Understanding Laser Direct Structuring: A Guide to Advanced Techniques

Introduction to LDS

- Laser Direct Structuring (LDS) is a manufacturing process that implements conductive traces directly on an injection moulded component, integrating complex mechanical designs.

- LDS technology enables full 3D structures by using thermoplastic material as the substrate, allowing integration of complex mechanical designs in miniature 3D shapes.

- The LDS process consists of three main phases: injection molding of the thermoplastic material to form the component, laser activation to define circuit patterns, and metallization to create conductive traces. This may be followed by SMT or soldering for component assembly.

- Key benefits of LDS include improved wireless performance, reduced assembly costs, and the ability to place antennas outside devices.

- LDS is suitable for producing components with unique antenna patterns, reducing the need for additional tooling costs.

The LDS Process

- The LDS process starts with injection molding, which creates 3D components using LDS-capable thermoplastics blended with metal-organic compounds.

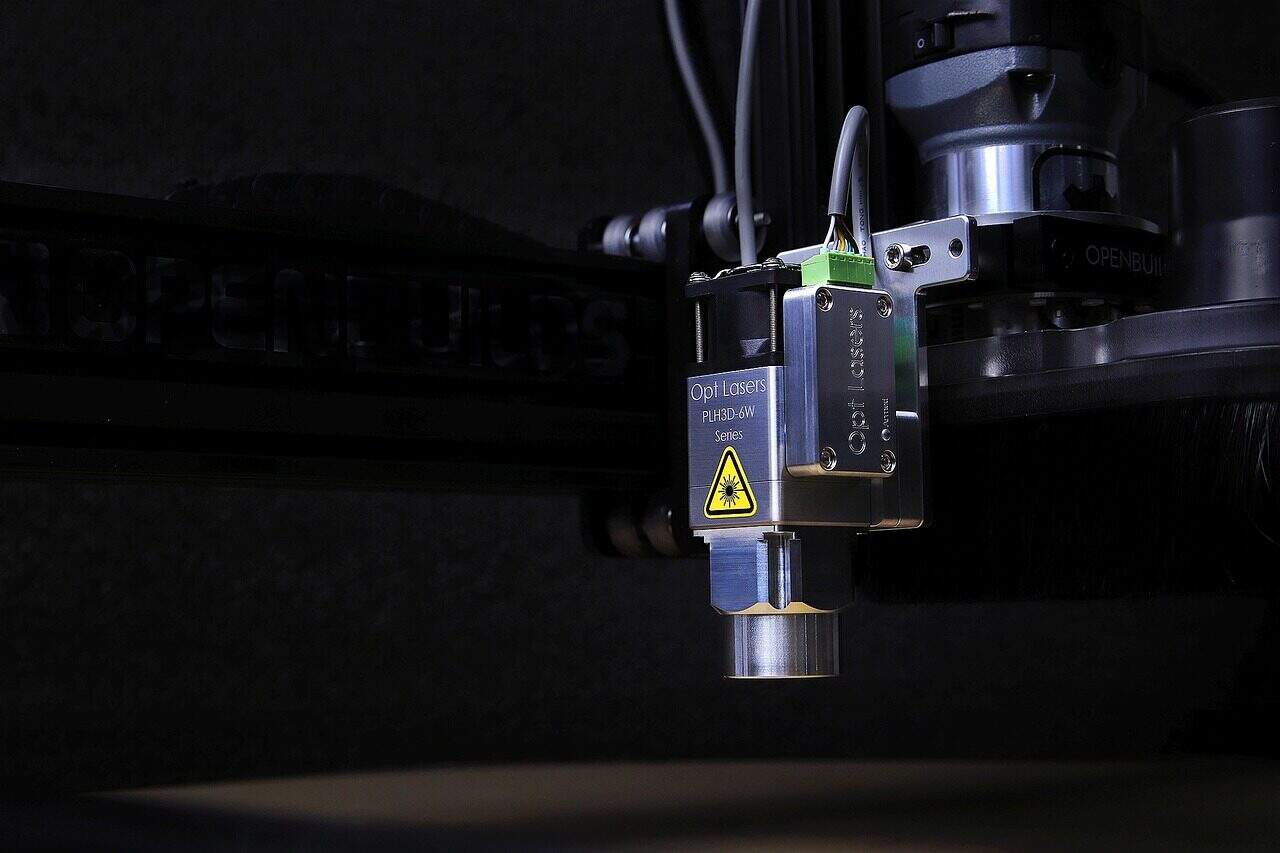

- During laser activation, the laser activates copper ions within the material to form circuit traces. Lasering activation is a crucial step where the laser activates the conductive areas on the plastic substrate, enabling the subsequent metallization step.

- In the plating process, the component is immersed in a plating bath that deposits copper, nickel, or other metals onto the lasered area, creating a conductive trace.

