You’ve tightened one today. You probably didn’t notice. Screws hold together your desk chair, your laptop casing, the shelf above your bed, and the engine in your car. They’re everywhere — and yet most people couldn’t precisely define what a screw actually is, or explain why one type works where another fails.

This guide covers the full screw definition, every key part of the anatomy, the most important types and their real applications, and where the fastener industry is heading through 2030 and beyond.

What Is a Screw? A Clear, Precise Definition

A screw is a broad category of mechanical fastener featuring a threaded shaft designed to be driven into a material by rotational force, creating a secure, load-bearing joint without the need for a separate nut in most applications. The helical ridge — the thread — wraps around the cylindrical body and is what converts rotation into linear clamping force.designworldonline+1

That’s the short version. The longer one requires drawing a distinction that many people get wrong.

Screw vs. Bolt — They Are Not the Same Thing

The confusion between screws and bolts is genuinely common, even among people who work with them regularly. Here’s the functional difference:

A screw threads directly into a material (wood, metal, plastic, or a pre-tapped hole) and can be tightened or loosened without a second component.[en.wikipedia]

A bolt passes through materials and is secured on the opposite side with a nut. During assembly, it’s held stationary while the nut is torqued.[en.wikipedia]

So: an externally threaded fastener that forms its own mating thread as it’s driven in? That’s a screw. One that requires a nut to create clamping force? That’s a bolt. The distinction matters when you’re specifying parts for machinery, construction, or electronics — specifying the wrong one can result in assembly failure or unsafe joints.

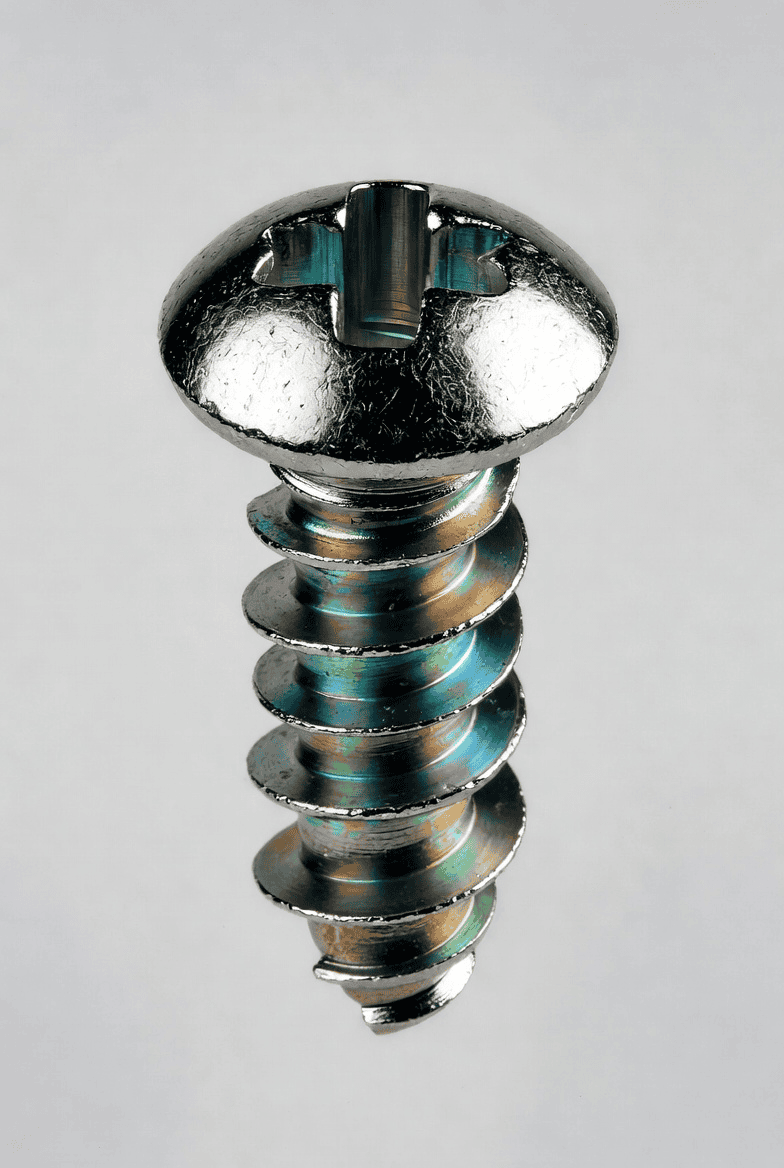

The Anatomy of a Screw: Five Parts That Do Real Work

Understanding the screw definition fully means understanding how each component contributes to function. A screw isn’t just “a pointy metal thing.” Every part has a job, and getting the wrong geometry for the wrong application creates real problems.[wilsongarner]

