You’ve probably grabbed whichever fastener was sitting in the toolbox without thinking twice. Most people do. But if you’re building a deck, assembling machinery, or specifying parts for a structural project, picking the wrong one isn’t just inconvenient — it can genuinely compromise the safety and integrity of the whole job. The bolt vs screw question is older than most people realize, and it’s still one that trips up experienced builders and DIYers alike.

The short answer: a bolt is designed to be used with a nut, tightened from the nut end; a screw is designed to be driven into a material directly, tightened by torquing the head. But the real difference goes much deeper than that — thread design, shear strength, load distribution, material compatibility, and application context all play into when each fastener actually belongs.[fastenermart]

This guide breaks it all down cleanly and honestly, including the cases where the line between a bolt and a screw gets genuinely blurry.

Bolt vs Screw: The Definitions That Actually Matter

Let’s start with the official standard. According to ANSI/ASME B18.2.1, cited by the U.S. Customs and Border Protection for classification purposes:[wilsongarner]

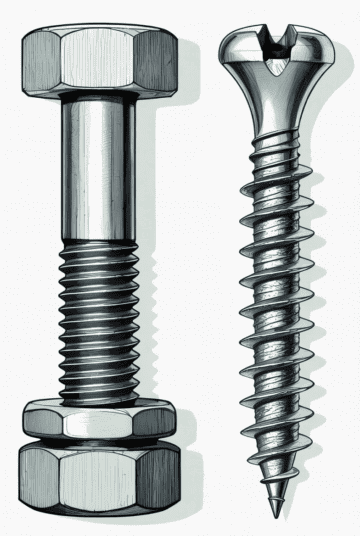

Bolt: An externally threaded fastener designed for insertion through holes in assembled parts, and normally intended to be tightened or released by torquing a nut.

Screw: An externally threaded fastener capable of being inserted into holes in assembled parts, of mating with a preformed internal thread or forming its own thread, and tightened or released by torquing the head.

That single distinction — where the torque is applied — is the cleanest functional separator. A bolt relies on a mating nut to clamp parts together. A screw engages the material itself, either threading into a pre-tapped hole or cutting its own path.[fastenermart]

Here’s where it gets interesting: in everyday conversation, people call hex-head cap screws “bolts” all the time. And technically, many of them are being used as bolts when paired with a nut — even though they’re manufactured as screws. The hardware industry doesn’t always make this easy.

