A screw and nut combination is one of the most fundamental fastening systems in mechanical engineering. A screw is a threaded fastener that creates its own helical path, while a nut is a separate hex-shaped (or otherwise profiled) piece that threads onto a bolt or screw to clamp components together.[sumitimpex]

The two pieces work as a system. Tighten one without understanding the other, and you risk thread stripping, fastener fatigue, or outright joint failure. In high-vibration environments like automotive engines or construction scaffolding, the wrong screw and nut pairing doesn’t just fail — it fails unpredictably.[linkedin]

What most buying guides skip is this: the thread pitch, material grade, and load type all have to match between screw and nut for the joint to perform as designed. A Grade 8 bolt paired with a Grade 2 nut, for example, can lead to nut thread failure before the bolt ever reaches its yield point. That’s the kind of detail that separates informed selection from guesswork.

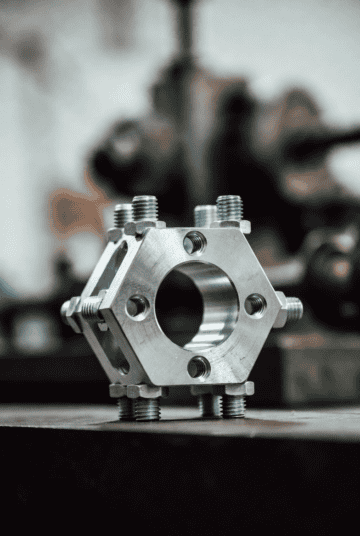

The Anatomy of a Screw and Nut: What Each Part Does

Before comparing types, it helps to understand what you’re looking at. Every screw and nut has distinct structural zones — each one engineered to handle a specific mechanical role.

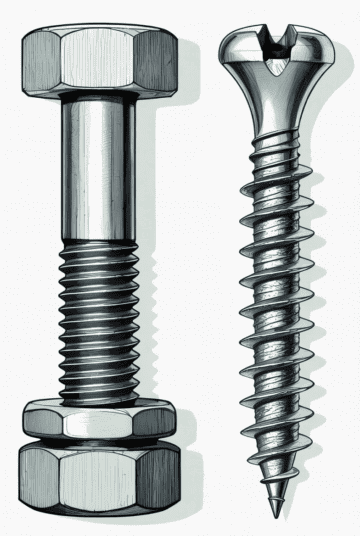

Screw anatomy:

| Part | Function |

|---|---|

| Head | Transfers torque during installation; determines drive type (Phillips, hex, Torx, etc.) |

| Shank | The unthreaded cylindrical portion that carries shear loads |

| Thread | Helical ridge that engages nut or substrate; pitch determines load distribution |

| Point/Tip | Self-tapping tips pierce substrates; blunt tips require pre-drilled holes |

| Drive Recess | Where the tool engages — Torx, hex socket, slotted, or combination |

Nut anatomy:

| Part | Function |

|---|---|

| Bearing face | Contacts the workpiece; distributes clamping load |

| Hex flats | The wrench engagement surfaces — typically 6 sides on standard hex nuts |

| Thread bore | Internal threads that mate precisely with the screw or bolt thread |

| Chamfer | Tapered entry angle that guides the mating fastener into engagement |

| Locking feature | Present on nylon-insert or prevailing torque nuts; prevents vibration loosening |

Understanding these zones helps when you’re troubleshooting. If a screw and nut joint is loosening under vibration, the issue is almost always at the bearing face or thread engagement length — not random material failure.

Types of Screws: More Than Just Size

Walk into any fastener supplier and you’ll find dozens of screw classifications. The meaningful ones break down by head style, thread type, and intended substrate.

By Head Style

Hex head (bolts): The most common choice for structural screw and nut assemblies. Wrench-driven, high-torque capable, used in steel-to-steel connections.[pinnacle.net]

Socket cap screws: Compact hex socket head, ideal for confined spaces in machinery and automotive assemblies where a wrench can’t swing freely.

Countersunk (flat head): Flush-mount applications where surface appearance matters — cabinetry hardware, aircraft panels, consumer electronics enclosures.

