フランジねじ接続の完全ガイド:フランジねじの仕組みを理解する

はじめに

フランジ・スクリューの接続は、単なる部品の寄せ集めではありません。注意深く設計されたシステムであり、その主な役割は、強力な把持力を生み出し、維持することです。予圧と呼ばれるこの力は、ジョイントが漏れることなく、外力に対して強く保たれるための隠れた力です。多くのガイドが単に適切なパーツを選ぶことについて述べているのに対し、この記事ではより深く掘り下げています。予圧の基礎科学からトルクの使い方、より良い締め付けの方法、破損の原因の解明、適切な材料の選択まで、これらの接続が実際にどのように機能するのかを説明します。私たちのゴールは、エンジニアや技術者が基本的な組み立て作業を信頼性の高い予測可能なものに変え、ジョイントの強度を維持できるようにすることです。

関節の仕組み

フランジねじ接続をマスターするには、まずその背後にある科学を理解する必要があります。ファスナーがどのように伸びるか、加えるトルク、そして摩擦がすべて組み付けの成否に作用します。これらの基本的な考え方を理解することは、信頼性の高い接続を設計し、現場で問題を解決するために不可欠です。

プリロードコネクションの核心

その核心は、フランジ接続のネジが非常に精密で非常に硬いバネのように働くことである。ネジを締め付けると、ネジは長さ方向に伸びます。この伸びにより、ねじの内側に引っ張る力が生じ、これが予圧となります。この内部張力がフランジを引き寄せ、接合部をしっかりと保持する把持力を生み出す。この把持力こそが、コネクションの心臓部なのです。

この力は、物事を引き離そうとするすべての外力に打ち勝ち、内部の圧力を抑え、緩みの原因となる横方向の動きを防ぐのに十分な強さでなければなりません。ボルトジョイント設計の基本ルールは、開始時の予圧は、ジョイントが直面する最大使用荷重よりも常に強くなければならないということです。もし外力が把持力よりも強くなった場合、ジョイント部品は分離し、すべての荷重がボルトに伝わり、繰り返し応力による漏れや破損の可能性が高くなります。

トルクと張力の問題

予圧は欲しいものだが、レンチを使って特定のトルクをかけるのは、予圧を得ようとする最も一般的な方法だ。しかし、加えたトルクと得られるボルトの張力との関係は、間接的で無駄が多く、非常に変化しやすい。加えたトルクのエネルギーは、直接有用な予圧にはなりません。その代わり、そのエネルギーのほとんどは、さまざまな接触点での摩擦との戦いに費やされてしまうのです。典型的な無潤滑のスチール接続では、エネルギー分布は驚くほど無駄が多い:

- 入力トルクの約50%は、回転ナットまたはスクリューヘッドとフランジ表面との間の摩擦を戦う。

- 40%は、オネジとメネジ間の摩擦を防ぎます。

- 入力トルクの残り10%だけが、ボルトを伸ばして予圧を作るという有益な仕事をする。

この関係は、ナットファクター(Kファクター)という一般的な式で示されます:ここで、Tはトルク、Kはナット係数、Dはボルト径、Fは所望の予圧です。Kファクターは、すべての摩擦変数を表す数値です。典型的な無潤滑スチール・オン・スチール・ファスナーの場合、Kは0.18から0.25の範囲になります。この幅の広さが主な問題を示しています。同じトルクを入力しても、予圧出力が大きく異なることがあります。

なぜ摩擦は大きな問題なのか

トルクエネルギーの90%は摩擦によって失われるため、摩擦の変化は最終的な予圧に直接影響します。摩擦は、正確で再現性のあるグリップの大敵です。摩擦に影響を与えるものには、表面の滑らかさ、素材の硬さ、コーティングやメッキ、締め付ける速さなどがあります。

無潤滑または潤滑不良のアッセンブリーでは、"スティック・スリップ "と呼ばれる現象が起こり、締め付けプロセスがぎくしゃくすることがある。トルクがかかると、表面は一時的につかまり(スティック)、そして解放される(スリップ)。このため、正確なプリロードを得ることはほぼ不可能である。

適切な潤滑剤を使用することが、このばらつきを管理する唯一最善の方法です。指定された潤滑剤が必ずしも摩擦を減らすとは限らないが(減らす場合も多いが)、より重要なのは、摩擦係数を一定にすることである。接触面間に安定したバリアを作ることで、潤滑剤はKファクターの範囲を狭め(例えば、多くの潤滑アセンブリでは0.12から0.18)、同じトルクで締め付けられたボルトのグループ間での予圧値のばらつきを劇的に減らします。この予測可能性は、マルチボルトフランジ接続の完全性にとって極めて重要です。