| Part | Location | Function |

|---|---|---|

| Head | Top of the screw | Bearing surface; transmits driving torque; determines final position |

| Drive (Recess) | Cavity in the head | Accepts the tool (screwdriver, bit, wrench); determines torque capacity |

| Shank | Body below the head | Provides tensile strength; may be partially or fully threaded |

| Thread | Helical ridge on shank | Converts rotational force to clamping force; grips material |

| Point (Tip) | Bottom end | Initiates penetration; determines whether pre-drilling is needed |

The Head

Head geometry isn’t cosmetic. A countersunk (flat) head sits flush with or below the surface — essential in applications where protrusion would interfere with mating parts or aesthetics. A pan head sits above the surface and provides a larger bearing area. A hex head allows wrench engagement for high-torque applications. Getting this choice wrong means either a surface that snags on other components or a fastener that can’t be tightened to the required clamp load.[chavesbao]

The Drive

The drive recess is where tool-to-fastener energy transfer happens. Slotted drives are universal but have low torque capacity — the screwdriver can slip sideways under load. Phillips (cruciform type H) drives are self-centering and ideal for production lines, but they’re deliberately designed to cam out under excessive torque, which prevents overtightening but frustrates anyone trying to apply high force manually. Torx (hexalobular) drives are the current standard for automated assembly — they transmit high torque reliably and resist cam-out far better than Phillips.[chavesbao]

The Thread

Thread geometry determines grip, pull-out strength, and compatibility with mating materials. The pitch — the distance between consecutive thread crests — governs how fast the screw advances per revolution and how much clamping force it generates. Coarse threads grip better in soft materials like wood; fine threads are used where vibration resistance is critical, such as in engine assemblies.[reddit]

Types of Screws: 10 You Actually Need to Know

There are hundreds of screw variants in the fastener catalog. What follows are the most widely used, with specific guidance on where each type genuinely belongs.[thefastenerdepot]

| Screw Type | Best Material | Defining Feature | Avoid Using For |

|---|---|---|---|

| Wood screw | Softwood, hardwood | Tapered shank; coarse deep thread | Metal; concrete |

| Machine screw | Metal (pre-tapped hole) | Uniform diameter; fine thread | Soft wood without insert |

| Self-tapping screw | Sheet metal, plastic | Cuts its own thread on entry | Cast iron; hardened steel |

| Lag screw | Heavy timber; masonry | Large hex head; very coarse thread | Thin materials; electronics |

| Set screw | Shafts, gears | Headless; fully embedded | Surface-visible joints |

| Sheet metal screw | Thin metal, HVAC | Sharp point; cutting threads | Structural timber loads |

| Floorboard screw | Flooring, subfloor | Wide head; thread-cutting tip | Any application above floor |

| Socket (Allen) screw | Machinery, automotive | Hex socket drive; high torque | Low-torque DIY assemblies |

| Flange screw | Automotive, steel frames | Built-in washer flange | Soft materials that crush |

| Security screw | Public fixtures, theft prevention | Tamper-resistant drive | Standard maintenance access |

monroeengineering+2

A few worth calling out in more detail:

Self-tapping screws eliminate the pre-drilling step, which makes them faster and more cost-effective in sheet metal and plastic assembly. However, the thread they cut is only as strong as the material surrounding it — in thin or soft metals, pull-out strength is significantly lower than in a properly tapped hole.[onlinelibrary.wiley]

Set screws deserve more attention than they typically get. Because they’re headless and seat flush inside a component (a gear, a collar, a pulley on a shaft), they’re invisible in the final assembly. The choice of point style — cup, cone, flat, or dog — determines whether the set screw bites into the shaft surface or presses against it, which directly affects resistance to rotational slipping.[fastenersystems]

