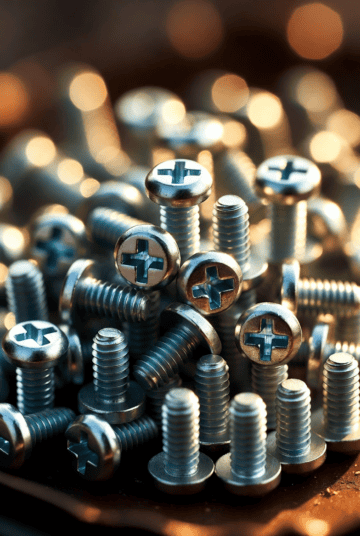

Let us start with the most expensive mistake you can make in a workshop: grabbing a bolt from the “general bin” and threading it into an aluminum engine component because it fits the hole. It threads in smoothly for the first two turns, then suddenly feels snug. So you apply more torque. The threads strip. And now you’re looking at a repair that costs ten times more than the original job. That is what happens when you ignore vehicle threads. The correct way to approach this: identify the thread system first (metric vs. unified, coarse vs. fine), match the pitch precisely, and verify the tolerance class before applying any torque. Everything else follows from that sequence.

Why Getting Vehicle Threads Wrong Costs More Than You Think

The problem is almost never about not knowing that thread standards exist. Most mechanics, engineers, and buyers know that automotive fasteners come in different systems. The real issue is that, without a reliable reference, these distinctions blur under deadline pressure or when you’re sourcing replacement parts at speed.

We once worked on a German-manufactured vehicle’s cylinder head reinstall. The spark plug holes had been previously worked on by a shop that used a 1/4-28 UNF bolt — dimensionally close to M6 metric — but with a completely different thread angle and pitch. The result? The aluminum threads had already begun deforming. Two hours of remediation work, a Helicoil insert, and a lot of frustration that could have been avoided with a $15 thread gauge.

The two most common causes of thread mismatch in vehicle work:

Confusing nominal diameter (the number on the label) with actual thread pitch and angle

Mixing fasteners from different production eras, especially on imports where partial-year changeovers happened

The fix starts with a simple rule: read the specification label fully, not just the diameter. A bolt labeled M10×1.5 and a bolt labeled M10×1.25 have identical outer diameters but entirely different thread densities. Treat them as interchangeable, and you will pay for it.

The Anatomy of a Vehicle Thread: What Every Spec Label Actually Means

Before choosing any vehicle thread type, you need to be able to read the specification language without guessing. Here is exactly what each part of a thread label tells you:

For Metric threads (e.g., M10 × 1.5):

M = Metric designation (ISO standard)

10 = Nominal major diameter in millimeters

× 1.5 = Thread pitch in millimeters (distance from crest to crest)

For Unified Inch threads (e.g., 3/8-24 UNF):

3/8 = Nominal major diameter in inches

24 = Threads Per Inch (TPI)

UNF = Unified National Fine (versus UNC = Unified National Coarse)

Additional specification elements you’ll see on technical drawings:

Tolerance class (e.g., 6g/6H for metric, 2A/2B for unified) — controls how tightly the male and female threads mate

Thread depth and engagement length — especially critical when threading into soft metals like aluminum or magnesium alloy castings

Thread direction — almost all vehicle threads are right-hand (clockwise to tighten), except specific components like left-side wheel lug nuts on older vehicles

Understanding these elements eliminates the most common sourcing error: ordering by diameter alone.[elginscrewsandbolts]

The Four Main Vehicle Thread Systems: UNC, UNF, Metric Coarse, and Metric Fine

Not all vehicle threads are created equal. Four primary systems govern nearly all automotive fastener specifications globally, and each serves a distinct engineering purpose.[monsterbolts]

Unified National Coarse (UNC): Fewer threads per inch, deeper thread profile. Easier to assemble in field conditions because the coarser profile is more tolerant of dirt, minor damage, and misalignment. Common in general body work, brackets, and non-critical assemblies.