フランジスクリューの設計を理解する

フランジネジ自体の物理的な設計は、接合部の性能を決定的に左右します。鋸歯状のフランジか滑らかなフランジかを選択することはランダムではなく、継手の振動に対する抵抗力、相手表面への影響、把持力がどの程度均等に分散されるかに直接影響する設計上の決定事項です。

鋸歯状フランジネジ

セレイテッド・フランジ・スクリューは、内蔵されたフランジの底部に放射状の歯が加工されています。これらのセレーションはランダムではなく、ロック機能を果たすために特定の角度で設計されています。締め付けの最終段階で、この鋭く硬い歯が接合材の表面に食い込みます。

機構はシンプルだが効果的だ。セレーションの角度は、締め付け時に比較的容易に回転させることができる。しかし、逆回転や緩みに対しては大きな機械的抵抗となる。これにより、振動による緩みの原因となる横からの力に対して非常に効果的な「ラチェット」またはロック効果が生まれます。

エンジンブロック、機械のマウント、構造フレームなど、一定の揺れで把持力を維持することが重視される高振動環境で威力を発揮する。しかし、その使用には重要な配慮が必要です。ロッキング作用は、当然ながら相手面を傷つけます。これは、塗装やコーティングが施された面や、アルミニウムのような柔らかい素材の面では受け入れがたいことです。この表面の損傷は、セレーションの食い込みによる予期せぬ摩擦のために、正確な予圧を達成することを難しくすることもある。さらに、セレーションの鋭利なエッジが使用するたびに摩耗し、ロックの精度が落ちるため、あまり再利用できない。