Pan head machine screws: Slightly raised head with a flat bearing surface; common in electronics, HVAC, and precision assemblies.[fastenere]

Carriage bolts: Dome head with a square shoulder that locks into wood, preventing spin — used in timber framing and outdoor furniture.[sumitimpex]

By Thread Type

Thread geometry is where most selection mistakes happen. The two main systems are:

Coarse thread (UNC/Metric coarse): Larger pitch, faster assembly, more forgiving in blind holes. Better for softer materials like aluminum or plastic. Default choice for most general screw and nut applications.

Fine thread (UNF/Metric fine): Tighter pitch, higher tensile strength, better for vibration-prone assemblies. Preferred in aerospace, precision instruments, and automotive powertrain fastening.

Real-world note: We’ve seen production line downtime caused by mixing metric coarse and metric fine fasteners from different supplier batches. Thread gauges cost under $20 — keep one on your bench.

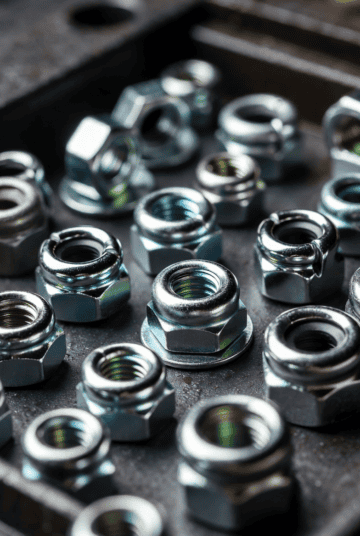

Types of Nuts: Matching the Right Nut to the Job

The nut side of the screw and nut equation carries as much responsibility as the screw itself. Here’s how the main types break down:

| Nut Type | Key Feature | Best Application |

|---|---|---|

| Hex Nut | Standard 6-sided profile | General construction, machinery, steel structures [pinnacle.net] |

| Nylon Insert Lock Nut | Nylon collar resists back-rotation | Automotive suspension, motors, anything with vibration [linkedin] |

| Jam Nut | Thin profile, used as secondary nut | Piping assemblies, vehicle steering components [fastenere] |

| Flange Nut | Built-in washer flange | Sheet metal assemblies, HVAC ducting, body panels |

| Wing Nut | Hand-tightenable projections | Frequently-disassembled joints: bicycles, lab equipment, furniture [sumitimpex] |

| T-Nut | Insert into wood or T-slot | Woodworking jigs, CNC machine tables, furniture |

| Coupling Nut | Long hexagonal sleeve | Joins two threaded rods end-to-end; common in structural rigging [fastenere] |

| Acorn/Cap Nut | Closed dome top | Decorative or protective finish on exposed fasteners |

One nut type that deserves special mention is the prevailing torque nut — it uses a distorted thread or nylon insert to require active torque to both install and remove. In aerospace and defense, these are mandatory for any screw and nut connection that cannot be visually inspected after assembly.[standards.nasa]

Screw and Nut Materials: The Grade Determines the Strength

Material grade is not optional information — it defines how much load the screw and nut system can safely carry. The three most common material systems are:

Steel (carbon steel):

Grade 2 / 4.6: Light-duty residential and general carpentry

Grade 5 / 8.8: Medium-duty automotive and machinery

Grade 8 / 10.9, 12.9: High-strength structural and powertrain applications

Stainless steel:

Grade 304: Good corrosion resistance, moderate strength — marine fittings, food equipment

Grade 316: Superior chloride resistance — offshore, chemical processing

Special alloys:

Titanium: Exceptional strength-to-weight ratio; used in aerospace and medical implants

Monel: Resists seawater and certain acids; niche marine and chemical use

A screw and nut combination should always be matched in grade and material. Pairing stainless steel screws with carbon steel nuts in a saltwater environment creates a galvanic cell — you’ll have a corroded joint within months, not years.