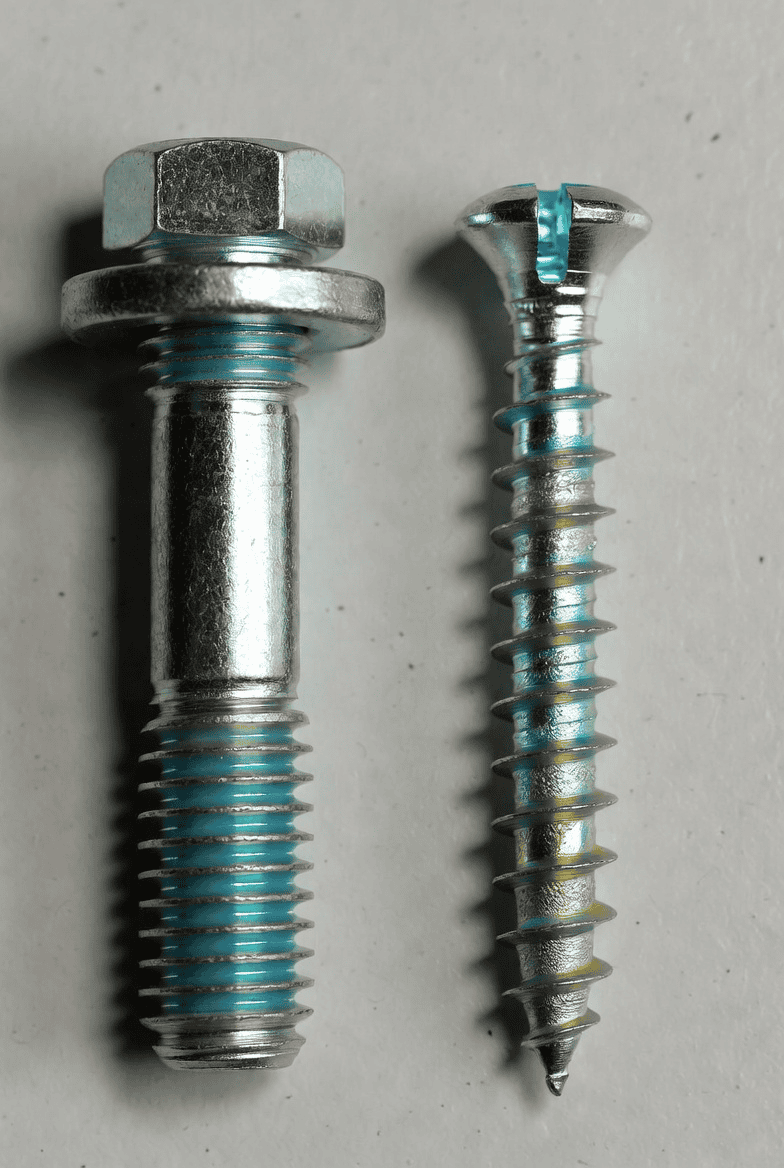

Physical Differences: What to Look For

Knowing the definition is useful. Being able to tell them apart by sight in the field is more useful. Here’s how the two types actually differ at the physical level:

| Feature | Bolt | Screw |

|---|---|---|

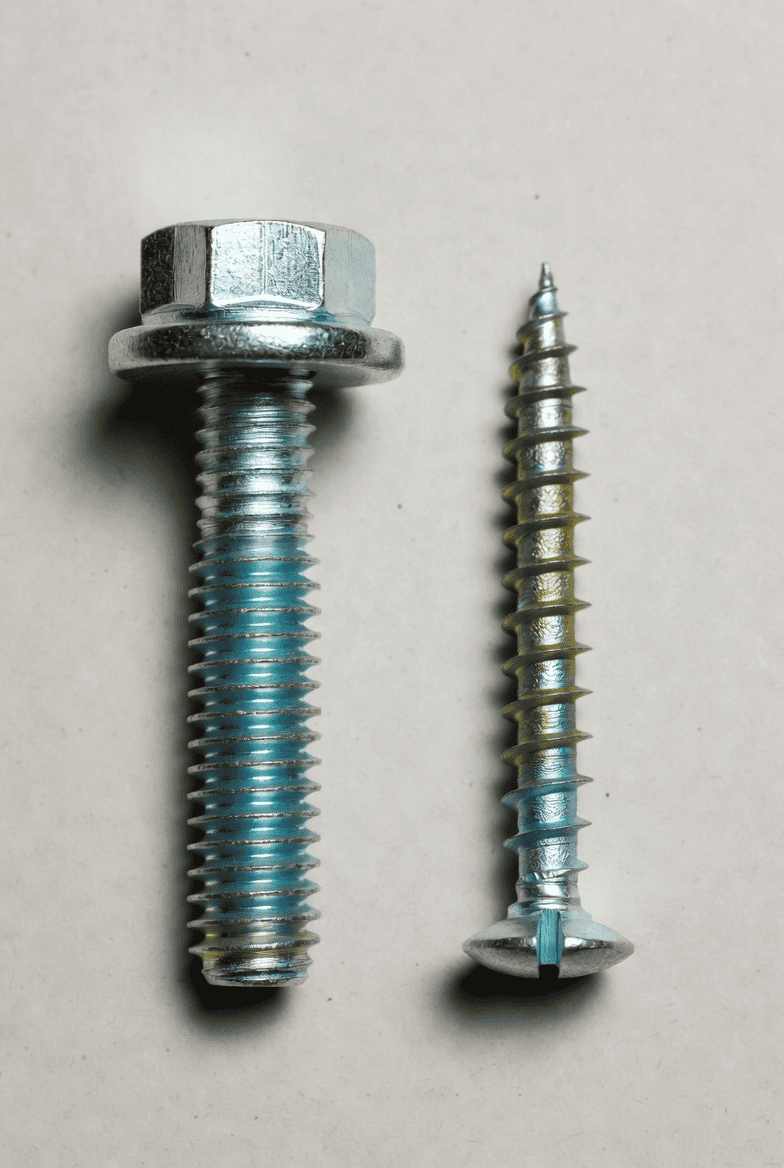

| Threading | Usually partially threaded (smooth shank portion) | Almost always fully threaded to the head [fastenright] |

| Head style | Hex head most common; no drive recess typically | Wide variety: Phillips, flat, hex socket, Torx, etc. [allpointsfasteners] |

| Nut required? | Yes, normally | No — engages material or tapped hole directly |

| Shank | Smooth (unthreaded) section present on most | Thread runs the full length |

| Installation | Inserted through a clearance hole, nut tightened from opposite side | Driven directly into wood, metal, plastic, or pre-tapped hole |

| Point style | Blunt or flat end | Often has a tapered or sharp point to aid entry |

The smooth shank on a bolt is not accidental. That unthreaded section sits across the shear plane — the point where two parts meet — and provides significantly greater resistance to sideways (shear) forces than a fully threaded fastener can. When you’re joining structural steel or securing heavy machinery, that shear strength differential is the reason engineers specify bolts over screws every single time.[fastenright]

Types of Bolts and Screws: More Variety Than You Think

Both categories contain a wide enough range of subtypes that entire catalogs are dedicated to them. Here’s a working overview:

Common Bolt Types

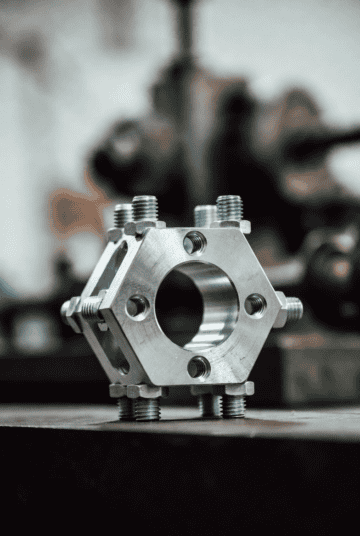

Hex bolt — The workhorse of structural construction. Wide, flat hexagonal head; partially threaded; used with a nut and washer. Standard in steel framing, bridge construction, and heavy equipment.[componentsolutionsgroup]

Carriage bolt — Smooth domed head with a square neck under it. The square neck bites into wood to prevent rotation as you tighten the nut. Common in wood-to-wood and wood-to-metal connections.[componentsolutionsgroup]

Structural bolt (ASTM A325/A490) — Heat-treated high-tensile bolts for load-bearing structural steel joints, regulated by building codes. Not interchangeable with standard hex bolts in rated connections.[componentsolutionsgroup]

Eye bolt — Has a loop at one end; used for lifting, rigging, and attaching cables.

U-bolt — U-shaped; used to secure pipe, tubing, or round surfaces.[boltdepot]

J-bolt — J-shaped; used in anchor applications, particularly in concrete foundations.

Shoulder bolt — Also called a stripper bolt; has a precision smooth shoulder that acts as a pivot point in assemblies.[boltdepot]

Common Screw Types

Wood screw — Tapered body with sharp point; partially threaded; designed to bite into wood without a pre-drilled hole in most applications.

Machine screw — Fully threaded with a uniform body; requires a tapped hole or a nut. Used extensively in electronics, appliances, and light machinery.[donghefastener]

Sheet metal screw — Fully threaded with a sharp point; self-tapping into thin metal sheet without pre-tapping.