Unified National Fine (UNF): More threads per inch, shallower but denser engagement. The increased thread contact area provides roughly 15–20% higher tensile stress resistance compared to the equivalent UNC diameter — which is why UNF dominates in brake systems, suspension joints, and safety-critical connections that experience high vibration.[monsterbolts]

Metric Coarse (MC): The global default for automotive manufacturing since the 1970s. Standard pitch for general structural applications (e.g., M8×1.25, M10×1.5). Used by every major OEM in non-safety-critical assemblies worldwide.[albanycountyfasteners]

Metric Fine (MF): Smaller pitch than coarse for the same nominal diameter. Provides finer torque control, higher fatigue resistance, and better holding in thin-walled components — which is why it’s the default choice in EV battery enclosures and lightweight aluminum chassis joints.[albanycountyfasteners]

Table 1: Four Primary Vehicle Thread Systems — Side-by-Side Comparison

| Thread System | Origin Standard | Thread Density | Vibration Resistance | Best-Fit Vehicle Location |

|---|---|---|---|---|

| UNC | ANSI/ASME B1.1 | Low (coarse pitch) | Moderate | Body panels, brackets, general assembly |

| UNF | ANSI/ASME B1.1 | High (fine pitch) | High | Brake calipers, suspension, precision mounts |

| Metric Coarse | ISO 261 | Medium | Moderate | Engine block, transmission housing, general drivetrain |

| Metric Fine | ISO 261 | High (fine pitch) | Very High | Aluminum castings, EV chassis, precision adjustment |

One practical note that most guides skip: never apply UNF torque specs to UNC fasteners of the same nominal diameter. Because UNF threads have a larger tensile stress area, they can tolerate higher preload. Apply that same torque to UNC, and you risk exceeding yield point, especially in heat-affected zones near the exhaust system.[machining-custom]

Thread Selection by Vehicle Location: A Practical Decision Map

Knowing the thread systems is step one. Knowing which system belongs where in an actual vehicle is the part most guides don’t cover. Here’s the breakdown, built from real assembly work:

Engine Block and Head: Metric coarse is standard for most modern engines. Head bolts often use fine pitch on the nut side and coarse on the block side — specifically because the aluminum block requires more thread engagement to distribute load, while the nut side benefits from the finer pitch for precise torque control.[agcoauto]

Brake System (calipers, brake lines, master cylinder banjo bolts): This is where UNF, or metric fine equivalent, is non-negotiable. Brake line fittings in North American vehicles are typically 3/8-24 UNF. European systems use M10×1.0 or M12×1.0 metric fine. Using coarse-pitch threads in these locations is a safety failure, not just a mechanical one.

Suspension and Steering Components: High dynamic load, constant vibration. Both UNF and metric fine perform here, but the key variable is the base material. Steel-to-steel joints can tolerate coarse thread; aluminum knuckles, strut towers, and control arm mounts require fine pitch to prevent fretting and loosening.[rlfasteners]

Interior Trim and Dashboard: This is where coarse threads — and increasingly, thread-forming screws — dominate. The material is often plastic or thin sheet steel. Overtorquing even a UNC fastener here strips the surrounding material instantly.

Table 2: Thread Selection by Vehicle Location

| Vehicle Location | Recommended Thread System | Tolerance Class | Common Failure If Wrong Thread Used |

|---|---|---|---|

| Engine block / cylinder head | Metric Coarse (block side) + Metric Fine (nut side) | 6H / 6g | Stripped aluminum threads under thermal expansion |

| Brake system line fittings | UNF 3/8-24 or M10×1.0 Metric Fine | 3A / 3B or 6g/6H | Fluid leak under pressure, brake failure |

| Suspension joints (aluminum) | Metric Fine or UNF | 2A / 2B or 6g/6H | Thread fretting, fastener loosening under vibration |

| Body panels and brackets | UNC or Metric Coarse | 2A / 2B | Stripped holes from overtorque (acceptable risk zone) |

| Interior trim / plastic panels | Coarse or thread-forming screws | N/A (self-tapping) | Boss fracture, clip failure |

Thread Damage, Repair, and Helicoil Inserts: What Works and What Doesn’t

The Problem: Stripped vehicle threads in aluminum components — spark plug holes, oil drain pans, brake caliper mounting points — are arguably the most common fastener-related repair job in any shop. The question isn’t whether you’ll encounter stripped threads; it’s whether you’ll fix them correctly.

The Cause: Almost always a combination of two things: wrong thread pitch was used initially, or correct torque spec was ignored. Aluminum’s thread shear strength is roughly one-third that of steel. Apply steel-spec torque to an aluminum casting, and the threads yield.

The Step-by-Step Repair Protocol (Helicoil method):

Select the correct Helicoil kit matched to the original thread specification — not one size up, not a generic kit. For M10×1.5, use an M10×1.5 Helicoil insert.

Drill out the damaged threads using the drill bit specified in the kit (e.g., 10.5mm for M10 inserts). Do not freehand this. Use a drill guide or mill to stay perpendicular to the surface.

Tap the new hole using the Helicoil tap included in the kit. The tap creates threads sized for the insert, not for the original bolt.