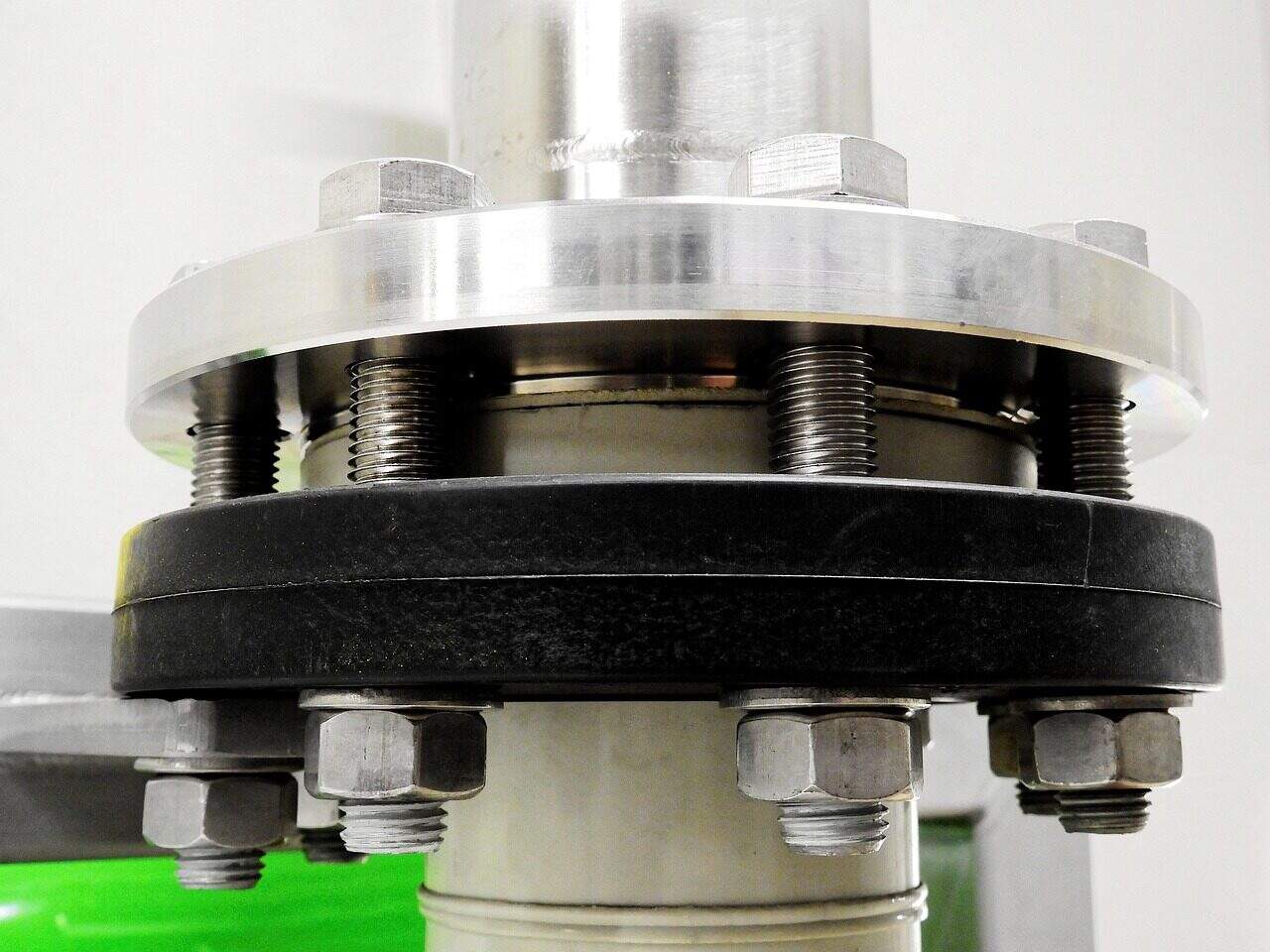

スムースフランジスクリュー

滑らかな、または非鋸歯状、フランジねじは、頭の下に平らな、途切れない軸受面を持っています。その設計目的は、その鋸歯状の対応とは根本的に異なっている。ロック機能を提供する代わりに、滑らかなフランジは、可能な限り最大の領域にわたって把持力を広げるように設計されています。

この広く均一な力の分散は、多くの用途で重要です。継手表面への応力集中を最小限に抑えることができ、繊細な素材や柔らかい素材を損傷から守るために不可欠です。主な用途は、配管システム、圧力容器、流体動力に見られるようなガスケット接合部です。ガスケット面全体に均一かつ一貫した圧力をかけることは、シールの形成と維持に不可欠です。滑らかなフランジねじは、漏れ経路につながる可能性がガスケットの局所的な押しつぶしを防止し、この均一な圧縮を保証します。

機械的なロック機能がないため、スムースフランジネジは、緩みに抵抗するために十分な予圧とネジ山の自然な摩擦に完全に依存しています。たとえ中程度の振動を伴うアプリケーションでは、長期的な接合部の完全性を確保するために、化学ネジロック剤、ロックワッシャー、または安全ワイヤなどの追加のロック機能が必要になる場合があります。

デザインの比較

鋸歯状フランジネジと平滑フランジネジのどちらを選ぶかは、耐振動性と把持力配分のトレードオフである。特定のジョイントの主要な要件に基づいて決定する必要があります。次の表は、この選択に役立つように、両者の性能特性を直接比較したものです。

表1:鋸歯状フランジネジと平滑フランジネジの性能比較

| 特徴 | 鋸歯状フランジネジ | スムースフランジスクリュー |

| 主要機能 | 耐振動性(ロック) | 均等なクランプ力配分 |

| 振動緩和 | 優れた耐性 | 劣る~まずまずの抵抗力(高い予圧が必要) |

| 表面への影響 | 火星/圧痕 合わせ面 | 表面への影響を最小限に抑える |

| 理想的なアプリケーション | エンジン、振動機械、構造フレーム | ガスケット継手、パイプフランジ、精密機器 |

| 再利用性 | 制限あり(セレーションが摩耗する可能性がある) | 高い(降伏しない場合) |

| プリロード・スキャッター | セレーションによる摩擦のため、より高くなる可能性がある。 | より低く、より予測しやすい潤滑性 |

予圧をコントロールする高度な方法

信頼性の高いボルトジョイントを得るためには、トルク値だけに頼らないことが必要です。指定されたトルクは、正確な予圧という真の目標に到達するための間接的な方法であり、出発点に過ぎません。重要なアプリケーションでは、エンジニアはボルトの張力を制御し、接続の安全性と信頼性を確保するために、より高度な戦略を用いなければなりません。

