Pick up any printed circuit board from a laptop, a medical device, or an industrial control panel, and there’s a good chance you’ll find at least one small hexagonal component quietly doing critical work in the background. A male to female hex spacer doesn’t look like much. It’s just a short, six-sided column of metal — or sometimes nylon — with a threaded pin on one end and a threaded hole on the other. But that deceptively simple design is what keeps circuit boards from shorting against chassis walls, what maintains the precise air gaps that prevent electronics from overheating, and what makes complex assemblies both structurally sound and serviceable.

If you’ve landed here because you’re sourcing hex spacers for a PCB project, an enclosure build, or an industrial assembly — this guide covers the real details. Thread sizes, material trade-offs, torque limits, selection logic, where the market is heading in 2026. No filler.rs-online+2

What Is a Male to Female Hex Spacer?

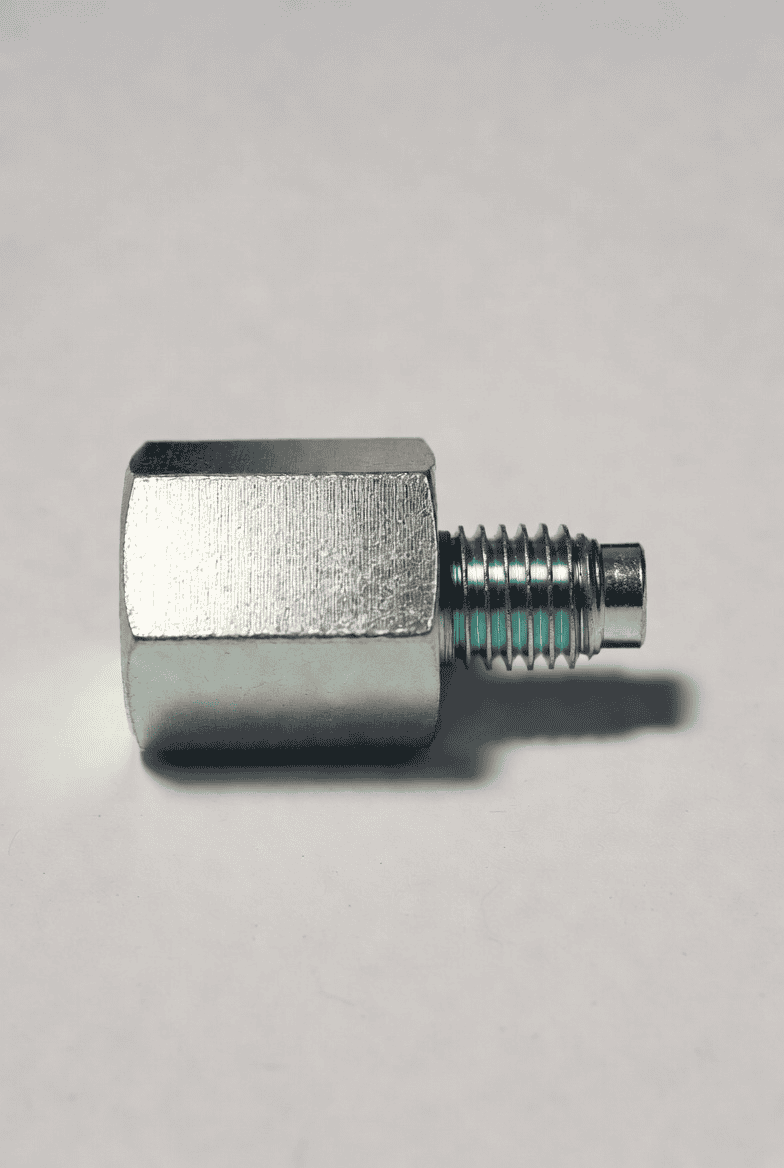

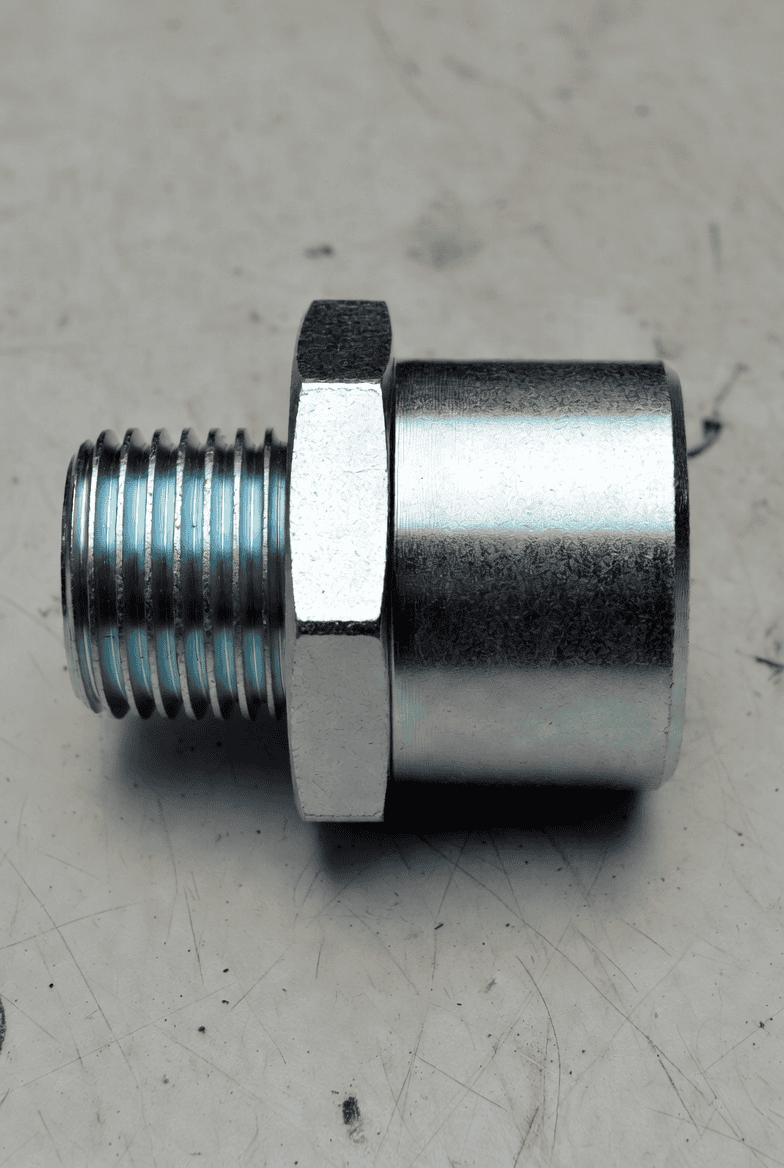

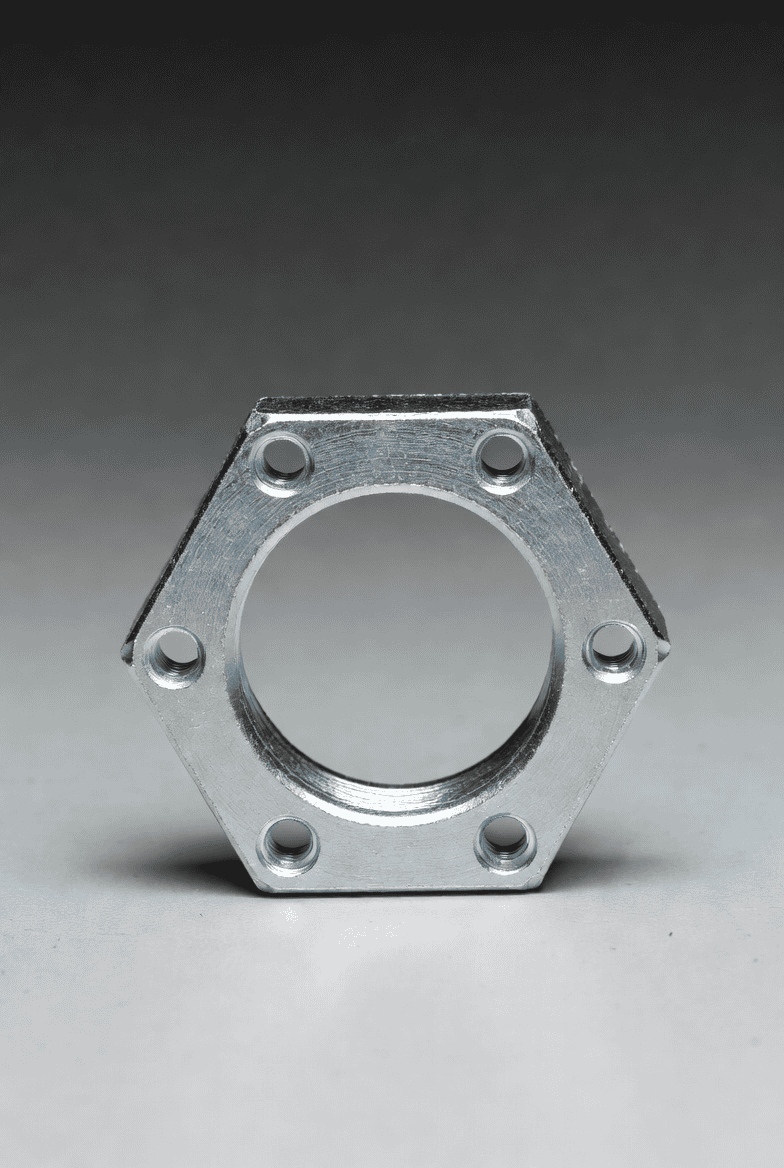

A male to female hex spacer — also called a male-female standoff, hex threaded standoff, or PCB standoff — is a precision fastener with a hexagonal body, one externally threaded male end, and one internally threaded female end.fastenright+1