Install the Helicoil insert using the installation tool until the top coil sits 0.5–1 turn below the surface.

Break off the tang (the installation drive notch) using the provided punch tool.

Verify thread engagement by threading in the original bolt by hand. It should run smoothly through the full engagement length without resistance.[rlfasteners]

Common Misconception: Many technicians think a Helicoil is a “permanent” fix only in extreme cases. In reality, a properly installed Helicoil in aluminum provides stronger thread engagement than the original cast threads — because the steel coil distributes load across a larger surface area. It’s not a compromise; it’s often an upgrade.[rlfasteners]

Industry Applications: Where Vehicle Threads Go Beyond Standard Assembly

A standard passenger vehicle contains more than 3,500 fasteners — and every single one is a thread specification decision. Beyond everyday assembly, vehicle threads play a critical structural role in several specialized sectors:[fictiv]

Motorsport and High-Performance Engineering: Racing teams routinely switch to titanium or inconel fasteners with aerospace-grade UNF or metric fine threads. The priority is weight reduction and fatigue resistance under extreme thermal cycling. Thread-locking compounds replace conventional washers entirely in many applications.[machining-custom]

Electric Vehicle (EV) Battery and Chassis Design: EV battery enclosures face a unique engineering challenge: the combination of high-voltage electrical isolation requirements and structural load demands. Metric fine threads in non-ferrous materials (aluminum, magnesium alloy) are almost universally specified here because they provide the precision preload control needed for electrical sealing gaskets.[fictiv]

Aluminum-Intensive and Lightweight Vehicles: As reviewed in published materials science research, aluminum matrix composites are increasingly used in vehicle body and power systems — and their fastener specifications depart sharply from traditional steel-centric standards. Thread engagement length, insert specifications, and anti-galling coatings all become primary engineering decisions, not afterthoughts.[linkinghub.elsevier]

Threaded Connection Sealing (Piping and Fluid Systems): In fluid circuits, vehicle threads directly affect sealing performance. Research modeling surface roughness and gas flow in threaded connections demonstrates that even a 22% variation in contact pressure — achievable through thread tolerance changes alone — significantly impacts leak resistance.[mdpi]

Future Trends in Automotive Fastener Thread Technology

The automotive fastener space is not static. Four converging forces are actively reshaping how vehicle threads are specified, manufactured, and maintained.

Table 3: Future Trends in Automotive Thread Technology

| Trend | What’s Driving It | Impact on Thread Specification | Recommended Action |

|---|---|---|---|

| EV lightweighting with aluminum/magnesium alloys | Range optimization, battery weight reduction | Metric Fine becomes the default; thread engagement length increases | Shift purchasing standards toward MF; audit torque specs for all new platforms |

| Anti-corrosion coating advances | EV underbody exposure, global climate variance | Coated threads alter effective pitch diameter; torque tables must be recalculated | Never apply dry-thread torque specs to coated fasteners without correction factor |

| Digital torque traceability (Industry 4.0) | OEM quality mandates, liability reduction | Thread tolerance classes tightened to 3A/3B for critical joints | Invest in torque audit systems for production lines handling safety-critical assemblies |

| Thread-forming (chipless) fasteners in thin-wall EV components | Eliminate tapping process; reduce assembly steps | Changes thread geometry fundamentally; incompatible with standard replacement bolts | Source thread-forming fastener specs from OEM service manuals only |

Vehicle threads are not a footnote in automotive engineering — they are the mechanical grammar that holds every assembly together. Whether you are rebuilding a suspension on a classic import, specifying fasteners for a new EV platform, or simply replacing a brake caliper bolt, the same principle applies: know the thread, know the material, know the load. That sequence, applied consistently, is what separates a job done right from a job done twice.

Common Types of Automotive Fasteners — Wilson-Garner

https://wilsongarner.com/common-types-of-automotive-fasteners/UNC vs UNF vs Metric Threads: Thread Pitches, Fit Classes, Where Each Shines — Monster Bolts

https://monsterbolts.com/blogs/news/unc-vs-unf-vs-metric-threads-thread-pitches-fit-classes-where-each-shinesAutomotive Fastener Threads Types — Classics on Autotrader

https://classics.autotrader.com/articles/automotive-fastener-threads-typesThread Types for Screws and Fasteners — Elgin Screws & Bolts

https://elginscrewsandbolts.com/pages/thread-types-for-screws-and-fastenersMost Common Types of Automotive Fasteners Explained — Fictiv

https://www.fictiv.com/articles/types-of-automotive-fasteners-explained