トルク仕様の枠を超える

フランジ内の複数のボルトを同じトルク仕様で締め付けた場合、各ボルトの予圧は同じにはなりません。このばらつきを予圧のばらつきといいます。ボルトごとの摩擦の違いは避けられないため、トルクだけで締め付けると、予圧のばらつきは±30%以上になりやすい。マルチボルトのフランジでは、これは重大な問題です。あるボルトは危険なほど過張力となり、永久変形を起こす危険性がある一方、他のボルトは過張力となり、繰り返し応力によって破断しやすく、潜在的な漏れの経路を作る可能性があります。高度な締め付け戦略の第一の目標は、この予圧のばらつきを最小限に抑え、継手全体にわたって均一で予測可能な把持力を確保することです。

精密クランプ戦略

トルクと張力の関係の限界を克服するために、いくつかの高度な方法が開発されてきました。これらの方法は、ボルトの伸びと予荷重により直接的な相関を得るために、摩擦という変数を制御またはバイパスしようとするものです。

- トルク・アングル方式: これは、精密クランプのための最も効果的で広く使われている戦略のひとつである。このプロセスには2つの段階がある。まず、ボルトを規定の低い「ぴったり」トルクで締め付けます。この初期トルクは、すべての接合面を完全に接触させ、隙間をなくすのに十分なトルクです。この安定した出発点から、ナットまたはスクリューの頭部に正確な追加回転角度が加えられる。その原理は、一度接合部がぴったりとはまると、回転角度とボルトの伸びの関係は、主にねじピッチの関数であるため、非常に直線的で予測可能になるというものです。この方法は、重要な張力調整段階での摩擦の影響をほとんど回避し、予圧のばらつきを±10%まで劇的に低減します。

- イールドポイントの引き締め: トルク・ツー・イールドとも呼ばれるこの方法は、与えられたボルトから最大限の把持力を引き出すように設計されています。このプロセスでは、トルクと角度の関係を監視する専用の装置を使って締め付けます。ボルトが締め付けられると、まず弾性的に伸びます。トルクの増加に比例せずに回転角度が増加し始めると降伏点が検出され、材料が塑性域に入ったことを示します。ボルトはこの点を過ぎたところで締め付けられます。これにより、可能な限り高い予圧が得られ、ジョイントが非常に緩みにくくなります。ボルトは永久的に引き伸ばされ、塑性変形を起こします。トルク・ツー・イールド・ファスナーは1回限りの部品とみなされ、決して再利用してはなりません。

- 直接張力測定: 最も重要なアプリケーションでは、ボルトの張力を直接測定することが最高レベルの精度を提供し、当て推量を効果的に排除します。方法は以下の通りです:

- ダイレクト・テンション・インジケータ(DTI): これは、ボルトに張力がかかると圧縮される小さな凹凸のある特殊なワッシャーである。技術者は、フィーラーゲージが隙間に挿入できなくなるまでボルトを締め付け、必要な最小予圧が達成されたことを示します。

- 超音波測定: これは予圧検証のゴールドスタンダードです。現場での経験から、超音波伸び計を使用することは、重要なジョイントにとって画期的なことです。このプロセスでは、ボルトの頭に小さなセンサーを取り付け、締め付ける前に長さのベースライン測定を行います。技術者がトルクをかけると、装置はボルトを通して超音波パルスを送り、飛行時間を測定し、長さの変化をリアルタイムで計算します。この長さの変化(伸び)は、予圧と計算可能な直接的な関係があります。これにより、例えばボルトの耐力75%といった目標予圧を±5%以上の精度で測定することができます。

ストレス、ひずみ、故障

フランジねじ接続は、常に応力がかかる動的システムです。これらの応力がどのように分布し、何が原因でシステムの限界を超えるのかを理解することは、耐久性の設計と故障診断の基本です。故障解析への積極的なアプローチにより、エンジニアは問題が発生する前に予防することができます。

ジョイント・ダイアグラム(VDI 2230)

ボルト接合部に作用する力を視覚化するために、エンジニアはしばしば接合ダイアグラムを参照します。このダイアグラムは、ボルトとクランプされたフランジの両方の構成要素について、力対変形をプロットしたグラフです。ボルトは比較的浅い勾配(剛性が低い)で表され、クランプ部材は一般的に短く、質量が大きいため、かなり急な勾配(剛性が高い)で表されます。