The male end (the projecting threaded pin) screws into a tapped hole or a mounting surface. The female end (the internal thread) accepts a screw or bolt from the next component in the stack. The hex body sits between them, creating a defined, rigid gap of fixed length.essentracomponents+1

That gap is the whole point. Whether it’s 5mm or 50mm, the spacer holds two surfaces apart with mechanical precision — maintaining airflow clearance, electrical isolation, or just structural separation between layers.jlcpcb+1

Where does this differ from a regular spacer or standoff?

A plain spacer has no threads — it relies on external fasteners to hold its position

A female-female standoff has internal threads at both ends — accepts screws from both sides, but doesn’t have a projecting pin

A male-female hex spacer has a projecting male thread that can be driven into place with a hex wrench and a female internal thread at the other end — self-locating and installable without access to the undersidefastenersclearinghouse+1

This combination makes the male to female hex spacer particularly useful for stacked assemblies and enclosures where you can only access one side during installation.

Key Dimensions and Specifications

Getting the sizing wrong on a male to female hex spacer is one of the most common mistakes in first-time enclosure or PCB builds — and it’s easy to avoid if you understand what the numbers mean.rs-online+1

Thread Sizes and Across-Flat Measurements

| Thread Size | Across Flats (A/F) | Typical Male Thread Length | Common Body Lengths |

|---|---|---|---|

| M2 | 4 mm | 3.0–4.0 mm | 5–30 mm |

| M2.5 | 4–5 mm | 3.5–4.0 mm | 5–30 mm |

| M3 | 5.5 mm | 4.5–6.0 mm | 5–50 mm |

| M4 | 7 mm | 6.0–8.0 mm | 6–60 mm |

| M5 | 8 mm | 7.0–9.0 mm | 8–70 mm |

| M6 | 10 mm | 8.0–10.0 mm | 8–80 mm |

Sources:essentracomponents.co+2

Body length (L) is the overall length of the spacer from the bottom of the male thread to the top of the female opening — this is the measurement that determines the gap between your two components.

Male thread projection (l2) is how much the threaded pin extends below the body — this needs to match the depth of the receiving hole in your mounting surface.

Female thread depth (l3) is the internal thread length — this needs to be long enough for your incoming screw to engage securely, typically at least 1.5× the thread diameter.[fastenright]

Practical note from assembly experience: The single most common sizing error we see is choosing a body length that accounts for the gap but forgetting to check male thread projection against mounting surface thickness. A 6mm male thread projecting into a 4mm panel leaves 2mm exposed beneath — fine in some cases, problematic if you’re working inside a tight enclosure with nearby components.