Lag screws operate in a different weight class entirely. With diameters commonly ranging from 3/8″ to 3/4″ and hexagonal heads that require a wrench, these are structural fasteners used in deck construction, timber framing, and retaining walls — applications where a standard wood screw would simply shear or pull out under load.[thefastenerdepot]

Screw Materials and Coatings: A Choice That Determines Longevity

The alloy and surface treatment of a screw matters more than most buyers realize until something rusts through or fails under load.

| Material / Coating | Strength | Corrosion Resistance | Best Application |

|---|---|---|---|

| Carbon steel (zinc-plated) | High | Moderate (indoor) | General construction, dry environments |

| Stainless steel (304/316) | Medium-High | Excellent | Outdoor, marine, food-grade |

| Alloy steel (hardened) | Very High | Low (needs coating) | High-stress mechanical assemblies |

| Brass | Low-Medium | Very Good | Electrical, decorative |

| Titanium | High | Excellent | Aerospace, medical implants |

| Black oxide | — (surface only) | Marginal | Indoor tools, firearms |

| Hot-dip galvanized | — (surface only) | Very Good | Outdoor structural timber |

The 316 stainless grade is worth specifying specifically for marine environments — not just generic “stainless.” The difference between 304 and 316 stainless is the addition of molybdenum in 316, which provides significantly better resistance to chloride corrosion (saltwater, de-icing salts). Using 304 in a marine application is a common and expensive mistake.

Industry Applications: Where Screws Do Critical Work

The screw definition in textbooks describes a fastener. In practice, screws are structural and safety-critical components across virtually every manufacturing sector.[finance.yahoo]

Construction and Infrastructure

Screws are used in everything from timber framing (lag screws, structural wood screws) to drywall installation (coarse-thread drywall screws) to steel stud framing (self-drilling screws). In cold-formed steel construction, screw connection performance under cyclic shear loading has been extensively studied — research confirms that screw head type and the use of washers significantly affects load capacity and failure mode under dynamic loading.[onlinelibrary.wiley]

Automotive Manufacturing

Modern vehicle assembly uses screws in the thousands — machine screws for body panels, flange screws for engine components, set screws for steering column assemblies. The automotive sector is one of the primary demand drivers for the global fastener market. Flexibility in removability — the ability to disassemble, service, and reassemble — makes screws the preferred fastener over welding or adhesive bonding wherever maintenance access is needed.[finance.yahoo]

Aerospace

Weight-to-strength ratio is the dominant specification here. Titanium screws are used in airframe and engine applications where alloy steel would add unacceptable mass. Thread locking compounds (Loctite, anaerobic adhesives) or mechanical locking features are mandatory in many aerospace joints to prevent loosening under vibration. Tolerances are tighter — thread gauging is part of every incoming inspection.

Electronics and Precision Instruments

Miniaturization drives demand for M2, M1.6, and even sub-millimeter screws. Machine screws in stainless steel or brass are standard for circuit board mounting, enclosure assembly, and heat sink attachment. The growing consumer electronics market — smartphones, wearables, laptops — continues to drive demand for precision micro-fasteners.[futuremarketreport]

Medical and Orthopedic Devices

This is where screw engineering reaches its most demanding application. Orthopedic bone screws must achieve strong fixation in cancellous and cortical bone without stripping, while remaining biocompatible and MRI-safe. Novel dual-threaded pedicle screws have been shown to provide fixation stability comparable to traditional designs while preserving more bone volume. The bone-screw-fastener concept introduced a circumferential interlocking interface between implant and bone specifically designed to resist stripping under multi-axial loading forces.pmc.ncbi.nlm.nih+1

The Global Screw Fastener Market: Size, Growth, and What’s Driving It

The numbers tell a clear story about how fundamental screws are to modern industry.