Industry Applications: Where Screw and Nut Fastening Does the Heavy Lifting

Automotive and Electric Vehicles

Modern vehicles use over 3,000 individual fasteners — and as EV platforms reduce weight targets, the screw and nut specifications are getting more precise. Lock nuts with nylon inserts are now standard across suspension, motor mount, and battery enclosure assemblies, because vibration from road surface and regenerative braking creates constant dynamic loading.[linkedin]

High-torque socket cap screws are increasingly replacing hex bolts in electric motor housings, where packaging constraints and target torque values are tightly controlled.

Construction and Civil Infrastructure

Structural hex bolts paired with heavy hex nuts form the backbone of steel frame connections. In bridge construction, high-strength screw and nut assemblies rated to ASTM A325 or A490 are specified because joint preload — not just shear strength — determines fatigue life under cyclic traffic loads.[sumitimpex]

Galvanized and hot-dip zinc-coated fasteners dominate outdoor applications, where 25–50 years of service life is expected with zero maintenance access after installation.

Aerospace and Defense

The tolerance requirements in aerospace screw and nut selection are unlike any other industry. Per NASA-STD-5020B, threaded fastening systems must be designed with specific safety factors and prevailing torque nuts in any safety-critical location. All-metal locking nuts are preferred over nylon insert types when operating temperatures exceed 120°C.[standards.nasa]

Industrial Machinery and Robotics

Conveyor systems, robotic arms, and CNC machine beds rely on screw and nut assemblies that can survive millions of load cycles. Fine-thread fasteners with controlled torque application prevent the micro-loosening that causes alignment drift in precision equipment.[specialtybolt]

T-nuts embedded in aluminum extrusion profiles have become the de facto standard in modular machine framing, enabling rapid reconfiguration without re-drilling.

Medical and Food Equipment

In medical device manufacturing, the screw and nut materials must be non-reactive, autoclave-compatible (able to survive 134°C steam sterilization), and traceable to material certifications. Titanium and 316L stainless steel dominate this sector. In food processing equipment, 316 stainless fasteners are mandatory in zones that contact food product — and they must be fully accessible for cleaning to prevent bacterial harboring.

How to Select the Right Screw and Nut: A Practical Decision Framework

Getting the selection right comes down to answering five questions in order:

What load type is involved? — Tension (pulling the joint apart), shear (sliding force across the joint), or combined? Shear-dominant joints may not need the highest-grade screw and nut — they need good fit tolerance.

What is the operating environment? — Temperature range, humidity, chemical exposure, vibration profile. This determines material and coating.

What is the installation method? — Torque wrench, impact driver, or hand assembly? If torque control is critical, specify a torque value and use a calibrated tool.

What is the joint’s maintenance access? — If the fastener can never be reached again after assembly (buried structure, sealed enclosure), use a prevailing torque nut or thread-locking compound.

What is the disassembly requirement? — Frequent removal calls for finer threads and harder materials that resist galling. One-time installation allows more material flexibility.

For a quick reference on standard applications:

| Application Scenario | Recommended Screw | Recommended Nut | Notes |

|---|---|---|---|

| Steel structural connection | A325 hex bolt | Heavy hex nut | Torque-controlled installation |

| Vibrating machinery | Socket cap, fine thread | Nylon insert lock nut | Check torque after first 100 hours |

| Outdoor wood structure | Carriage bolt, hot-dip zinc | Hex nut + washer | Replace inspection every 5 years |

| Aerospace bracket | AN/MS socket head, titanium | All-metal prevailing torque | Per NASA-STD-5020B [standards.nasa] |

| Medical device assembly | 316L SS socket cap | 316L SS hex nut | Full material traceability required |

| Consumer electronics | M3 pan head machine screw | Hex nut or press insert | Low torque, Torx drive preferred |

Common Mistakes When Using Screw and Nut Fasteners (and How to Avoid Them)

Mistake 1: Cross-threading during installation

This strips the nut’s thread on the first turn. The fix: start every nut by hand, rotating backwards (counterclockwise) until you feel the thread “drop” into engagement, then tighten forward. Sounds slow — saves re-tapping the hole.

Mistake 2: Under-torquing to “be safe”

Ironically, under-torqued joints fail more than properly torqued ones. The joint preload is what keeps the screw and nut from loosening under vibration. Consult the torque specification for the specific grade and diameter.