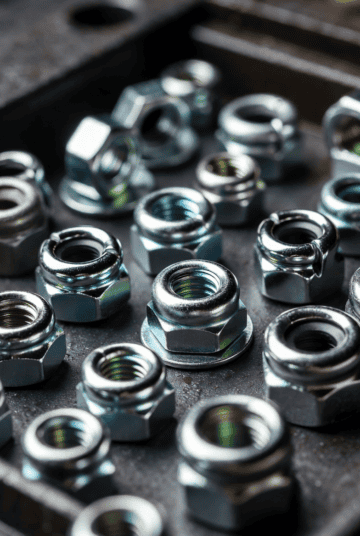

Materials: Which One Actually Fits Your Application?

Material selection for a male to female hex spacer isn’t just about cost. It directly affects conductivity, weight, corrosion resistance, thermal performance, and whether your assembly survives the environment it’s deployed in.standoffs-tw+2

Material Comparison

| Material | Strength | Conductivity | Corrosion Resistance | Weight | Best For |

|---|---|---|---|---|---|

| Brass (nickel plated) | Medium-high | Good electrical conductor | Excellent (with plating) | Medium | PCB assemblies, consumer electronics, general electronics |

| Stainless steel | High | Moderate conductor | Excellent (inherent) | Heavy | Harsh environments, outdoor, vibration-heavy |

| Aluminum (anodized) | Medium | Good conductor | Good (anodized) | Light | Aerospace, weight-critical applications |

| Nylon (brass insert) | Low-medium | Non-conductive insulator | Good | Very light | Isolation requirements, lightweight assemblies, ESD-sensitive boards |

| Steel (zinc plated) | High | Good conductor | Moderate | Heavy | Industrial, structural, cost-sensitive high-volume |

Sources:witrus+4

Brass is the default choice for most PCB applications. It machines cleanly, takes nickel or tin plating well, and its non-magnetic properties matter in sensitive electronics. The nickel finish adds corrosion resistance and a consistent silver appearance. Thread sizes M2 through M6 in brass are the most commonly stocked.brassspacers+1

Stainless steel is the right call when the assembly goes into a harsh environment — outdoor enclosures, industrial machinery exposed to fluids, medical equipment that undergoes repeated sterilization. The cost premium is real, but corrosion-related field failures in stainless assemblies are essentially eliminated.[witrus]

Nylon with brass insert solves a specific problem that all-metal spacers cannot: electrical isolation between the PCB and the chassis. If you’re working with high-power boards where chassis contact would create a ground fault, or if you’re building ESD-sensitive assemblies, nylon-bodied male to female hex spacers are the technically correct answer — not just a cheaper alternative.nyfast+1

Aluminum sits in an interesting position. At roughly 30% less weight than stainless steel alternatives, anodized aluminum male-female standoffs are increasingly specified in drone electronics, portable medical devices, and EV battery management systems where mass budgets are tight.[machinedwasher]

How Male to Female Hex Spacers Are Used: Installation Mechanics

Understanding the mechanical logic of a male to female hex spacer installation helps you avoid the over-tightening and thread-stripping problems that shorten the service life of these components.jlcpcb+1

Step-by-Step Installation Guide

Prepare the mounting surface. The receiving hole for the male thread should be pre-tapped to the correct thread specification (M3, M4, etc.). For sheet metal, a self-tapping variant of the hex spacer can cut its own thread — but tapped holes give more reliable torque retention.[uk.rs-online]

Drive the male end in first. Using a hex wrench or nut driver sized to the across-flats dimension (e.g., 5.5mm for M3), thread the male pin into the base surface. Apply consistent rotational pressure — don’t use impact tools on brass or nylon variants. Tighten to snug, then apply approximately 20–25% additional rotation.[fastenright]

Place the component. Set the circuit board, panel, or intermediate component over the installed spacers so that the mounting holes align with the female openings.