The global industrial fasteners market — which includes screws, bolts, nuts, rivets, and washers — was valued at $113.2 billion in 2024, with North America projected to hold a 27.3% share by 2034. Within that, the screw fasteners segment specifically was valued at $14,500.75 million in 2024, growing at a CAGR of 6.32% through 2032.factmr+1

The screw segment is expected to maintain market leadership within fasteners for several reasons:[finance.yahoo]

Wide material compatibility — screws work in wood, metal, plastic, composite materials, and more

No secondary component required — unlike bolts, which need nuts and often washers

Removability — critical for maintenance and repair in automotive and aerospace applications

Variety of specialized types — the catalog of screw variants continues to expand as new materials and applications emerge

Growth is being driven by expanding construction activity in South and Southeast Asia, increasing vehicle production globally, and the continued growth of consumer electronics manufacturing.futuremarketreport+1

Future Trends in Screw Technology

The screw is thousands of years old as a concept. The innovation happening right now, though, is genuinely significant.

Miniaturization and Precision Micro-fasteners

The demand for screws below 1mm in diameter is growing rapidly, driven by wearables, hearing aids, and implantable medical devices. Manufacturing tolerances at this scale require specialized forming and inspection equipment.

Smart Fasteners with Embedded Sensing

Research programs at automotive and aerospace OEMs are developing screws with embedded strain gauges or RFID chips, allowing real-time monitoring of clamp load throughout a structure’s service life. This would move fastener inspection from periodic manual checks to continuous digital monitoring.

Sustainable Materials and Coatings

Increasing ESG requirements from major industrial buyers are pushing fastener manufacturers toward chrome-free corrosion-resistant coatings, recycled-content steel alloys, and reduced-VOC thread-locking compounds. The screw fasteners market reflects this trend — manufacturers adopting eco-friendly production methods are gaining preference in procurement decisions.[futuremarketreport]

Additive Manufacturing for Specialty Applications

3D-printed screws in composite polymers and exotic alloys are beginning to appear in low-volume aerospace and medical applications where traditional machining would be cost-prohibitive. Studies comparing 3D-printed fastener strength against injection-molded equivalents show promising results for specific load profiles.[dergipark.org]

Self-Drilling and Self-Tapping Advances

The construction industry continues to push for faster installation. Next-generation self-tapping screws with compound drill-point geometries reduce installation torque requirements while maintaining pull-out strength, reducing tool fatigue in high-volume applications.

How to Choose the Right Screw: A Practical Decision Framework

This is where most general guides fall short — they describe types without giving you a decision structure. Here’s a working framework:

Step 1 — Identify the base material. Wood, metal, plastic, and concrete each require fundamentally different thread forms. Starting with the material eliminates most wrong choices immediately.

Step 2 — Determine the load type. Is the screw resisting pull-out (axial load), shear (lateral load), or both? Axial loads favor coarse, deep threads. Shear loads favor larger shank diameters and partial threading.

Step 3 — Consider the environment. Indoor, dry? Carbon steel with zinc plating is sufficient. Outdoor, coastal? Specify 316 stainless or hot-dip galvanized. Food processing or medical? Stainless only, with passivation.

Step 4 — Check accessibility and tool clearance. A socket screw requires clearance for an Allen key or hex socket. A hex head requires wrench swing. In tight assemblies, drive type can become the limiting constraint.

Step 5 — Decide on removability. If the joint will never need disassembly, a thread-locking compound can be applied. If regular maintenance access is required, avoid permanent locking methods and consider a nylon-insert (nylock) nut or a split-lock washer instead.

Recommended Equipment for Industrial Fastener Production

For manufacturers involved in fastener production and precision assembly, screw production line specification and quality control are critical decisions. We recommend evaluating equipment and materials from established suppliers with documented quality systems and traceable material certifications.

Sinofude Technology — Precision candy and confectionery production equipment; explore production line solutions at sinofudetechnology.com

Authoritative External References

Wikipedia — Screw (fastener definition and bolt distinction) (DA 90+): en.wikipedia.org/wiki/Screw

Design World — What Are Screws? (Technical overview by Dr. Jody Muelaner) (DA 55+): designworldonline.com/what-are-screws

Future Market Report — Screw Fasteners Market Size & CAGR Forecast to 2032 (DA 50+): futuremarketreport.com

Fact.MR — Industrial Fastener Market Size & Share 2024 (DA 55+): factmr.com/report/industrial-fasteners-market

The Fastener Depot — Types of Screws: Comprehensive Guide (DA 45+): thefastenerdepot.com/blogs/news/types-of-screws