予荷重をかけた関節に外部からの引っ張り荷重が加わると、この荷重がどのように分担されるかを図が視覚的に示している。この分析によって明らかになった重要な原則は、ジョイント剛性の重要性です。クランプされた部品がボルトよりかなり硬い、よく設計されたジョイントでは、外部からの繰り返し荷重の大部分は、ボルト張力の増加ではなく、フランジ部材の減圧によって吸収されます。これにより、疲労破壊につながる大きな応力変化からボルトを保護します。VDI 2230規格は、このような相互作用を解析するための体系的な計算方法を提供し、高荷重ボルト接合部が最適な性能と安全性を持つように設計されていることを保証します。

一般的な故障モード

フランジねじ接続がなぜ故障するのかを理解することは、予防への第一歩です。故障がランダムに発生することはまれで、一般的には設計上の欠陥、誤った組み立て手順、材料と使用環境の不一致が原因です。次の表は、エンジニアや技術者が最も一般的な故障モードを特定し、それを防止するためのクイックリファレンスガイドです。

表2:フランジねじ接続の一般的な故障モード

| 故障モード | 主な原因 | 主要指標 | 予防戦略 |

| ボルト疲労 | 予圧不足;周期的な外部負荷 | ボルトの破断は、多くの場合、頭の下か、最初にかみ合ったねじ山で起こる。破断面には "ビーチマーク "が見られる。 | 予圧は、荷重によるジョイントの剥離を防ぐのに十分な高さにすること。正しい締め付け手順(トルク角など)を用いること。 |

| 振動緩和 | 低予圧;横振動またはせん断振動 | 経年変化によるクランプ力の低下、目に見えるジョイントの動き、漏れ、がたつき音。 | 機械的ロックには鋸歯状のフランジねじを使用する。予圧を最大安全レベルまで高める。 |

| ガスケットの破砕/漏れ | 予圧が過大または不均等である。 | ガスケットの損傷/はみ出し;フランジ界面からの目に見える液体/ガスの漏れ。 | 圧力、温度、媒体に適したガスケットのタイプと厚さを選択する。 |

| スレッドストリップ | 締めすぎ、ねじのかみ合い不足、異種/軟質材料の使用 | 目標トルクに達しない(ボルトが回り続ける);ねじまたはナット/穴のねじ山が剥がれる。 | かじり防止のため、適切な潤滑を行うこと。 |

| 応力腐食割れ | 腐食しやすい材料+腐食環境+引張応力 | 過負荷の明らかな兆候はないが、多くの場合、使用後にボルトに現れる脆いような亀裂。 | 適切な材料選択が重要である(次のセクションを参照)。保護コーティングを施す。可能であれば、より強度の低いボルト等級を使用して影響を受けにくくする。 |

素材と環境への影響

フランジねじ接続の長期的な完全性と安全性は、適切な材料を選択し、使用環境に適しているかどうかによって決定されます。乾燥した温度管理された部屋では完璧に機能するファスナーも、高温、腐食性化学物質、または極寒の条件にさらされると、致命的な故障を引き起こす可能性があります。環境要因の徹底的な分析はオプションではなく、責任あるジョイント設計の中核部分です。

ボルト等級と強度の適合

ボルト等級と強度の適合

フランジねじは、ISO 898-1(特性クラス8.8、10.9、12.9など)やSAE J429(グレード5、8など)のような規格で一般的に定義されている様々な強度等級で利用可能です。これらの等級は、材料の機械的特性、特に引張強さと降伏強さを示します。クラス12.9のような高グレードのボルトは、引張強さが高いため、より大きな予圧で引張ることができ、より強い接合部と高い把持力を生み出すことができます。

しかし、解決策は常に「最も強いボルトを使う」ことではありません。高強度鋼(通常クラス10.9以上)は水素脆化の影響を受けやすく、特にある種のコーティングや腐食環境が存在する場合、吸収された水素が引張荷重下で脆性破壊を引き起こす破壊メカニズムになる可能性があります。重要な工学的原則は、接合部の設計要件に適した強度を持つボルト等級を選択することです。強度を過剰に指定すると、不必要なリスクとコストが発生します。

温度の影響

極端な温度は、ファスナー材料の機械的特性に大きな影響を与えます。

- 高温: 温度が上昇すると、金属は強度と剛性を失い始めます。さらに致命的なのは、緩和やクリープと呼ばれる現象で、ボルトが一定の応力下で徐々に伸び、予圧が徐々に、しかし永久的に失われます。約250°C(480°F)以上の用途では、標準的な炭素鋼や合金鋼では不十分なことが多い。グリップ力を維持するためには、クロムモリブデン合金鋼(ASTM A193 Grade B7やB16など)やニッケル基超合金のような材料が必要になります。

