). High-frequency millimeter wave bands (like 28 GHz) have extremely limited range and are easily blocked by obstacles.

Link Budget Calculation

A link budget is a formal accounting of all gains and losses a radio signal experiences as it travels from the transmitter to the receiver. Its purpose is to ensure the received signal is strong enough to maintain a quality connection. The simplified formula is:

`Received Power = Transmitted Power + Gains – Losses`

Each term represents an important engineering value:

- Transmitted Power: The output power of the RRU.

- Gains: Primarily antenna gain, which focuses radio energy in a specific direction.

- Losses: A combination of Free Space Path Loss (FSPL), cable and connector losses, penetration losses (walls, trees), and a fading margin to account for signal changes.

A positive link margin (received power exceeding receiver sensitivity) is required for a strong connection.

Interference and PIM Avoidance

In a dense network, a cell site must deal with interference from its neighbors. Co-channel interference (from sites using the same frequency) and adjacent-channel interference (from sites on neighboring frequencies) must be managed through careful frequency planning and antenna placement.

A more hidden problem is Passive Intermodulation (PIM). PIM is a form of self-interference created when two or more strong radio signals encounter non-linearities in passive components like connectors, cables, or even nearby rusty metal (fences, roofs). These non-linear junctions act like mixers, creating new, unwanted signals that can fall directly into the sensitive uplink band, raising the noise floor and severely hurting call and data performance. Site selection should actively avoid potential PIM sources.

Structural and Environmental Factors

The chosen site must be able to physically support the equipment. A structural analysis is required to calculate the total load, including the weight of antennas, RRUs, mounts, and cabling. Importantly, this analysis must also account for wind load, which puts significant force on the tower or building structure, especially on large antenna arrays. Environmental factors also play a key role. The site must be assessed for lightning risk, requiring a strong grounding and surge protection plan. Year-round access for maintenance vehicles, including cranes if necessary, is a logistical requirement that cannot be overlooked.

Installation Methods Analysis

Choosing the right installation method involves a series of technical and financial trade-offs. The best choice depends on the network goal, whether it’s broad coverage, targeted capacity, or indoor penetration. We analyze the three primary methods across key engineering criteria.

New Tower Installation

A new installation involves building a new tower (monopole, self-support, or guyed) on an undeveloped piece of land.

- Radio Performance: Unmatched. This method provides the greatest flexibility in height and location, allowing engineers to place the antenna at the ideal point for maximum coverage and minimal obstruction. It is the standard for rural and suburban large cell deployments.

- Structural Challenge: Significant. This is a major civil engineering project. It requires soil surveys to assess ground stability, a large concrete foundation, and a multi-stage tower construction process. Deployment timelines are the longest, often spanning several months.

- Power & Backhaul: Complex and costly. Utility power and fiber backhaul often need to be extended to the site, which can involve extensive digging, boring, or the installation of new utility poles, adding substantial cost and coordination overhead.

Rooftop Installation

This common urban and suburban method involves mounting antennas and equipment on the roof of an existing building.

- Radio Performance: Very good, but with limitations. Rooftops provide excellent height. However, performance can be hurt by obstructions from adjacent, taller buildings or by clutter from existing rooftop equipment like HVAC units, which can cause signal reflections and blocking. The metal structures on many commercial roofs are also a high-risk source of PIM.

- Structural Challenge: Critical. A licensed structural engineer must perform a detailed analysis to confirm the building’s roof can support the combined weight and wind load of the proposed installation. All roof holes for cable runs and mounting hardware must be carefully sealed and weatherproofed to prevent leaks and maintain the building’s integrity.

- Power & Backhaul: Generally more accessible. Connecting to the building’s existing power and communications infrastructure is typically easier than a new build. However, this may still require dedicated, high-amperage power lines and complex in-building fiber runs from the rooftop to the building’s telecom connection point.

Small Cell / Street Furniture

Small cells are low-power nodes installed on streetlights, utility poles, or the sides of buildings to add targeted capacity and fill coverage gaps.

- Radio Performance: Highly localized. The low mounting height and power level mean coverage is limited, often to a block or less. Performance is highly affected by blockage from street-level obstacles like buses, trees, and even dense pedestrian traffic. This method is for adding capacity, not wide-area coverage.