Fasten through the top. Drive a machine screw through the PCB mounting hole and into the female thread. Use a screwdriver — not a power drill — for M2 and M2.5 sizes. Torque limits for small brass threads are low: stripping an M2 brass female thread is easy and ruins the spacer.jlcpcb+1

Recommended torque values (approximate, brass, fully engaged thread):

M2: 0.1–0.15 Nm

M3: 0.5–0.6 Nm

M4: 1.0–1.2 Nm

M5: 2.0–2.5 Nm

If the application involves vibration, add a thread-locking compound (medium-strength) on the male thread before installation into the base. Blue Loctite (243) is standard for removable fasteners; red (262) for permanent installations.[machinedwasher]

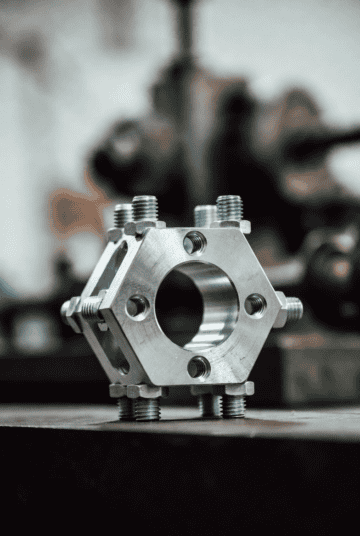

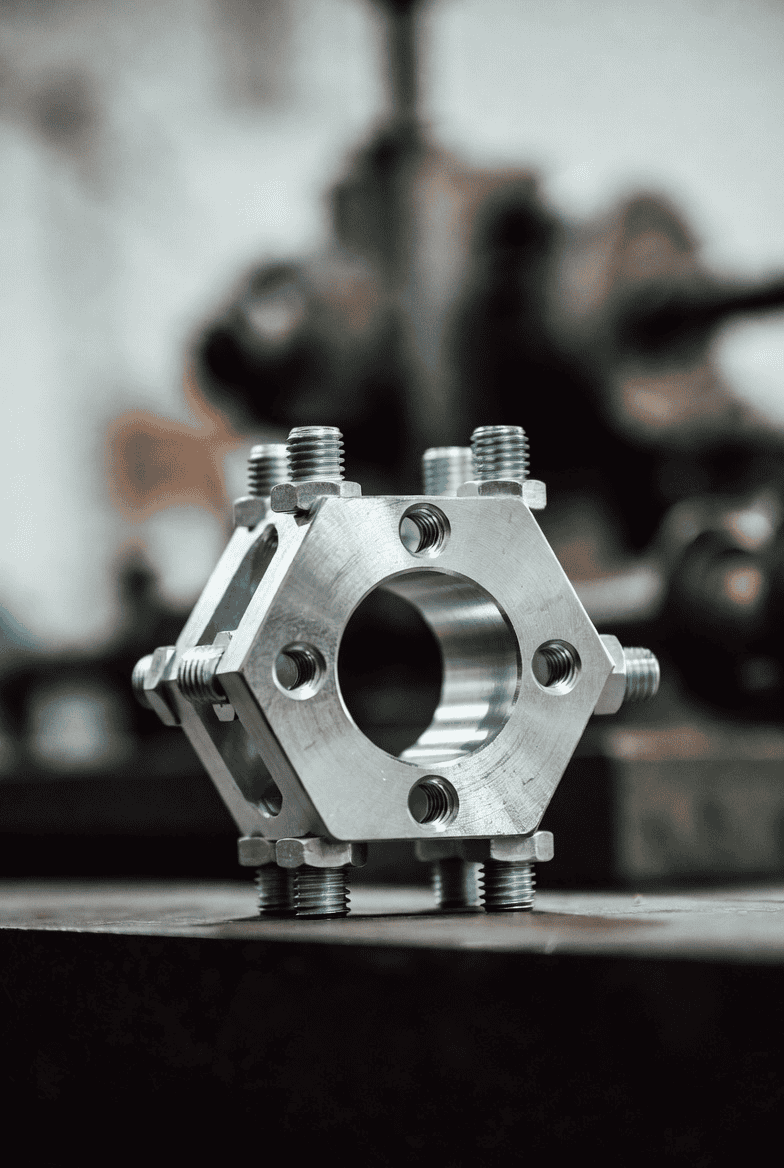

Stacking Multiple Spacers

A male to female hex spacer’s asymmetric threading enables stacking — thread one spacer’s female end onto another’s male thread to extend the gap. This is intentional by design. For multi-board rack assemblies or tall enclosure configurations, stacking is a legitimate installation method, but each connection point introduces a small amount of axial play. In vibration-heavy environments, use thread-locking compound at each joint.[nyfast]