Self-drilling screw (Tek screw) — Has a drill-bit tip that bores its own hole before threading. Eliminates pre-drilling step entirely.

Concrete screw — Case-hardened screw that threads directly into concrete after pilot hole drilling (e.g., Tapcon).

Lag screw — Also sometimes called a lag bolt; has a hex head and is driven into wood or masonry with a wrench. Technically a screw despite the common name.

Decking screw — Coated for corrosion resistance; optimized for outdoor hardwood and composite decking applications.

Bolt vs Screw: Side-by-Side Performance Comparison

When the situation calls for a decision — which one do you actually reach for? These are the technical factors that should drive that choice:

| Factor | Bolt Wins When… | Screw Wins When… |

|---|---|---|

| Load bearing (tension) | Heavy structural loads; high clamping force needed via nut [essentracomponents] | Light to medium loads; clamping force less critical |

| Shear strength | High shear forces at joint (smooth shank resists lateral stress) [fastenright] | Shear loads are minimal |

| Adjustability | Need to disassemble/reassemble repeatedly without damaging material | Permanent or semi-permanent fixing preferred |

| Installation access | Both sides of the joint are accessible | Only one side is accessible |

| Material depth | Thicker materials that can’t be tapped economically [donghefastener] | Thin materials, wood, pre-tapped components |

| Speed of installation | Less critical; two-sided installation takes longer | Important; screws install from one side only |

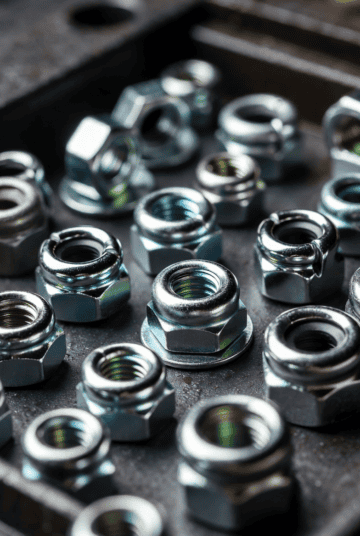

| Vibration resistance | Can loosen without locking mechanism; requires lock washers or Nyloc nut | Thread engagement in material often resists vibration better |

One point worth dwelling on: the bolt vs screw choice isn’t always about strength in absolute terms. A properly sized wood screw into seasoned hardwood can hold more in direct pull-out than a bolt through thin plywood. Context — material type, load direction, access, and expected service conditions — should drive the decision every time.[essentracomponents]

Materials and Coatings: What the Fastener Is Made Of Matters

The bolt vs screw debate doesn’t end at the thread. Both come in a wide range of materials, and using the wrong one accelerates corrosion, causes galvanic reactions, or simply snaps under load.

Common fastener materials:

Grade 5 / Grade 8 carbon steel bolts — The standard for general structural use in North America. Grade 8 (metric 10.9) has higher tensile strength; used in automotive and heavy machinery.

Stainless steel (304 / 316) — Excellent corrosion resistance. 316 specifically handles marine environments and chemical exposure where 304 would fail.[essentracomponents]

Zinc-plated (electroplated) steel — Basic corrosion protection for indoor or sheltered applications. Thin coating wears quickly outdoors.

Hot-dip galvanized — Thick zinc coating for outdoor, ground-contact, or concrete-embedded applications. The only acceptable spec for pressure-treated lumber connections in most building codes.

Hardened alloy steel — Used for critical load-bearing connections in construction and industrial machinery.