- Additional steps include the SMT process for component assembly, surface finishing, and final product inspection to ensure high-quality integration of electronics on 3D injection molded parts.

- The LDS process allows for the creation of molded interconnect devices (MIDs) with complex mechanical designs.

LDS Technology

- LDS technology is a key manufacturing process for producing 3D-MIDs with conductive traces, enabling the integration of electronic components and circuit traces into 3D plastic parts.

- Laser direct structuring (LDS) allows for more curves and smaller form factors than traditional technologies like stamped metal or flexible printed circuits.

- LPKF laser is a notable provider of LDS technology, offering solutions for producing 3D molded interconnect devices with integrated conductive traces.

- The technology compared to traditional manufacturing methods offers several advantages, including reduced assembly costs and improved wireless performance.

- LDS is particularly useful for medical devices, where maintaining small form factors and reducing assembly costs are crucial.

- The process enables the creation of components with desired shapes and unique antenna patterns.

Key Benefits

One of the key benefits of LDS is the reduction of assembly costs, as antennas can be implemented directly on the device, saving space and reducing the need for additional components.

LDS technology also enables design flexibility, allowing for the creation of complex designs and unique antenna patterns. It allows manufacturers to integrate complex mechanical designs directly into injection-molded components, providing greater flexibility and enhanced performance.

The process supports surface mount technology (SMT) and is suitable for mass production, making it an attractive option for manufacturers.

Additional benefits include the ability to produce several antennas on a single injection molded part, reducing production costs and improving efficiency.

LDS is also beneficial for medical technology, where the ability to create complex designs and reduce assembly costs is crucial.

Injection Molding

- Injection molding is the first step in the LDS process, creating 3D components using LDS-capable thermoplastics blended with metal-organic compounds.

- The process involves injecting molten plastic into a mold, which is then cooled and ejected, creating a 3D component with the desired shape.

- The molded part is then ready for laser activation, which triggers a chemical reaction, forming fine metal particles on treated surfaces.

- Injection molding is a critical step in the LDS process, as it determines the shape and quality of the final product.

- The process requires specialized tools and equipment, including traditional molding tools and laser processing machines.

Laser Direct

Laser Direct Structuring (LDS) is transforming the way manufacturers approach the integration of electronic components and antennas into injection molded plastic parts. This advanced manufacturing process leverages the precision of laser technology to create conductive traces and complex mechanical designs directly on the surface of injection molded components. By combining injection molding with laser activation and subsequent metallization, LDS enables the seamless incorporation of electronic functionality into three-dimensional plastic parts.

The LDS process begins with the creation of the desired shape using injection molding, producing a robust and lightweight plastic component. Next, a laser direct structuring LDS step selectively activates specific areas of the plastic, preparing them for the formation of conductive traces. This laser activation is crucial, as it defines the exact paths for electrical connectivity and allows for the integration of antennas and other electronic features without the need for additional assembly steps.

One of the key benefits of this technology is the significant reduction in assembly costs. By implementing antennas and conductive traces directly onto the injection molded plastic, manufacturers can eliminate the need for separate circuit boards or additional wiring. This not only streamlines the manufacturing process but also enhances wireless performance by allowing antennas to be optimally positioned within the device. The result is a more compact, reliable, and efficient product that meets the demands of modern electronic applications.

LDS technology is particularly valuable for industries requiring complex mechanical designs and high-performance wireless components, such as medical devices, automotive systems, and consumer electronics. The ability to integrate multiple functions into a single component, while maintaining small form factors and reducing assembly costs, makes laser direct structuring a preferred choice for innovative product development.

Direct Structuring

Direct Structuring is at the heart of the LDS process, enabling manufacturers to create intricate patterns and conductive traces on injection molded plastic parts with unmatched precision. Using a laser processing machine, specific areas of the plastic material are activated, allowing for the subsequent deposition of metals that form the essential conductive pathways for electronic components and antennas.

This approach offers several advantages over traditional manufacturing methods. By utilizing direct structuring, manufacturers can achieve complex designs and unique antenna patterns that would be challenging or cost-prohibitive with conventional techniques such as stamped metal or flexible printed circuits. The flexibility of the LDS process means that even the most complex mechanical designs can be realized without the need for additional tooling, significantly reducing both production time and costs.

A key benefit of direct structuring is the ability to reduce assembly costs by integrating conductive traces and antennas directly onto the molded part. This eliminates the need for extra components and simplifies the overall assembly process, making it easier to maintain small form factors and achieve space savings within the final product. The technology also supports the production of components with desired shapes and geometries, which is particularly important for applications in medical devices, automotive electronics, and wireless communication systems.