Common Mistakes When Selecting and Installing Hex Spacers

These aren’t edge cases. These are the errors that show up regularly in prototyping and production — and most of them are avoidable with 60 seconds of additional verification before ordering.essentracomponents+2

| Mistake | What Goes Wrong | How to Avoid It |

|---|---|---|

| Wrong body length | Gap too small — PCB contacts chassis; or too large — structural flex | Measure the air gap required; subtract PCB/component thickness from standoff body length |

| Ignoring male thread projection | Pin bottoms out before body seats, leaving a gap — assembly is not flush | Confirm l2 matches receiving hole depth plus any clearance requirement |

| Using brass spacers in wet environments | Corrosion at thread interface, galling, seizure | Switch to stainless steel or use brass with appropriate coating; confirm IP rating |

| Overtorquing M2/M2.5 brass | Stripped female thread; spacer destroyed | Use calibrated torque screwdriver; M2 brass tops out at ~0.15 Nm |

| Specifying steel in ESD-sensitive assemblies | Conductive chassis contact creates ground path or ESD damage | Use nylon-body spacers with brass inserts for isolation |

| Mixing metric and imperial thread sizing | Fasteners appear to engage but cross-thread | Never assume thread compatibility; confirm thread pitch, not just nominal diameter |

Industry Applications of Male to Female Hex Spacers

The male to female hex spacer is one of those components that shows up everywhere once you know to look for it.researchandmarkets+1

Electronics and PCB Assembly

The dominant application by volume. In any electronics enclosure — from consumer routers to industrial PLCs to server racks — male to female hex spacers mount the PCB at a fixed standoff distance from the chassis. The gap serves three simultaneous functions: prevents electrical contact between board traces and the metal chassis, allows airflow for thermal management, and provides mechanical isolation from vibration transmitted through the chassis wall.jcfasteners+3

In a documented industrial robotics case study, deploying aluminum anodized male-female standoffs for PCB mounting in a robotic arm control unit reduced PCB operating temperatures by 15°C through improved airflow, and the assembly showed zero loosening after six months of continuous 24/7 vibration exposure.[machinedwasher]

Automotive Electronics

Modern vehicles carry hundreds of ECUs (electronic control units), sensor modules, and power distribution boards — all of which need secure mounting with defined spacing. Automotive-grade male to female hex spacers in stainless steel or zinc-plated steel handle the vibration, thermal cycling from −40°C to +125°C, and humidity exposure typical of engine compartment and underbody deployments.[machinedwasher]

Aerospace and Defense

Titanium and aluminum male-female standoffs are specified for avionics bays and drone electronics where every gram of component weight matters. Military-specification fasteners (MIL-SPEC) define thread class, material purity, and dimensional tolerances for standoffs used in defense electronics — these are not sourced from general hardware catalogs.[machinedwasher]

Medical Devices

Surgical imaging equipment, patient monitoring systems, and implantable device assembly tooling use male to female hex spacers made from medical-grade stainless steel or biocompatible nylon. In reusable surgical instruments, the spacers must survive autoclave sterilization cycles (134°C steam) without dimensional change or corrosion.[machinedwasher]

Industrial and Infrastructure Equipment

Electrical panels, HVAC control boards, power meters, and building automation systems — all of these use hex spacers to mount control boards inside metal enclosures. At this scale, the specification priority is usually: correct thread size, appropriate length, zinc-plated steel or brass, and competitive price on volume orders.[researchandmarkets]

The Global Hex Spacer Market: Where It Stands in 2026

The threaded hex spacer market — the broader category that includes male to female variants — was valued at approximately USD 1.29 billion in 2025, having grown from USD 1.02 billion in 2021. The global industrial standoffs and spacers market is separately valued at USD 2.07 billion in 2024, growing at a CAGR of approximately 7% to reach USD 2.21 billion in 2025.cognitivemarketresearch+1