Galvanic corrosion is a real hazard that gets overlooked. When you pair aluminum framing with steel fasteners in a wet environment — without an isolating barrier — the aluminum will corrode at an accelerated rate. Stainless steel is the correct pairing for aluminum assemblies exposed to moisture.[essentracomponents]

Industry Applications: Where Each Fastener Actually Works

Construction and Structural Steel

The bolt is the dominant fastener in structural steel construction for one simple reason: it can be tension-controlled during installation. High-strength structural bolts (ASTM A325 and A490) are tightened to a precise preload, creating a clamped joint that distributes load across the contact surfaces rather than relying solely on the fastener itself. Screws simply can’t replicate this in steel-to-steel connections at structural scale.[componentsolutionsgroup]

That said, screws dominate in wood framing, sheathing, drywall, and decking — applications where one-sided installation is essential and shear loads are managed by the wall or floor system as a whole.

Automotive and Machinery

Modern vehicle assembly uses both extensively, and the distinction becomes nuanced fast. Cylinder head bolts (technically often called bolts or studs depending on configuration) are torqued to precise specifications because under-torquing causes head gasket failure, over-torquing strips threads or distorts the head. Machine screws handle interior trim, electronics mounting, and smaller assemblies.[donghefastener]

Heavy machinery — excavators, industrial presses, conveyor systems — relies on high-grade hex bolts for all load-bearing connections. The maintenance cycle often involves re-torquing or replacing bolts on a schedule, something machine screws in the same role couldn’t handle repeatedly.[essentracomponents]

Electronics and Consumer Appliances

Machine screws are everywhere in electronics enclosures, circuit board standoffs, panel fastening, and heat sink attachments. The precision of a machine screw into a tapped hole allows consistent torque values in sensitive assemblies. Bolts rarely appear in this space — clearance holes and two-sided installation don’t suit the compact, dense layouts of consumer electronics.

Marine and Outdoor Environments

316 stainless steel fasteners — both bolts and screws — are standard in marine hardware because of their superior chloride resistance. Silicon bronze screws are also commonly used in wooden boat construction for their combination of corrosion resistance and aesthetic finish. The bolt vs screw decision in marine contexts also factors heavily in accessibility: underwater or hull-adjacent connections often favor through-bolts (bolts with backing plates) precisely because they can be serviced from inside the vessel.[essentracomponents]

Common Mistakes That Will Cost You Time (and Sometimes Safety)

These are mistakes that show up repeatedly — and most of them are avoidable once you know what to look for:

Using a bolt where a screw was specified (and vice versa):

This sounds obvious, but it happens. Someone substitutes a lag screw for a through-bolt in a deck ledger connection because it’s faster. The lag screw provides less clamping force and — critically — doesn’t create the through-connection that building codes require for that joint.[componentsolutionsgroup]

Ignoring thread pitch:

Metric and imperial fasteners look identical at a glance but will not thread into each other’s holes. Cross-threading damages both the fastener and the host material. Always verify thread pitch before installation.

Over-torquing screws in soft materials:

Wood screws driven flush are fine. Driven past flush — past “snug” into the countersink — they start to lose holding strength immediately. The thread is designed to grip at a specific depth; crushing the surface fiber eliminates that grip.

Mixing stainless hardware with carbon steel in marine environments:

Stainless steel and carbon steel in contact with seawater creates a galvanic cell. The carbon steel corrodes rapidly, sometimes catastrophically. In marine applications, keep materials consistent.[essentracomponents]

Stripping heads through mismatched drivers:

A Phillips driver that’s even slightly too small for the screw head will cam out under torque and round out the recess. Use the right driver size — it actually matters more than most people realize, especially with stainless screws where the head is harder to drill out if it strips.

Future Trends: Where Fastener Technology Is Heading

The bolt vs screw distinction isn’t going anywhere, but the fasteners themselves are evolving.

Smart fasteners and torque monitoring: Industrial bolting increasingly incorporates embedded sensors that monitor preload in real time. This is particularly active in wind turbine construction and bridge maintenance, where periodic re-torquing of hundreds of structural bolts is a safety-critical maintenance operation. Sensor-equipped bolts transmit load data continuously, eliminating manual inspection cycles.