Furthermore, the LDS process is environmentally friendly, as it minimizes material waste and reduces the reliance on traditional molding tools and additional assembly steps. By leveraging the capabilities of laser direct structuring, manufacturers can produce high-quality, reliable components that meet the demands of modern electronic devices while also supporting sustainable manufacturing practices.

In summary, direct structuring through the LDS process empowers manufacturers to design antennas and other electronic features directly onto injection molded plastic parts, offering unmatched design flexibility, cost savings, and enhanced wireless performance. This innovative manufacturing technology is paving the way for the next generation of compact, efficient, and highly functional electronic products.

Materials and Metallization

- The LDS process requires specialized materials, including LDS-capable thermoplastics blended with metal-organic compounds.

- The metallization process deposits copper, nickel, or other metals onto the lasered area, creating a conductive trace.

- The choice of material and metallization process is critical, as it determines the quality and performance of the final product.

- The process involves several steps, including surface preparation, plating, and inspection.

- The materials and metallization process used in LDS are critical to the creation of high-quality components with unique antenna patterns.

Design Considerations

- Design considerations are critical in the LDS process, as they determine the quality and performance of the final product.

- The design process involves creating a pattern design that takes into account the capabilities and limitations of the LDS process.

- The process requires specialized software and expertise, including knowledge of laser processing and metallization.

- Design considerations include the choice of material, the design of the antenna pattern, and the creation of a suitable shape for the component.

- The design process is critical to the creation of high-quality components with unique antenna patterns.

Applications and Examples

- LDS technology has a wide range of applications, including medical devices, automotive, and consumer electronics.

- The process is particularly useful for producing components with unique antenna patterns, such as antennas for wireless devices.

- Examples of LDS applications include molded interconnect devices (MIDs), 3D-MIDs, and laser-structured antennas.

- The process is also suitable for producing components with complex designs, such as medical devices and automotive parts.

- LDS technology is used in various industries, including medical technology, automotive, and consumer electronics.

Future Developments

- Future developments in LDS technology are expected to focus on improving the efficiency and accuracy of the process.

- Advances in laser processing and metallization are expected to enable the creation of more complex designs and unique antenna patterns.

- The development of new materials and technologies, such as nanotechnology and 3D printing, is expected to further enhance the capabilities of LDS.

- The process is expected to become more widespread, with increased adoption in various industries, including medical technology, automotive, and consumer electronics.

- Future developments will focus on improving the performance, efficiency, and cost-effectiveness of LDS technology.

Conclusion

- In conclusion, LDS technology is a powerful tool for producing components with unique antenna patterns and complex designs.

- The process offers several advantages, including reduced assembly costs, improved wireless performance, and the ability to create complex designs.

- The LDS process consists of injection molding, laser activation, and metallization, and requires specialized equipment and expertise.

- The technology has a wide range of applications, including medical devices, automotive, and consumer electronics.

- LDS is expected to continue to evolve, with advances in laser processing, metallization, and materials science enabling the creation of more complex designs and unique antenna patterns.

Economic and Environmental Implications

- The economic implications of LDS technology are significant, as it enables the reduction of assembly costs and the creation of complex designs.

- The process also has environmental implications, as it reduces the need for additional materials and minimizes waste.

- The use of LDS technology can also reduce the carbon footprint of manufacturing, as it enables the creation of more efficient and compact components.

- The process is also expected to have a positive impact on the economy, as it enables the creation of new jobs and industries.

- The economic and environmental implications of LDS technology make it an attractive option for manufacturers and consumers alike.

Reference Links:

- Molded interconnect device – Wikipedia https://en.wikipedia.org/wiki/Molded_interconnect_device

- 3D-MID Technology with Laser Direct Structuring (LDS) – LPKF https://www.lpkf.com/en/industries-technologies/electronics-manufacturing/3d-mids-with-laser-direct-structuring-lds

- What Are Molded Interconnect Devices or MIDs? – Altium https://resources.altium.com/p/what-are-molded-interconnect-devices-or-mids

- What are molded interconnect devices? – EDN https://www.edn.com/what-are-molded-interconnect-devices/

- Process chains for the manufacturing of molded interconnect devices – ResearchGate https://www.researchgate.net/publication/225625164_Process_chains_for_the_manufacturing_of_molded_interconnect_devices

- A fast and flexible method for manufacturing 3D molded interconnect devices – ScienceDirect https://www.sciencedirect.com/science/article/pii/S1875389210005109

- Injection moulding – Wikipedia https://en.wikipedia.org/wiki/Injection_moulding

- Injection Moulding Process – ScienceDirect Topics https://www.sciencedirect.com/topics/engineering/injection-moulding-process

- Advanced Injection Molding Methods: Review – PMC (NIH) https://pmc.ncbi.nlm.nih.gov/articles/PMC10489002/

- Injection Molding of Thermoplastics – SpringerLink https://link.springer.com/chapter/10.1007/978-1-4615-7604-4_5