Essential Guide to Choosing the Right Bolts for Your Projects

Introduction to Bolts

- A bolt is an externally helical threaded fastener used to join materials, making it a crucial component in various projects – learn about the different types and uses of bolts to find the right one for your job.

- Bolts are tightened or released by applying torque through twisting, and they feature an external male thread that fits into a matching nut, providing a secure and efficient way to hold objects together.

- The bolt is a fundamental fastener that can be found in a variety of circumstances, from machine parts to construction projects, and is often used in combination with other fasteners like nuts, washers, and screws.

- Understanding the basics of bolts is important to ensure that you use the right one for your project, and to provide a strong and durable hold that can withstand the demands of the job.

- By choosing the right bolt, you can ensure that your project is completed efficiently and effectively, saving you time and effort in the long run.

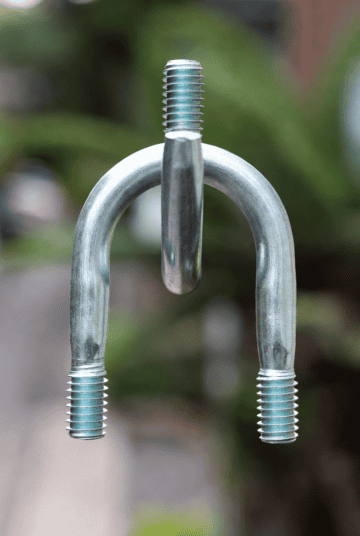

Metal bolts and nuts on white background. Fasteners equipment. Hardware tools. Stud bolt, hex nuts

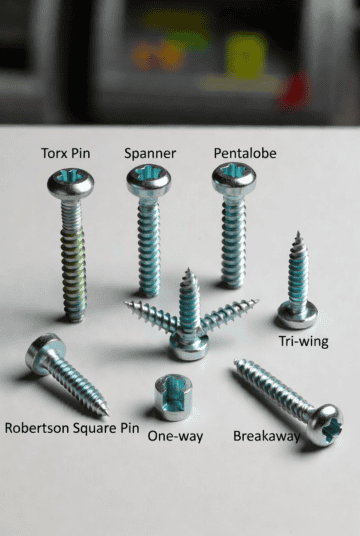

Types of Fasteners

- Fasteners come in a wide range of types, including bolts, nuts, screws, rivets, and washers, each designed for specific applications and uses.

- A one stop shop for fasteners can provide you with all the necessary components for your project, making it easier to find what you need and get the job done quickly.

- The type of fastener you choose will depend on the specific requirements of your project, including the materials being used, the load being applied, and the desired level of security.

- Steel is a common material used for fasteners, offering high strength and durability, but other materials like aluminum and brass may also be used in certain circumstances.

- By understanding the different types of fasteners available, you can make an informed decision about which one to use for your project, and ensure that you get the best results.

Bolt Characteristics

- Bolt characteristics, such as thread type and size, head type, and material, can affect the performance and suitability of the bolt for a particular application.

- The thread of a bolt is an important consideration, as it must match the nut or other component being used, and the size of the bolt will depend on the specific requirements of the project.

- The head type of a bolt can also impact its use, with different types of heads being better suited to specific tools and applications.

- The material used to make the bolt can also affect its performance, with factors like corrosion resistance and strength being important considerations.

- By considering these characteristics, you can choose a bolt that is well-suited to your project, and ensure that it provides the necessary level of performance and security.

Materials and Coatings

- Bolts can be made from a variety of materials, including steel, aluminum, and brass, each offering its own unique characteristics and benefits.

- Coatings, such as zinc or chrome, can be applied to bolts to provide additional protection against corrosion and wear, and to improve their appearance.

- The choice of material and coating will depend on the specific requirements of the project, including the environment in which the bolt will be used, and the level of security required.

- By selecting the right material and coating, you can ensure that your bolt provides the necessary level of performance and durability, and that it is well-suited to the demands of the job.

- A website or online store can provide a wide range of bolts in different materials and coatings, making it easier to find what you need and get the job done quickly.

Specialized Bolts

- Specialized bolts, such as lag bolts and eye bolts, are designed for specific applications and uses, and can provide a high level of security and performance.

- These bolts are often used in circumstances where a standard bolt would not be sufficient, such as in heavy construction or industrial applications.

- By using a specialized bolt, you can ensure that your project is completed efficiently and effectively, and that it provides the necessary level of security and durability.

- A department or stock room can provide a wide range of specialized bolts, making it easier to find what you need and get the job done quickly.

- Contact with a knowledgeable sales representative can also help you to find the right specialized bolt for your project, and to ensure that you get the best results.

Buying and Installing Bolts

- Buying bolts can be a straightforward process, especially when you have a clear understanding of what you need, and can find a one stop shop that provides all the necessary components.

- Installing bolts requires careful consideration of the specific application and use, as well as the materials being used, and the desired level of security.

- A machine or tool can be used to install bolts, and it is often necessary to use a combination of tools to get the job done efficiently and effectively.

- The availability of bolts in different sizes and types can make it easier to find what you need, and to get the job done quickly, and a website or online store can provide a wide range of bolts and fasteners.

- By following the manufacturer’s instructions and taking the necessary precautions, you can ensure that your bolts are installed correctly and provide the necessary level of performance and security.

Common Applications and Industries

Bolts are essential fasteners used across a wide range of industries and applications due to their strength, reliability, and versatility. They play a critical role in construction, automotive, machinery, aerospace, and manufacturing sectors, among others.

In construction, bolts are used to securely join steel beams, wooden structures, and concrete components, ensuring stability and safety. The automotive industry relies heavily on bolts to assemble engines, chassis, and various vehicle parts, where precision and durability are crucial.

Machinery and industrial equipment often require specialized bolts to withstand high stress, vibration, and harsh environmental conditions. Aerospace applications demand bolts made from lightweight yet strong materials to meet stringent safety standards.

Additionally, bolts are commonly found in household appliances, electronics, and furniture assembly, demonstrating their wide-ranging utility. Their availability in various sizes, materials, and coatings makes them adaptable to specific project requirements across different fields.

Understanding the common applications and industries that use bolts can help you select the right type and ensure your project meets the necessary performance and safety standards.

Future Trends in Bolts and Fasteners

As technology and industry demands evolve, the future of bolts and fasteners is shaped by advancements in materials, design, and manufacturing processes. Innovations are focused on improving strength, durability, and efficiency while reducing environmental impact.

One significant trend is the development of smart bolts equipped with sensors that monitor tension, stress, and temperature in real-time. These smart fasteners enhance safety and maintenance by providing critical data to prevent failures in critical applications such as aerospace, automotive, and infrastructure.

Sustainable materials and eco-friendly coatings are gaining popularity, aiming to reduce the carbon footprint of fasteners without compromising performance. Biodegradable and recyclable materials may become more common as industries adopt greener practices.

Additive manufacturing, or 3D printing, is revolutionizing bolt production by allowing custom designs tailored to specific applications and reducing waste. This technology enables rapid prototyping and on-demand manufacturing, which can improve supply chain efficiency.

Additionally, advancements in corrosion-resistant coatings and surface treatments are extending the lifespan of bolts used in harsh environments, such as marine and chemical industries.

By staying informed about these future trends, professionals and hobbyists alike can make better choices in selecting bolts that meet emerging performance standards and sustainability goals.