Non-metallic fasteners expanding into structural roles: CFRP (carbon fiber reinforced polymer) bolts and screws are already used in aerospace and high-performance automotive applications where weight is a design constraint and metallic fasteners add unacceptable mass. Expect these to migrate into architectural glazing and lightweight modular construction over the next decade.

Self-healing thread compounds: Research into micro-encapsulated adhesives integrated into thread coatings is showing promise. The concept: the coating releases a bonding agent only under the shear stress of loosening, effectively self-locking the fastener in response to vibration without requiring application of thread locker during assembly.

Additive manufacturing (3D printing) of fasteners: Custom-geometry bolts and screws are already being 3D-printed in titanium and high-strength alloys for aerospace and medical device applications. Lead times that once took weeks for specialty fasteners are compressed to days. As metal printing costs drop, this will move into industrial maintenance and specialty construction.

Sustainability-driven material shifts: Fastener manufacturers are responding to procurement requirements from major construction contractors that specify lower embodied carbon. This is driving interest in recycled-content steel bolts, bio-based composite screws for non-structural applications, and coating systems that eliminate hexavalent chromium (still widely used in older zinc-chromate coatings).[essentracomponents]

FAQ

Is a lag bolt a bolt or a screw?

Despite the name, a lag bolt is technically a screw. It has a hex head and is driven directly into wood or masonry without a nut — which, by the ANSI definition, makes it a screw. The “bolt” name is purely colloquial and has stuck because of its large size and hex head appearance.[wilsongarner]

Can a bolt be used without a nut?

A bolt driven into a pre-tapped hole technically functions as a screw in that application. Many cap screws (hex socket head screws) are regularly used this way. However, a standard through-bolt with no nut provides no clamping force and should not be substituted into a bolted joint specification.[fastenermart]

Which is stronger in pull-out: a bolt or a screw?

In wood, a fully threaded wood screw typically outperforms a smooth-shanked bolt for direct pull-out resistance because the full thread profile engages more wood fiber. In metal-to-metal connections, a properly torqued bolt develops far greater clamping force and tensile load capacity. The answer is always material- and application-specific.[fastenright]

What does “grade” or “class” mean on fastener markings?

Grade (US) and Class (metric) indicate the tensile and yield strength of the fastener. Grade 2 is low-strength common hardware. Grade 5 is medium-strength (SAE), marking three radial lines on the head. Grade 8 is high-strength, marking six radial lines. Metric Class 8.8 and 10.9 are roughly equivalent to Grades 5 and 8, respectively. Never substitute a lower grade for a higher-grade fastener in a structural or safety application.[componentsolutionsgroup]

Why do some screws look exactly like bolts?

Hex-head cap screws are the most common source of confusion. They look like bolts, they’re often called bolts in casual use, and they function as bolts when paired with a nut. But when driven into a tapped hole without a nut, they function as screws. The same physical fastener can operate as either depending on installation method — which is why the official definitions focus on how they’re used, not just what they look like.wilsongarner+1

Authoritative External References

The following sources were referenced in preparing this guide and are recommended for further reading:

Bolts and screws – what is the difference? — Fastenright

https://www.fastenright.com/blog/bolts-and-screws-what-is-the-difference[fastenright]Bolts vs. screws: What’s the difference and when to use each — Essentra Components

https://www.essentracomponents.com/en-us/news/solutions/fastening-components/bolts-vs-screws[essentracomponents]The Difference Between a Bolt and a Screw — Wilson-Garner

https://wilsongarner.com/the-difference-between-a-bolt-and-a-screw/[wilsongarner]Types of Construction Fasteners — Component Solutions Group

https://www.componentsolutionsgroup.com/blog/types-of-construction-fasteners/[componentsolutionsgroup]Understanding Bolts and Screws — FastenerMart

https://www.fastenermart.com/understanding-bolts-and-screws.html[fastenermart]