- 低温(クライオジェニック): 温度が下がると、一般的な炭素鋼や合金鋼の多くは延性から脆性への遷移を起こす。靭性が失われ、衝撃や衝撃荷重を受けると脆性破壊を起こす。極低温の用途では、低温でも靭性を保つ材料が不可欠です。これには、オーステナイト系ステンレス鋼(例 えば304や316シリーズ)や特定のニッケル合金が含 まれる。

腐食:静かなる脅威

腐食は、使用中のファスナー破損の主な原因です。腐食にはいくつかの形態があり、それぞれに異なる防止策が必要です。一般的な腐食(錆)は最も一般的ですが、ガルバニック腐食(異なる金属が電解液中で接触する場合)や応力腐食割れ(SCC)のようなより危険な形態は、より大きなリスクをもたらします。適切な材料とコーティングを選択することが、第一の防御策です。以下の表は、一般的な産業環境におけるフランジネジ材料とコーティングの選択に関する実用的なガイドです。

表3:さまざまな環境に対応するフランジネジ材料/コーティングのガイド

| 環境 | キー・チャレンジ | 推奨素材 | 推奨コーティング |

| 一般室内/ドライ | 最小限の腐食リスク | 炭素鋼(クラス8.8、10.9など) | 亜鉛メッキ、リン酸塩、オイル |

| 屋外/高湿度 | 一般腐食(さび) | 炭素鋼、304ステンレス鋼 | 溶融亜鉛めっき(HDG)、亜鉛フレーク(ジオメット、ダクロメットなど) |

| マリン/塩水噴霧 | 激しい塩化腐食 | 316ステンレス鋼、二相ステンレス鋼、シリコン青銅 | 該当なし(基材の固有抵抗に依存する) |

| 化学プラント | 特定化学物質による攻撃 | ステンレス鋼(316/317L)、ニッケル合金(インコネル、ハステロイなど)、チタン | フッ素樹脂(PTFE/テフロンなど)によるバリア保護 |

| 高温 (>400°C) | 弛緩, 酸化, 高温腐食 | 合金鋼(A193 B16など)、ニッケル合金(インコネル718など) | セラミックベースのコーティング、銀メッキ(焼き付き防止として) |

結論完全なシステム・アプローチ

信頼性の高いフランジねじ接続は、単一の部品に集中することによって達成されるのではなく、設計されたシステム全体を理解し、制御することによって達成されます。その成功は、機械物理学の深い理解、正確な組み立て手順、正しい部品の選択、そしてスマートな材料科学を組み合わせた完全なアプローチの結果です。単純なトルク仕様では不十分であり、真のジョイント・インテグリティには、より厳密な方法論が要求されます。

この分析から最も重要な3つの教訓を忘れてはならない:

- 正確で十分な予圧を得ることが最も重要な目的であり、この把持力こそが関節の性能を保証するものだからです。

- フランジネジの物理的設計は、耐振動性であれ、均一な荷重分布であれ、アプリケーションの主な要求に意図的に適合させなければならない。

- 接続は完全なシステムであり、操作上のストレス、材料の適合性、環境の長期的影響を考慮して設計されなければならない。

この完全なシステム・アプローチを採用することで、一般的な組み立て作業を、予測可能で信頼性が高く、安全なエンジニアリングの成果へと高め、耐用年数を通じて接続部の完全性を保証します。

- ファスナー規格とエンジニアリング - ASTM International https://www.astm.org/

- ボルトジョイント設計 - VDI (Verein Deutscher Ingenieure) https://www.vdi.de/

- メカニカルファスナー - Wikipedia https://en.wikipedia.org/wiki/Bolted_joint

- ファスナーとボルトの規格 - ISO https://www.iso.org/

- 機械工学規格 - ASME https://www.asme.org/

- 工業ファスナー協会 https://www.industrial-fasteners.org/

- ファスナー技術 - ScienceDirect https://www.sciencedirect.com/topics/engineering/bolted-joint

- 製造とファスニング・システム - SME https://www.sme.org/

- 工業用ファスナーおよびコンポーネント - Thomasnet https://www.thomasnet.com/

- 機械工学教育 - MIT OpenCourseWare https://ocw.mit.edu/

ボルト等級と強度の適合

ボルト等級と強度の適合