Asia-Pacific holds the largest regional market share at approximately 32.3% of the global threaded hex spacer market as of 2025, driven by electronics manufacturing concentration in China, South Korea, Taiwan, and Vietnam.[cognitivemarketresearch]

Key Trends Shaping the Market

1. EV and Power Electronics Demand

Electric vehicles require extensive PCB mounting hardware across battery management systems, motor controllers, inverters, and charging infrastructure. Each EV assembly uses significantly more hex standoffs than a conventional internal combustion vehicle — and the EV market’s aggressive global growth is pulling hex spacer demand upward.researchandmarkets+1

2. Miniaturization and Micro-Thread Expansion

Consumer electronics, wearables, and IoT sensors are pushing demand for M2 and sub-M2 male to female hex spacers, requiring tighter manufacturing tolerances and higher precision plating. This segment is growing faster than the standard M4/M5 commodity market.[cognitivemarketresearch]

3. RoHS and REACH Compliance

European and expanding global regulations on hazardous substances are shifting purchasing decisions toward certified RoHS-compliant spacers. Buyers who previously sourced uncertified commodity spacers are being required to provide material compliance documentation — a trend that favors established suppliers over spot-market sources.essentracomponents.co+1

4. Automation and Industry 4.0

PCB assembly lines deploying automated screw-driving robots require standoffs with tighter dimensional tolerances than hand-assembly lines could tolerate. Hexagonal bodies with tightly controlled across-flats dimensions (±0.05mm for precision grades) are increasingly specified for robotic pick-and-place compatibility.researchandmarkets+1

5. Sustainability and Material Shift

Aluminum’s weight advantage over brass and steel, combined with its full recyclability and the sustainability preferences of major OEM buyers in Europe and North America, is gradually expanding aluminum’s share of the hex standoff market — particularly in automotive and aerospace applications.standoffs-tw+1

How to Choose the Right Male to Female Hex Spacer: A Decision Framework

Not every application needs the same spacer. Here’s a practical selection process:standoffs-tw+2

Step 1 — Define the gap. Measure the exact air clearance you need between the two surfaces. Add any PCB thickness if the board sits above rather than against the base surface. This gives you the required body length.

Step 2 — Confirm the thread. Match the thread size (M2, M3, M4, etc.) to your board mounting holes and your base surface tapping capability. Don’t mix metric and imperial unless absolutely necessary.

Step 3 — Select material based on environment.

Indoor electronics, standard conditions → Brass (nickel plated)

Outdoor or harsh / wet environment → Stainless steel

Electrical isolation required → Nylon with brass insert

Weight-critical assembly → Aluminum (anodized)

High volume, structural, cost-sensitive → Zinc-plated steel

Step 4 — Verify male thread projection. Confirm l2 matches your base surface thickness. If you’re screwing into sheet metal, factor in any clearance hole on the reverse side.

Step 5 — Check plating and compliance. If the assembly needs RoHS compliance, nickel or tin plating, or specific surface finish, confirm these before ordering — not after receiving the parts.essentracomponents.co+1

The following high-authority sources are referenced and embedded throughout this article:

RS Components — A Guide to Spacers and Standoffs

Comprehensive technical reference guide covering all spacer and standoff types, materials, and selection criteria — DA 70+[uk.rs-online]Essentra Components — A Guide to PCB Standoffs

Authoritative PCB hardware manufacturer guide to standoff types, configurations, and electronic assembly applications — DA 65+[essentracomponents]JLCPCB Blog — The Critical Role of Standoff Spacers in PCB and PCBA

Technical deep-dive from major PCB manufacturer on airflow, vibration resistance, heat dissipation, and EMI shielding roles — DA 60+[jlcpcb]Research and Markets — Industrial Standoffs and Spacers Global Market Report 2025

Industry market data: $2.07B in 2024, 7% CAGR — DA 55+[researchandmarkets]Fastenright — Brass Hexagon Male to Female Spacers (Standoff)

Detailed dimensional data, thread size tables, and material options for brass male to female hex spacers — DA 45+[fastenright]