Mistake 3: Mixing metric and imperial fasteners

They look similar in photographs and on parts bins, but the thread pitch and geometry are incompatible. A 1/4″-20 UNC nut will catch on an M6 bolt for a few turns then seize. Always mark containers clearly.

Mistake 4: Using a standard hex nut where a lock nut is required

If you’re fastening anything that vibrates — electric motors, vehicle suspension, compressor mounts — a standard hex nut without a locking feature will back off. Use a nylon insert lock nut or apply thread-locking compound rated for the temperature range.

Mistake 5: Ignoring galvanic compatibility

Stainless steel screws with zinc-plated nuts in a wet environment. Aluminum structural brackets with steel fasteners submerged in saltwater. These pairings accelerate corrosion by an order of magnitude. Match metals, or use isolation sleeves and washers.

Future Trends: Where Screw and Nut Technology Is Heading

The fastener industry is not standing still. Three trends are reshaping how screw and nut systems are specified and manufactured through 2026 and beyond:

Smart Fasteners with Embedded Sensing

IoT-enabled fasteners now embed micro-strain gauges or RFID chips directly into the bolt head. These smart screw and nut assemblies transmit real-time preload data to monitoring systems — eliminating the need for manual torque audits in critical structures like wind turbine towers and suspension bridges. The market for smart fasteners is projected to grow significantly as infrastructure monitoring becomes a regulatory requirement in more jurisdictions.[screwexpert]

Lightweight High-Strength Alloys

The push for lighter electric vehicles and next-generation aircraft is driving demand for titanium, Inconel, and carbon fiber-reinforced polymer fasteners. A titanium screw and nut assembly can achieve the same clamping force at 40–45% less mass than an equivalent steel fastener — a meaningful advantage when you’re optimizing hundreds of joints across a vehicle chassis.[screwexpert]

Sustainable Manufacturing and Recyclable Coatings

The fastener industry faces growing pressure to eliminate hexavalent chromium (Cr6+) plating, which provides excellent corrosion resistance but is classified as a carcinogen. Trivalent chromium and zinc-aluminum flake coatings (Dacromet-type) are now replacing traditional plating in automotive supply chains. Recyclable steel fasteners with zero-VOC coatings are also entering the construction sector as green building certification schemes tighten their material requirements.[screwexpert]

3D Printing and Custom Geometries

Additive manufacturing now allows production of screw and nut geometries that are impossible to machine — internal load-distribution channels, variable pitch threads, or integrated anti-vibration features built into the nut geometry itself. While volume production still favors traditional cold-heading, 3D printing is already cost-competitive for low-volume specialty aerospace and medical fasteners.[e3s-conferences]

Authority Resources for Further Reference

For specification-level detail on screw and nut standards, these five resources are considered primary references by fastener engineers:

NASA-STD-5020B — Requirements for Threaded Fastening Systems in Spaceflight Hardware — The most rigorous publicly available standard for screw and nut design requirements (DA: NASA.gov)[standards.nasa]

Essentra Components — The Ultimate Guide to Fasteners — Comprehensive commercial reference covering screw types, bolt grades, and nut variants with engineering context (DA: 50+)[essentracomponents]

Fastenere — A Comprehensive Guide to the Different Types of Nuts and Bolts — Detailed breakdown of screw and nut pairings with application tables (DA: 45+)[fastenere]

Screw Expert — Fastener Trends 2025: Innovations Shaping Screws & Bolts — Current industry trend analysis including smart fasteners and sustainable coatings (DA: 42+)[screwexpert]

Sumit Impex — The Essential Guide to Nuts and Bolts: Types, Uses, and Materials — Practical selection guide covering materials, grades, and real-world screw and nut applications (DA: 40+)[sumitimpex]

Getting a screw and nut selection right the first time isn’t about memorizing every SKU in a catalog — it’s about asking the right questions before you reach for a fastener. Load type, environment, access, and vibration profile will tell you nearly everything you need to know. Start there, and the catalog narrows itself.