- Structural Challenge: Deceptively complex. While the equipment is smaller and lighter, the analysis is no less thorough. The existing utility pole or structure must be analyzed for its ability to handle the added wind load. Appearance and compliance with local zoning laws and public right-of-way regulations are major project hurdles.

- Power & Backhaul: Often the biggest challenge. Finding a viable power source can involve complex negotiations to tap into a streetlight’s power circuit. Securing a fiber backhaul connection to a utility pole in the middle of a city block is a significant logistical and financial undertaking, sometimes costing more than the radio equipment itself.

The Installation Process Breakdown

The physical installation is a sequence of precise actions where following engineering specifications is extremely important. A mistake at any step can compromise the integrity of the entire system. This process is a craft guided by technical drawings and best practices.

1. Site Preparation and Safety

Before any equipment is unpacked, the site must be prepared. This begins with establishing a safe work zone, using cones, tape, and signs to control access, particularly if lifting operations are planned. All delivered components must be carefully checked against the Bill of Materials (BOM) and inspected for shipping damage. A final, on-site risk assessment is conducted to identify any new or previously unforeseen hazards.

2. Structural and Mount Assembly

This stage involves the assembly of the antenna mounting hardware, whether it be tower standoffs or rooftop sleds, according to the structural engineering drawings. This is a safety-critical step. All hardware must be tightened to the manufacturer’s exact specifications to prevent loosening from wind-induced vibration over time. An important but often overlooked detail is preparing all grounding and bonding points. This involves removing paint or rust to create a bare metal-to-metal connection and applying an anti-rust compound before final assembly to ensure a low-resistance, long-lasting electrical bond.

3. Antenna and RRU Lifting

Lifting heavy and expensive antennas and RRUs to height requires certified rigging equipment and trained personnel. A gin pole or crane is used, and a tag line must always be used to control the load’s swing and prevent collisions. Once lifted, the equipment is mounted. The antenna’s azimuth must be set precisely using a calibrated compass, referencing the radio design plan. The mechanical tilt is set using a digital angle meter. After mounting the RRUs, the short radio jumper cables connecting them to the antenna ports must be attached. Every outdoor radio connection must be weatherproofed using a multi-layer wrap of butyl rubber mastic and vinyl electrical tape to prevent moisture entry, a leading cause of PIM and system failure.

4. Cable Routing and Management

Proper cable management is not just for looks; it is essential for long-term reliability. A clear separation must be maintained between different cable types: radio jumpers, fiber optic (CPRI/eCPRI) lines, DC power cables, and grounding wires. Each cable type has a specified minimum bend radius that must be respected; kinking a fiber optic or radio cable will permanently hurt its performance. Cables should be secured to the tower or cable tray using UV-resistant ties or clamps at regular intervals. A “drip loop” must be formed on all external cables just before they enter the shelter or cabinet. This simple U-shaped bend ensures that rainwater drips off the bottom of the loop rather than tracking along the cable into the equipment enclosure.

| Table 2: Technical Site Survey Checklist |

| Categoria |

| Radio Assessment |

| Structural |

| Power & Grounding |

| Backhaul |

| Logistics |

5G Era Advanced Considerations

The deployment of 5G networks, particularly those using Massive MIMO and millimeter wave (mmWave) frequencies, introduces a new level of technical complexity to base station installation. These technologies demand a major shift in installation precision and technique.

Massive MIMO Antenna Arrays

Massive MIMO antennas, which can contain 64 or more individual transceiver elements, are the engine behind 5G’s capacity gains. However, their physical characteristics present significant installation challenges.

- Weight and Wind Load: These arrays are much larger and heavier than their 4G predecessors. This requires stronger mounting hardware and, in many cases, retrofitting or strengthening of existing towers and rooftop structures to handle the increased static weight and dynamic wind loading.

- Precise Calibration: The effectiveness of 5G beamforming is entirely dependent on the precise physical orientation of the antenna. While azimuth and tilt remain important, the antenna’s roll (or plumb) is now equally critical. Even a one-degree error in roll can cause the narrow beams to form incorrectly, significantly hurting performance and efficiency. Installation requires high-precision, three-axis measurement tools.

Millimeter Wave Radio Installation

mmWave deployments, using high-frequency bands like 3GPP’s n257 (28 GHz), n260 (39 GHz), and n261 (24 GHz), are essential for achieving multi-gigabit speeds. Their propagation physics require a completely different installation strategy.

- Extreme Sensitivity to Blockage: mmWave signals behave more like light than traditional radio waves. They are severely weakened by common materials like glass, leaves, and even the human body. This “blockage” effect means that clear line-of-sight is not just preferred; it is often required. Installers must carefully plan placements to avoid even minor obstructions.

- Reduced Range: The high path loss at these frequencies limits the effective range of a mmWave radio to 200 meters or less in a typical urban canyon. This requires a very dense network topology, with installations on lampposts, traffic signals, and building facades, moving the base station from the rooftop to the street level.

Power and Cooling for 5G

The advanced processing and high number of transceivers in 5G active antennas (where radio and antenna are integrated) lead to a big increase in power consumption and heat generation compared to 4G passive antenna systems. A site’s DC power plant and battery backup often need to be upgraded to handle the higher load. Similarly, the heat output requires more effective cooling solutions, particularly for compact small cell enclosures where heat removal is a primary design constraint.

Post-Installation and Testing

The installation process is not complete until the site is powered on, configured, and thoroughly tested to verify it meets all performance specifications. This commissioning and integration phase is the final quality check before the site is allowed to carry live customer traffic.

System Commissioning and Integration

This phase begins with powering up the equipment in a controlled sequence. The BBU is connected to the backhaul circuit and establishes a link with the core network. The fiber optic links (CPRI or eCPRI) between the BBU and the RRUs are then activated. Technicians load the site-specific software and configuration files, which define the cell’s operating parameters, such as frequencies, power levels, and neighbor lists.

Critical Performance Testing

Once the system is configured, a series of tests is performed to validate the quality of the physical installation.

- VSWR/Return Loss Sweeps: A Vector Network Analyzer (VNA) is used to send a signal up the radio path and measure the amount of signal reflected back. High VSWR (Voltage Standing Wave Ratio) or low Return Loss indicates a problem, such as a bad connector, a kinked cable, or a faulty antenna.

- PIM Testing: A specialized PIM tester injects two high-power tones into the radio path and measures for any intermodulation products. If PIM levels are unacceptable, the team must troubleshoot the line, checking tightness on connectors and searching for external PIM sources.

- Fiber Optic Testing: An Optical Time-Domain Reflectometer (OTDR) is used to test the integrity of the fiber runs between the BBU and RRUs, identifying any excessive bends, bad splices, or dirty connectors.

- Call and Throughput Testing: The final validation involves using test devices to make voice calls and run data speed tests (like FTP downloads, streaming video) in each sector of the cell. This confirms that the site is performing as expected from a user’s perspective.

| Table 3: Key Commissioning Test Parameters & Acceptance Criteria |

| Test Parameter |

| VSWR (Voltage Standing Wave Ratio) |

| Return Loss |

| PIM (Passive Intermodulation) |

| RSSI (Received Signal Strength Indicator) |

| RSRP (Reference Signal Received Power) |

Reunindo tudo isso

A successful base station installation is far more than a construction task; it is the physical combination of multiple engineering disciplines. It demands a deep understanding of radio frequency physics, the precision of structural and electrical engineering, and the accuracy of information technology. From careful, model-based site selection to the final, data-driven acceptance tests, every step must be executed according to exact technical principles. As networks evolve with AI-driven optimization and a focus on energy-efficient “green” base stations, this multi-disciplinary, technically precise approach will only become more critical for building the communications infrastructure of the future.

- Fastener Installation Standards – ASTM International https://www.astm.org/

- Bolt Installation and Torque – ISO https://www.iso.org/

- Structural Bolting – RCSC (Research Council on Structural Connections) https://www.boltcouncil.org/

- Bolted Joint Design – ASME https://www.asme.org/

- Bolt Tightening Methods – Wikipedia https://en.wikipedia.org/wiki/Bolted_joint

- Fastener Technology – SAE International https://www.sae.org/

- Instituto de Fixadores Industriais https://www.industrial-fasteners.org/

- Structural Steel Construction – AISC https://www.aisc.org/

- Bolt Installation Engineering – ScienceDirect https://www.sciencedirect.com/topics/engineering/bolt-tightening

- Fabricação e fixação - Thomasnet https://www.thomasnet.com/